Preparation method and application of photodynamic antiviral clothing finishing liquid

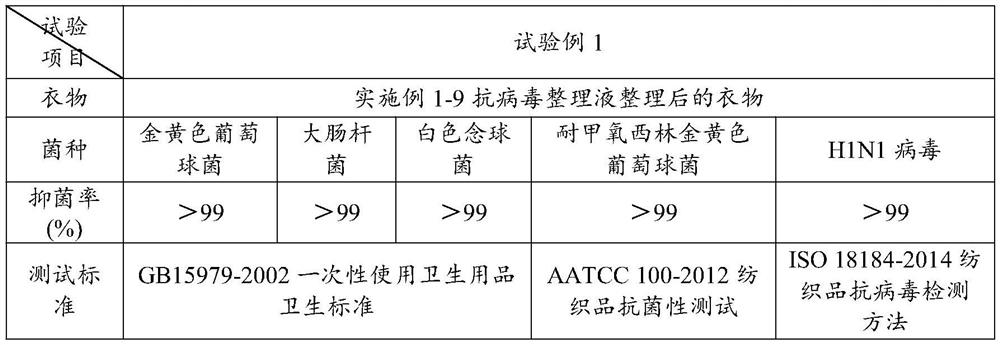

An anti-virus and finishing liquid technology, applied in fiber treatment, plant fiber, biochemical fiber treatment, etc., can solve problems such as cost increase, light source equipment structure, application range and field constraints, and restrictions on the development of photodynamic antibacterial, etc., to achieve easy operation , Easy to organize clothes, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

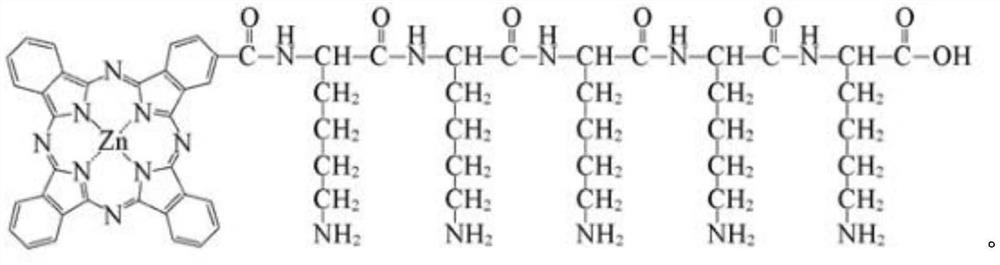

Method used

Image

Examples

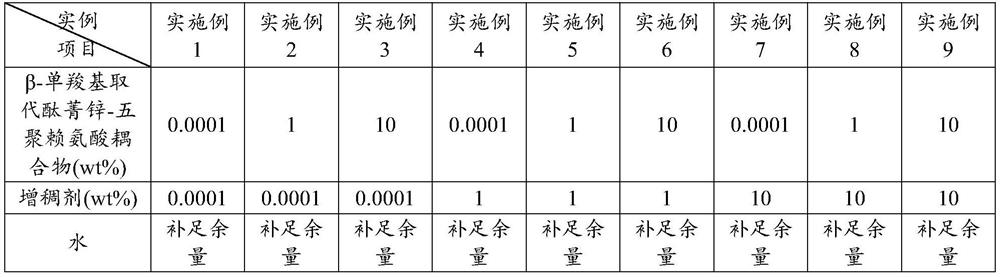

Embodiment 1

[0042] A kind of application method of photodynamic antiviral clothing finishing liquid, fabric is finished according to the following steps successively: (1) 0.0001% β-monocarboxyl substituted zinc phthalocyanine-penta-lysine coupler and 0.0001% thickening agent (castor oil / hydrogenated castor oil and ethylene oxide condensate) to compound into an antiviral system, add the remaining amount of water, dilute and mix evenly to obtain photodynamic antiviral clothing finishing liquid; (2) add 20ml clothing finishing liquid Add 4L of water to the solution and mix evenly; put 1kg of medical work clothes into it and soak for 5-8min to make it fully absorb the finishing solution; (3) wring it out and hang it in the air.

Embodiment 2

[0044] A kind of application method of photodynamic antiviral clothing finishing liquid, fabric is finished according to the following steps successively: (1) 1% β-monocarboxyl substituted zinc phthalocyanine-pentalysine coupler and 0.0001% thickening agent (polyoxyethylene dioleate) to form an antiviral system, add the remaining amount of water, dilute and mix well; (2) add 6L water to 30ml of clothing finishing liquid, mix well; put 1.5kg of personal clothes , Soak for 5-8 minutes to make it fully absorb the finishing solution; (3) Wring out the clothes and hang them in the air.

Embodiment 3

[0046] An application method of a photodynamic antiviral clothing finishing liquid, which comprises finishing the fabric according to the following steps: (1) 10% β-monocarboxyl substituted zinc phthalocyanine-penta-lysine coupling compound and 0.0001% thickening agent (polyoxyethylene lanolin ether) to form an antiviral system, add the rest of water, dilute and mix well; (2) add 5L water to 25ml clothing finishing liquid, mix well; put 1.5kg hotel linen , Soak for 5-8min to make it fully absorb the finishing solution; (3) Dry at 50-60°C after wringing out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com