Functionally gradient crash barrier and construction method thereof

A technology of anti-collision guardrails and functional gradients, which is applied to bridge parts, erection/assembly of bridges, bridge materials, etc., can solve the problems of large impact force, easy failure, and high maintenance cost for drivers and passengers, so as to ensure construction quality and construction Efficiency, superior impact resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

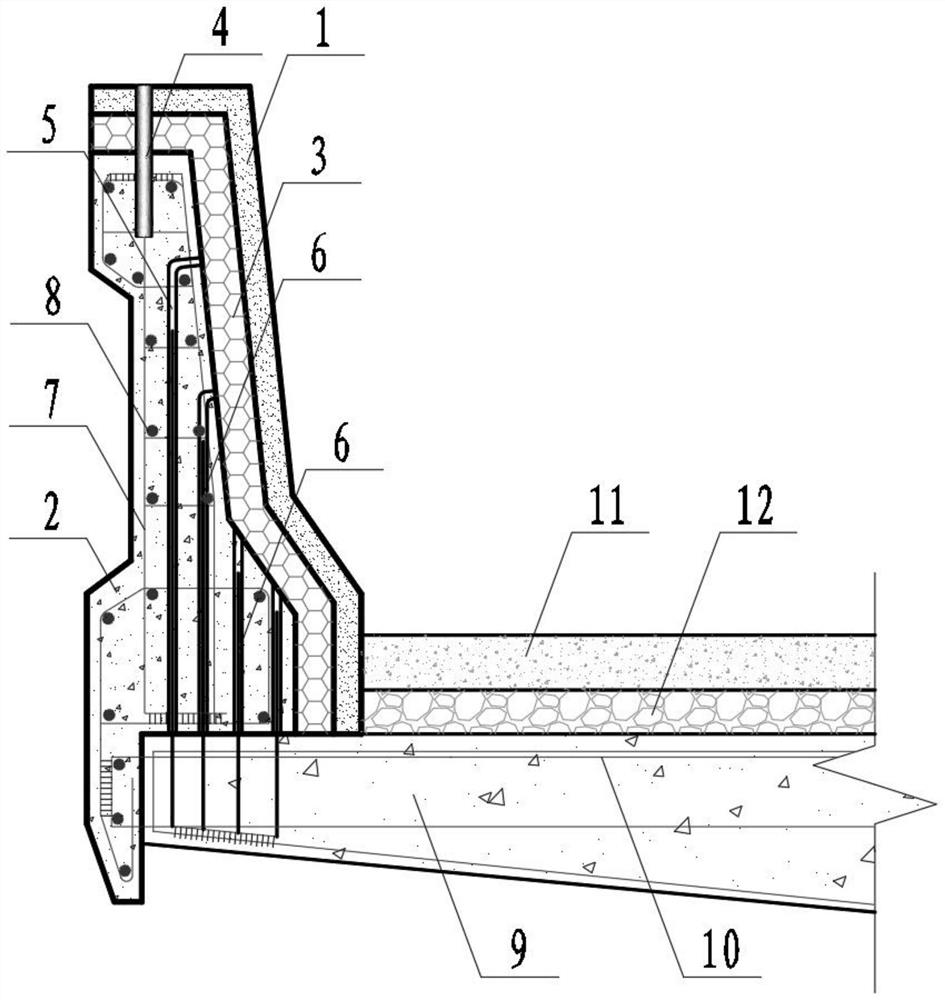

[0044] Such as figure 1 As shown, the functional gradient crash barrier of this embodiment includes a base 2, an energy dissipation layer 3, a UHPC panel 1 and an energy dissipation connector 4, and the energy dissipation layer 3 is arranged between the base 2 and the UHPC panel 1, and the base The seat 2, the energy dissipation layer 3 and the UHPC panel 1 are connected as a whole through the energy dissipation connector 4, and there are one or more energy dissipation connectors 4 (only one is shown in the figure).

[0045] In this embodiment, the guardrail is installed on the cantilever arm 9 of the beam body, and the steel bar 6 required for the connection with the base 2 is reserved on the cantilever arm 9 of the beam body, and the steel bar in the beam body is pre-embedded in the cantilever arm 9 of the beam body.

[0046] In this embodiment, the energy-dissipating connector 4 runs through the UHPC panel 1 and the energy-dissipating layer 3 , and extends into the base 2 ,...

Embodiment 2

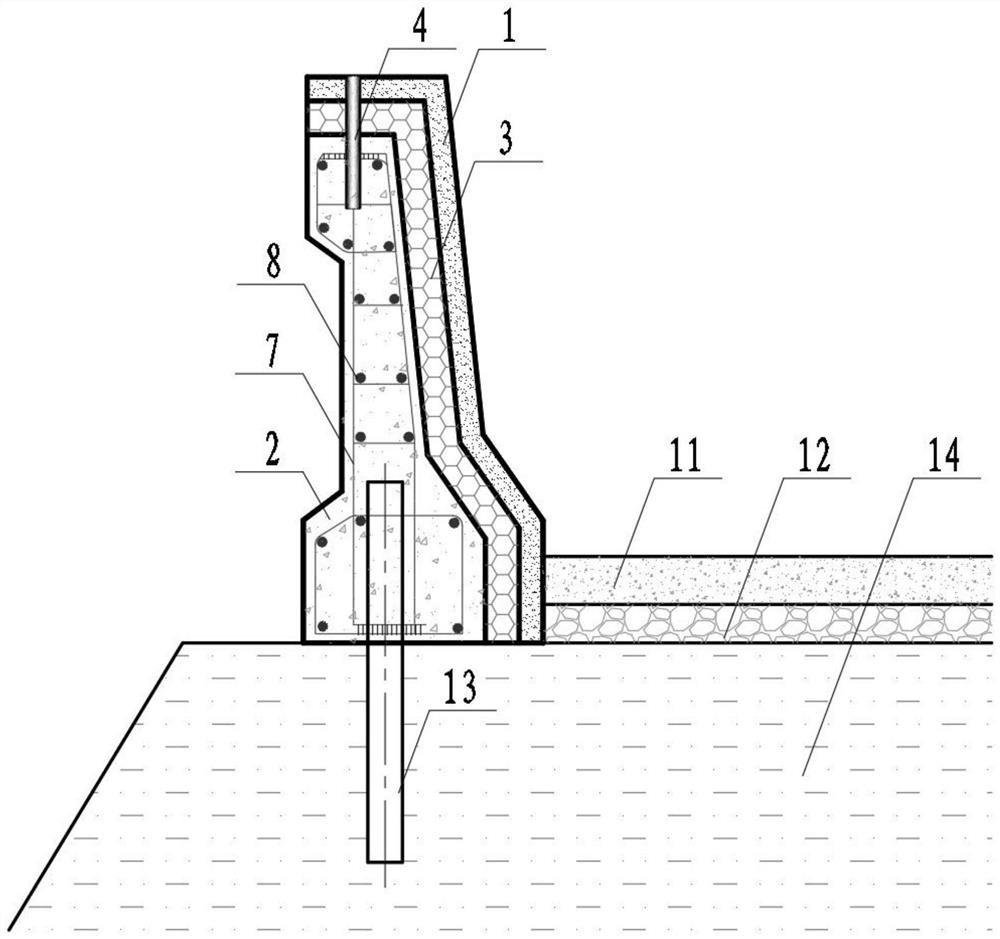

[0058] Such as figure 2 As shown, the functional gradient crash barrier of this embodiment includes a base 2, an energy dissipation layer 3, a UHPC panel 1 and an energy dissipation connector 4, and the energy dissipation layer 3 is arranged between the base 2 and the UHPC panel 1, and the base The seat 2, the energy dissipation layer 3 and the UHPC panel 1 are connected as a whole through the energy dissipation connector 4, and there are one or more energy dissipation connectors 4 (only one is shown in the figure).

[0059] In this embodiment, the guardrail is installed on the road of the soil roadbed 14, and steel pipe piles 13 required for connection with the base 2 are reserved on the soil roadbed 14.

[0060] In this embodiment, the energy-dissipating connector 4 runs through the UHPC panel 1 and the energy-dissipating layer 3 , and extends into the base 2 , and the position of the energy-dissipating connector 4 is set on the top of the guardrail.

[0061] In this embod...

Embodiment 3

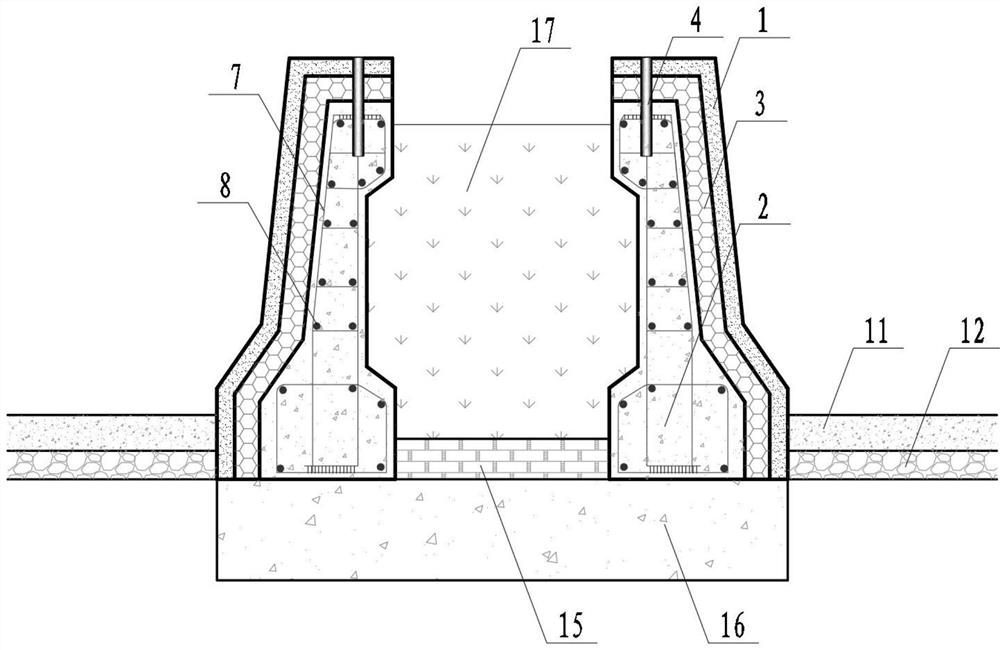

[0072] Such as image 3 As shown, the functional gradient crash barrier of this embodiment includes a base 2, an energy dissipation layer 3, a UHPC panel 1 and an energy dissipation connector 4, and the energy dissipation layer 3 is arranged between the base 2 and the UHPC panel 1, and the base The seat 2, the energy dissipation layer 3 and the UHPC panel 1 are connected as a whole through the energy dissipation connector 4, and there are one or more energy dissipation connectors 4 (only one is shown in the figure).

[0073] In this embodiment, the guardrail is installed on the separate central divider.

[0074] In this embodiment, the energy-dissipating connector 4 runs through the UHPC panel 1 and the energy-dissipating layer 3 , and extends into the base 2 , and the position of the energy-dissipating connector 4 is set on the top of the guardrail.

[0075] In this embodiment, the energy dissipation connector 4 is a metal rod or a metal tube.

[0076] In this embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com