A heat transfer method based on the heat transfer structure of a full-layer steel high-pressure hydrogen storage vessel

A technology of a hydrogen storage container and a heat exchange structure, applied in the field of hydrogen energy, can solve the problems of large wall thickness of the container, inability to exchange heat inside, and difficulty in heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

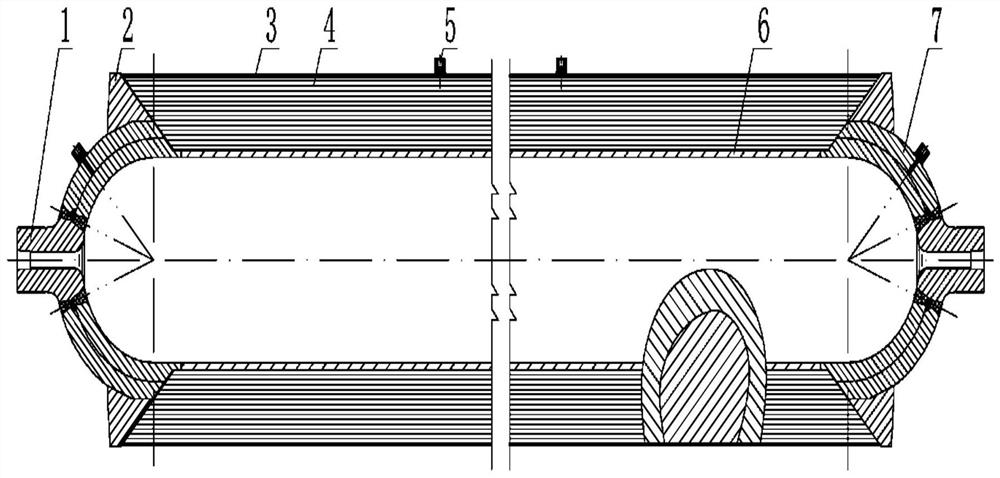

[0040] Such as figure 1 As shown, a typical structure of a fully multi-layer steel high-pressure hydrogen storage container includes an interface seat 1, a reinforcing hoop 2, a protective shell 3, a steel belt layer 4, a hydrogen sensor interface 5, an inner cylinder 6 and a head 7. In addition to having sufficient pressure bearing capacity, the heat exchange function is the key to realize the solid-state / high-pressure hybrid hydrogen storage technology of the all-multilayer steel high-pressure hydrogen storage container.

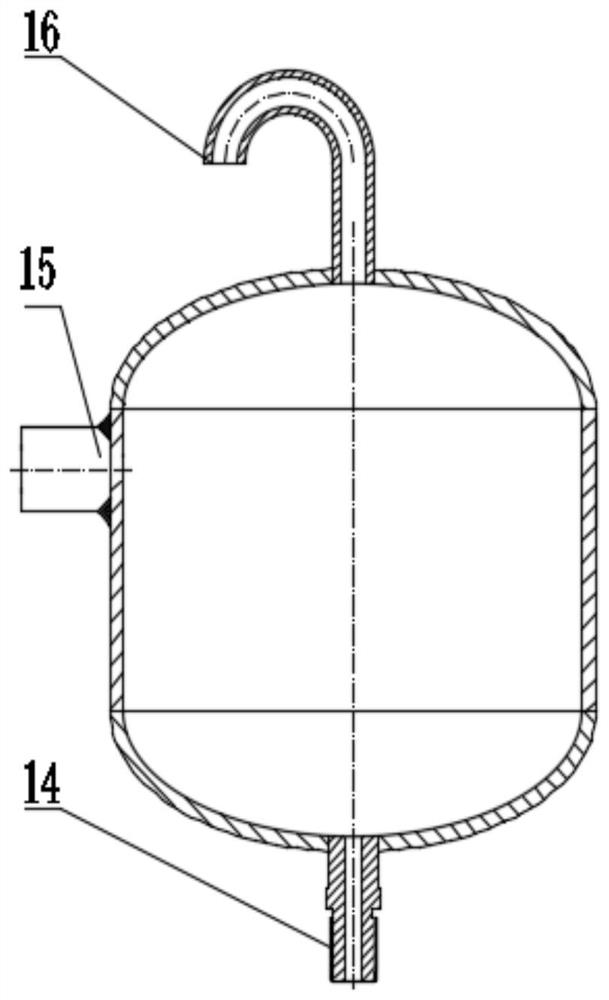

[0041] The heat exchange structure of the full-layer steel high-pressure hydrogen storage vessel in this embodiment is as follows: figure 2 As shown, it includes a protective shell 3 , a protective shell medium inlet joint 11 , a protective shell medium outlet joint 9 , an oil tank 8 , a saddle 12 , a jacket 10 and a baffle 13 . The protective shell 3 is welded to the reinforcement hoops 2 at the left and right ends of the full-layer steel high-pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com