IGBT module for electric automobile

A technology for electric vehicles and electrode terminals, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as long heat dissipation paths and thermal fatigue of internal materials, so as to improve product operation reliability, reduce heat conduction paths, and improve heat conduction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

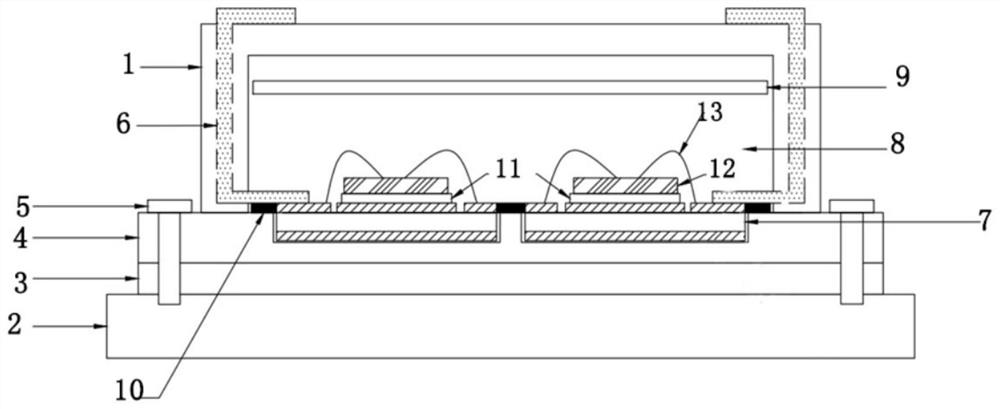

[0024] An IGBT module for electric vehicles, such as figure 1 , including a radiator 2, a substrate 4 is fixed on the top layer of the radiator 2, a housing 1 is fixed on the top of the substrate 4, a groove is opened on the top of the substrate 4 in the housing 1, a DBC7 is arranged in the groove, and the top of the DBC7 is placed There is a chip 12, the chip 12 is welded to the DBC7 through the solder layer 11, the top copper layer surface of the DBC7 is electrically connected to the chip 12 through the bonding wire 13, the top copper layer surface of the DBC7 is also connected to the electrode terminal 6, and the electrode terminal 6 is embedded in the shell 1 Inside, one end of the electrode terminal 6 protrudes from the inner wall of the shell 1, and is electrically connected to the DBC7 by means of ultrasonic welding, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com