High-cost-performance stainless steel composite pipeline

A composite pipe, stainless steel technology, applied in rigid pipes, pipe protection, and protection of pipes through thermal insulation, etc., can solve the problems of no heat preservation function, high comprehensive cost performance, and stainless steel pipes cannot be directly buried in the ground, so as to inhibit the growth of microorganisms. Comprehensive cost-effective, multi-color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

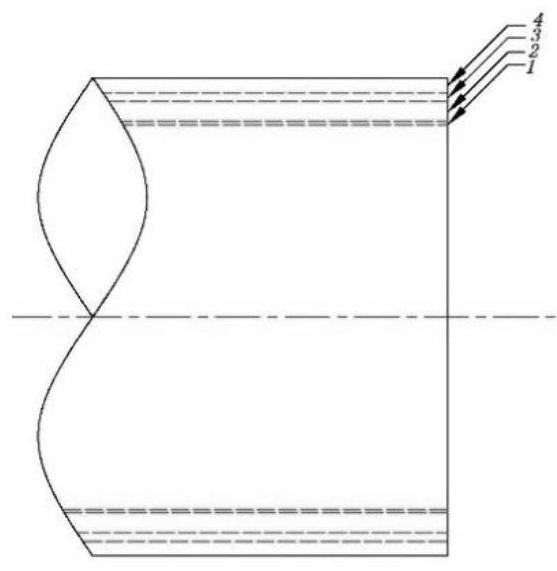

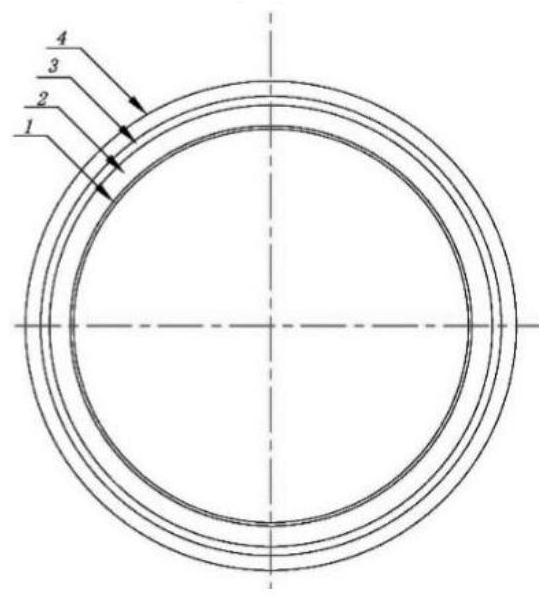

[0044] The thin-walled stainless steel is made of high corrosion-resistant alloy material, specifically 304 stainless steel; the insulating fixing layer is made of plastic material, specifically polyethylene; Not limited to any one or combination of glass fiber, galvanized steel wire, and copper-plated steel wire (glass fiber, galvanized steel wire in this embodiment, the same below); the outer anti-corrosion layer is made of plastic, specifically polyethylene.

[0045]Further, the thickness of the thin-walled stainless steel is 2 mm, the thickness of the pressure-bearing reinforcement layer is 6.5 mm, the thickness of the insulating fixing layer is 10 mm, and the thickness of the outer anti-corrosion layer is 12 mm.

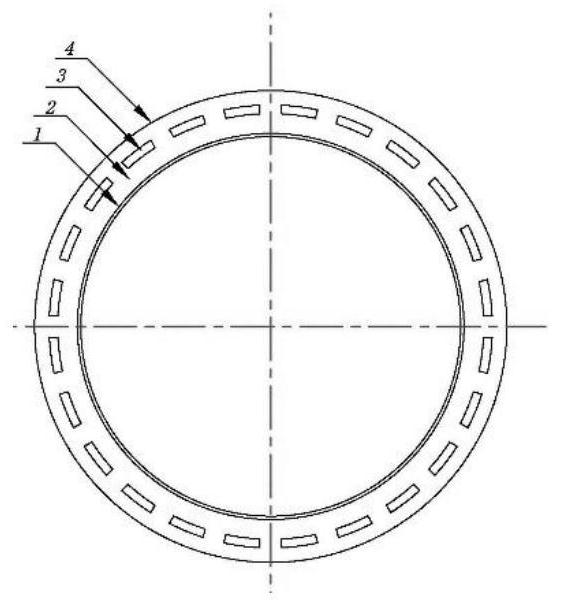

[0046] The pressure-bearing reinforcement layer is composite steel with porous structure. The circular hole of the porous structure (opening width-to-thickness ratio is 2.1), the outer anti-corrosion layer and the insulating fixing layer are riveted into one bod...

Embodiment 2

[0048] The thin-walled stainless steel is made of high corrosion-resistant alloy material, specifically 304 stainless steel; the insulating fixing layer is made of plastic material, specifically polypropylene; the pressure-bearing reinforcement layer is woven with high compressive and tensile fiber / alloy wire, and the material is selected from glass Fiber, galvanized steel wire; the outer anti-corrosion layer is made of plastic material, specifically polypropylene.

[0049] Further, the thickness of the thin-walled stainless steel is 2 mm, the thickness of the pressure-bearing reinforcement layer is 7 mm, the thickness of the insulating fixing layer is 10 mm, and the thickness of the outer anti-corrosion layer is 12 mm.

[0050] The pressure-bearing reinforcement layer is composite steel with porous structure. The circular hole of the porous structure (opening width-to-thickness ratio is 2.0), the outer anti-corrosion layer and the insulating fixing layer are riveted together ...

Embodiment 3

[0052] The thin-walled stainless steel is made of high corrosion-resistant alloy material, specifically 316L stainless steel; the insulating fixing layer is made of plastic material, specifically polyvinyl chloride; the pressure-bearing reinforcement layer is woven with high compressive and tensile fiber / alloy wire, and the material is selected from Glass fiber, galvanized steel wire; the outer anti-corrosion layer is made of plastic material, specifically polyvinyl chloride.

[0053] Further, the thickness of the thin-walled stainless steel is 2 mm, the thickness of the pressure-bearing reinforcement layer is 7 mm, the thickness of the insulating fixing layer is 10 mm, and the thickness of the outer anti-corrosion layer is 12 mm.

[0054] The pressure-bearing reinforcement layer is composite steel with porous structure. The circular hole of the porous structure (opening width-to-thickness ratio is 2.1), the outer anti-corrosion layer and the insulating fixing layer are rivete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com