Preparation method of polyaryletherketone resin

A polyaryletherketone and resin technology is applied in the field of preparation of polyaryletherketone resin, which can solve the problems of difficult characterization of polymer molecular weight, difficult control of process conditions, fast reaction rate, etc., and achieves reduced characterization difficulty and strong controllability. , molecular weight easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention provides a preparation method of polyaryletherketone resin, which comprises the following steps:

[0047] a) Under the action of an alkali catalyst, the dihalogen monomer of the structure represented by formula (i), the ketal diphenol monomer of the structure represented by formula (ii) and the copolymerized aromatic diphenol monomer of the structure represented by formula (iii) Carry out nucleophilic polycondensation in an organic solvent to obtain a ketal polymer of the structure represented by formula (I);

[0048] b) acidifying the ketal polymer in an acid solution to obtain a polyaryl ether ketone resin having a structure represented by formula (II);

[0049] X-Q-X formula (i); HO-R 3 -OH formula (iii);

[0050]

[0051] Wherein, Q is selected from one or more of the following substituents:

[0052]

[0053] X represents halogen, preferably -F or -Cl;

[0054] R 1 One or more of the following substituents:

[0055]

[0056] R 2 Selected from -CH 3 , -C 2 H 5 , ...

Embodiment 1

[0077] Choose The ketal bisphenol monomer (2,2-bis(4-hydroxyphenyl)-1,3-dioxolane) with m=1 and 4,4'-difluorobenzophenone were used for polycondensation to prepare polyarylene Ether ketone resin, the specific method is as follows:

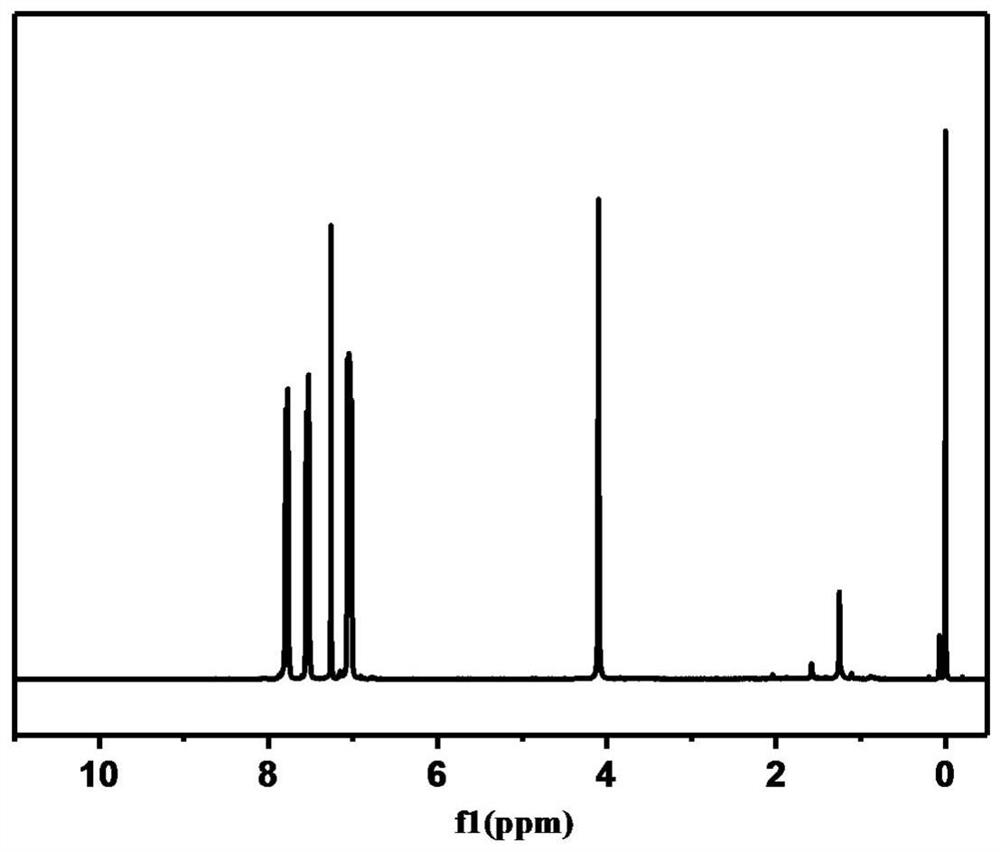

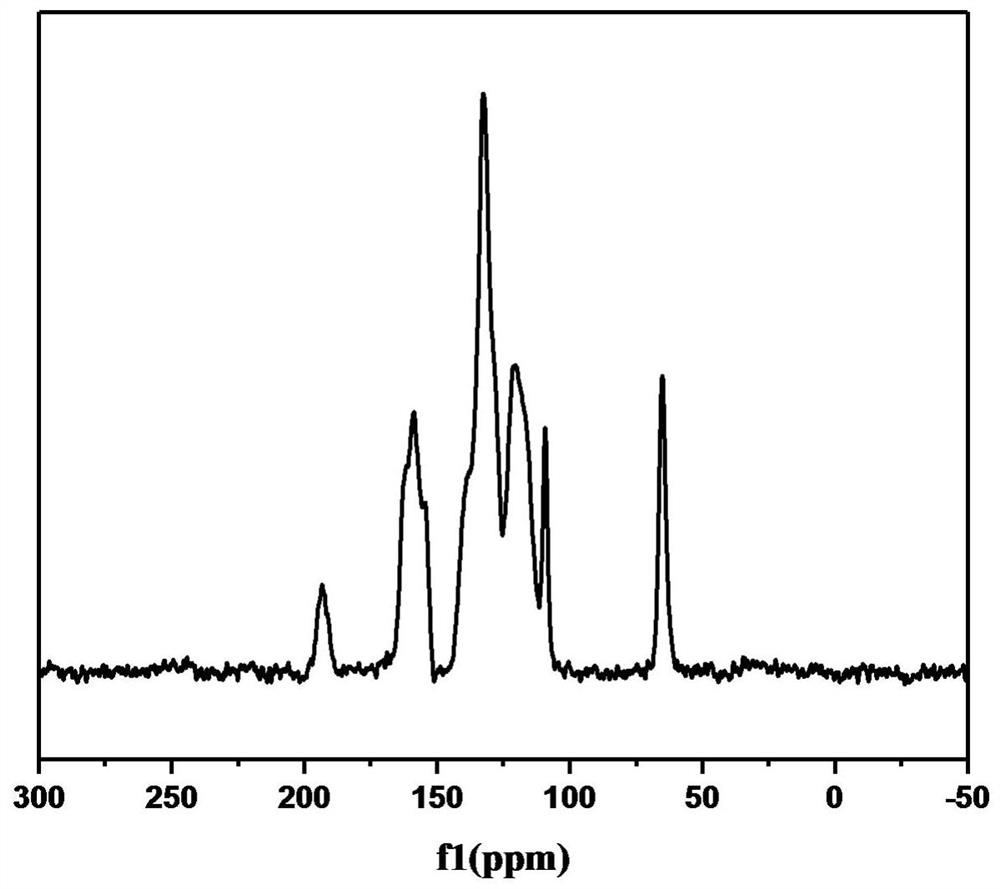

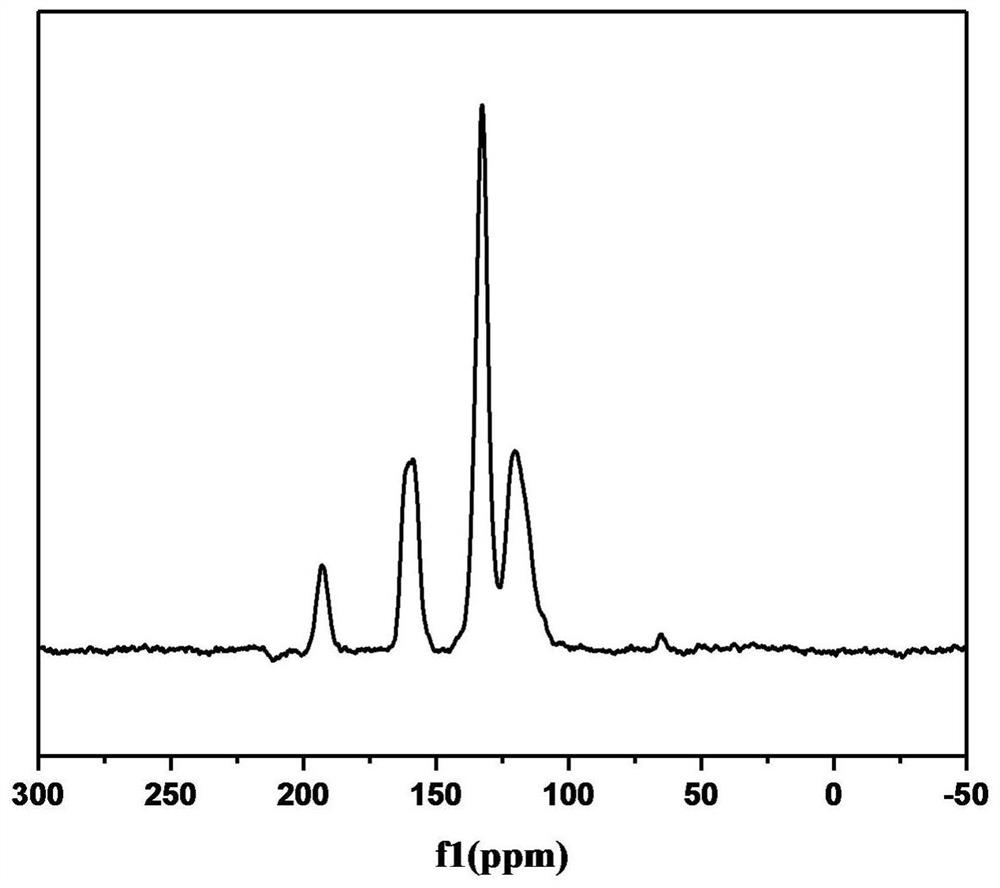

[0078] Mix 25.83g (0.1mol) 2,2-bis(4-hydroxyphenyl)-1,3-dioxolane, 21.82g (0.1mol) 4,4'-difluorobenzophenone and 28.9g( 0.21mol) potassium carbonate was added to a three-necked flask with nitrogen protection, mechanical stirring, water separator and condenser, then added 100mL dimethyl sulfoxide and 50mL toluene, heated to 150℃, toluene refluxed with water for 6h, distilled After toluene was heated to 180°C for nucleophilic polycondensation, 300mL dimethyl sulfoxide was added to dilute after polycondensation for 2 hours, and the supernatant was settled into deionized water after centrifugation to obtain the crude ketal polymer. Such as Figure 1~2 Shown.

[0079] The crude ketal polymer prepared above was crushed and then acidified by boiling in 2mo...

Embodiment 2

[0084] With reference to the preparation method of Example 1, the difference is only that the polycondensation time is extended from "2h" to "4h" to prepare the polyaryletherketone resin.

[0085] GPC test was performed on the polyaryl ether ketone resin prepared in this example, and the result showed that the weight average molecular weight of the polymer was about 38000 (corresponding to n=96).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com