Cable

A cable and cable core technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems affecting performance, short service life of cables and wires, friction damage between the outer layer and the ground, etc., to increase service life and increase heat dissipation performance, the effect of preventing contact with the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

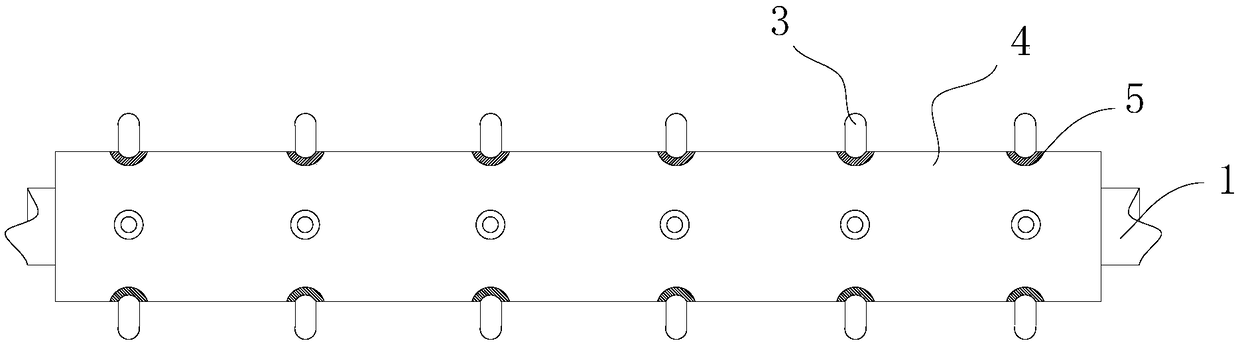

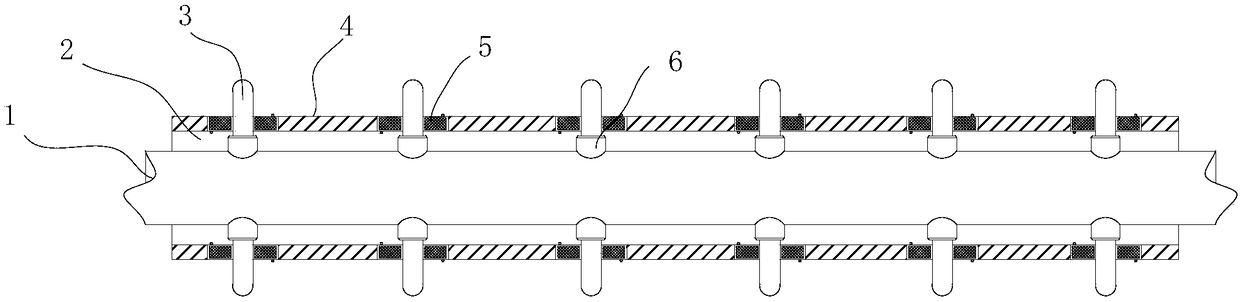

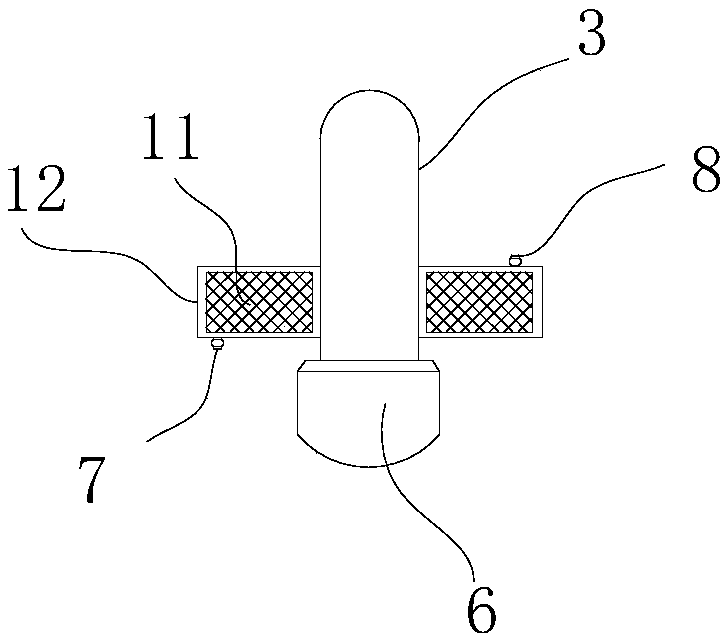

[0018] Such as figure 1 with figure 2 As shown, a cable includes a cable outer layer 4, a housing cavity 2 is provided in the middle of the cable outer coating layer 4, and a cable core 1 is arranged in the housing cavity 2, and the cable core 1 includes an inner core wire and an inner protective layer, and the inner core The wire is arranged in the inner protective layer, and the outer part of the inner protective layer is integrally injection-molded with more than one fixed bushing 6;

[0019] A pin hole is arranged in the middle of the fixed shaft sleeve 6, and a pin 3 is inserted in each pin hole, and a mounting hole is opened on the cable outer layer 4 facing each pin 3, and a mounting hole is installed in each mounting hole. Insert the suction piece 5, and the middle of the suction piece 5 is provided with a through hole facing each pin 3, and the pin 3 passes through the through hole in the middle of each suction piece 5 and protrudes from the outer layer 4 of the cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com