Device and method for measuring laser-damaged three-dimensional structure

A technology for measuring laser and three-dimensional, which is applied in measuring devices, optical testing of flaws/defects, material analysis through optical means, etc. It can solve the problem of time-consuming and labor-intensive detection, inability to detect depth information of damage, complex and expensive operation of detection equipment and other problems, to achieve the effect of increasing practicability, simple structure, and non-destructive measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

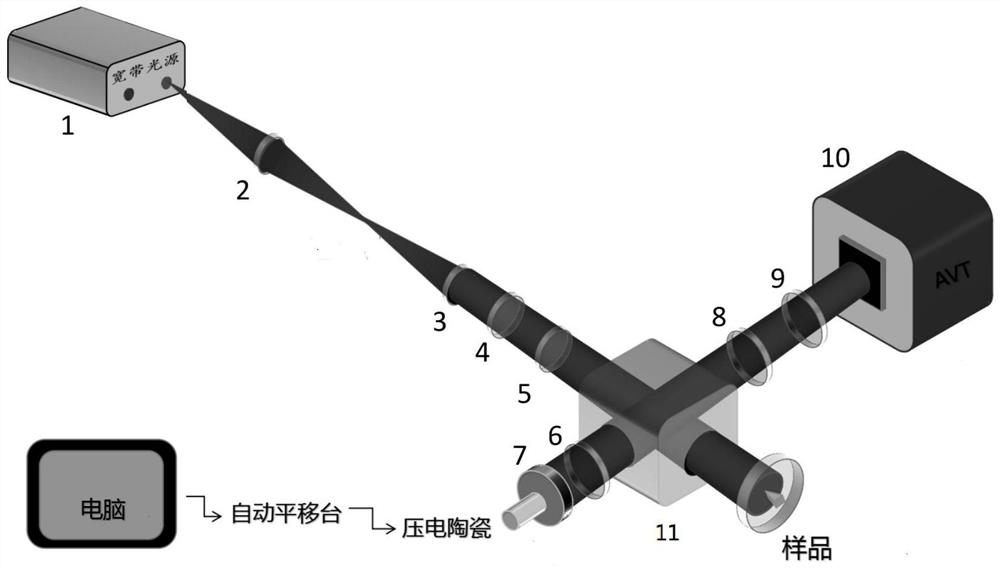

[0033] Such as figure 1 As shown, the device for realizing laser three-dimensional damage measurement based on phase-shift digital holography technology of the present invention includes a superluminescent light-emitting diode light source 1, a focusing lens 2, a collimating lens 3, an attenuation plate 4, a polarizer 5, and a beam-splitting prism 11. Quarter wave plate 6, reflecting mirror 7, imaging lens 8, analyzer 9, imaging device 10; Described superluminescent light-emitting diode light source 1 vertically places focusing lens 2 and collimating lens 3 along this laser beam direction, after that Attenuation sheet 4, polarizer 5 and beam splitting prism 11 are arranged in sequence; beam splitting prism 11 divides the light beam into reflected beam and transmitted beam, and a quarter wave plate 6, reflector 7, piezoelectric ceramics, electric Control the translation platform, and the electric control translation platform is connected with the computer. A polarizer 8, an im...

Embodiment 2

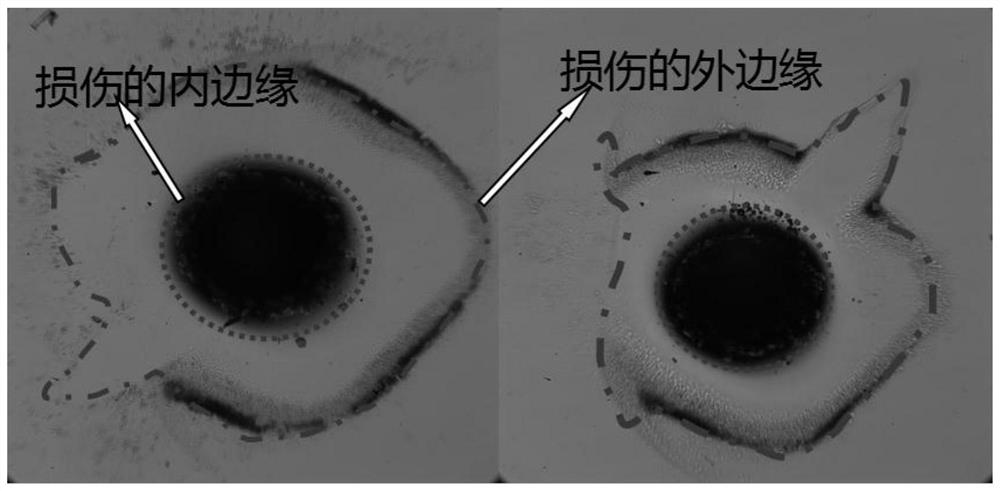

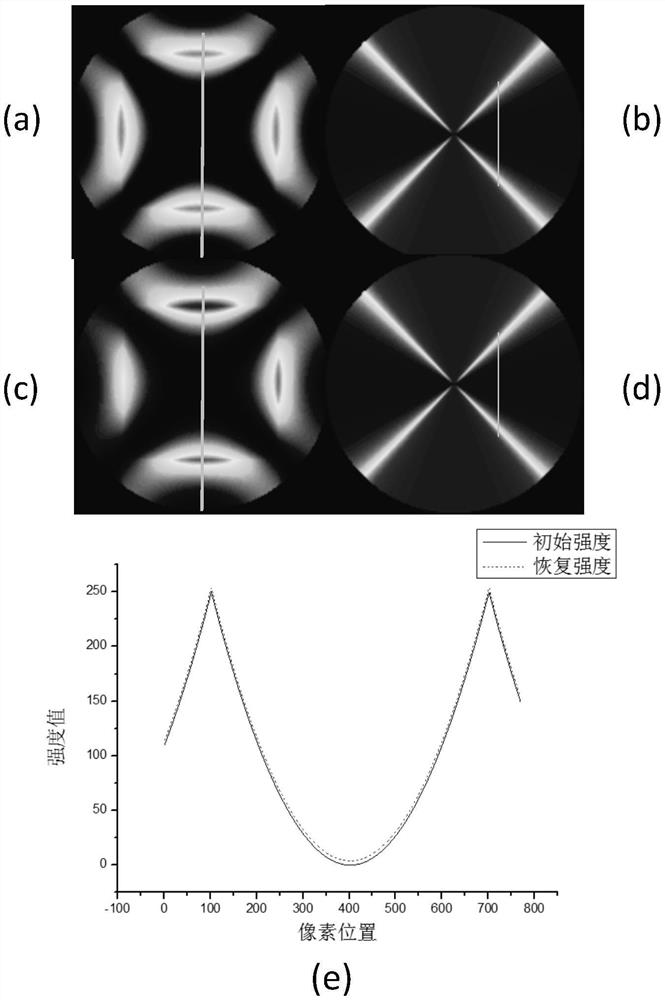

[0036]The three-dimensional laser damage is measured by using the phase-shift digital holography technology designed in Example 1. The damage size in the damaged sample used is about 2.5 mm, and the residual stress depth area is about 200-300 microns. Build the measuring device according to the mode of embodiment 1, because the focal length of imaging lens 8 is 8 centimeters, so in order to obtain a magnified clear image, need to be placed on the sample to be measured and the position of distance 13.5 centimeters from imaging lens 8, and from imaging lens The distance from 8 to the target surface of imaging device 10 is about 28.5 centimeters. The minimum pixel unit of the imaging device 10 is 7.4 microns, and its resolution is 2048×2048. When the distance between the imaging device and the imaging lens exceeds 0.5cm on the basis of 28.5cm, it will cause defocus and unclear imaging.

[0037] In the detection process, open the superluminescent light-emitting diode light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com