Oil-containing and slag-containing wastewater treatment system

A wastewater treatment system and oil pollution technology, applied in the field of water treatment, can solve the problems of increased equipment complexity, construction cost and operation cost, poor effect of fine-grained iron oxide scale, and poor water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

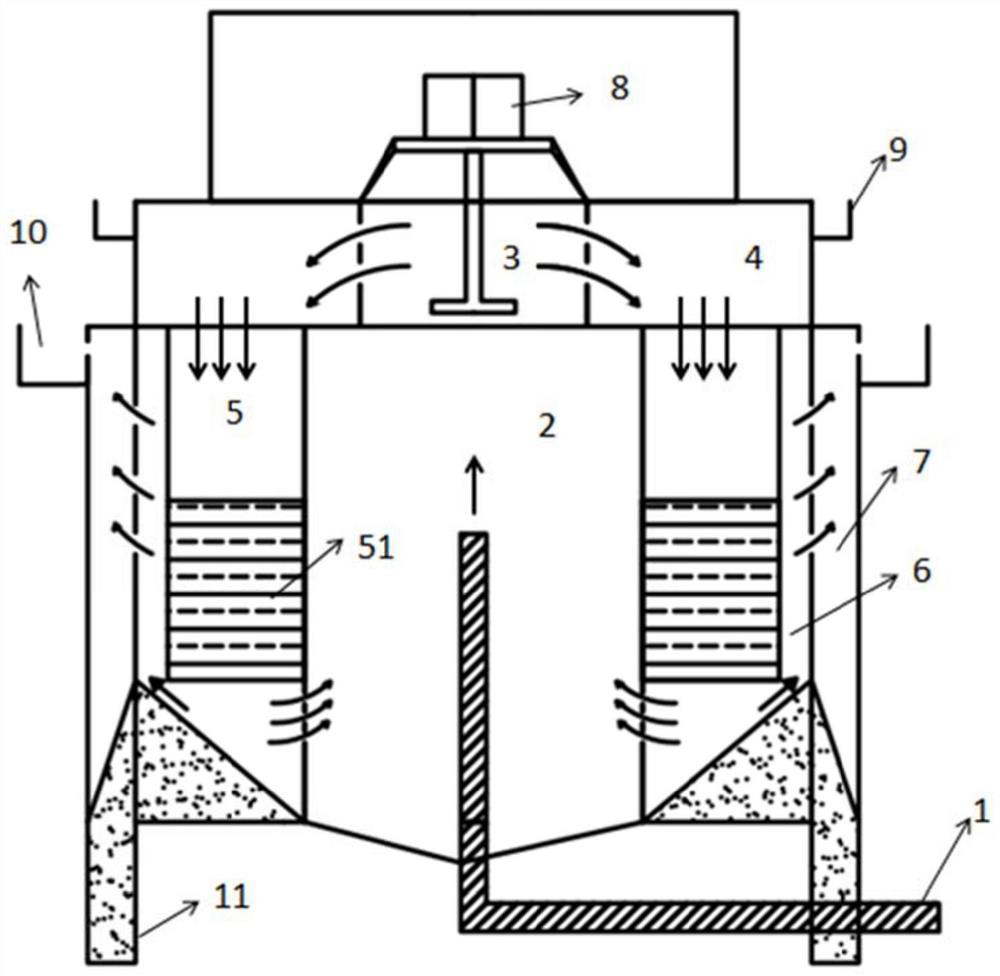

[0034] Using the oily and slag-containing wastewater treatment system of the present application, the wastewater enters the settling chamber 2 through the water inlet pipe 1, and during the rising process of the wastewater in the settling chamber, the bulk particulate matter settles to the bottom of the cone and is regularly discharged through the slag discharge port;

[0035] The wastewater after the large particles have settled enters the mixing chamber 3. Under the action of the aeration and stirring device in the mixing chamber, the wastewater enters the separation chamber 4, and the separated oil is discharged through the oil discharge port 9. In order to prevent the particles from being polluted by oil, the mixing chamber is opened 3. Ultrasonic devices installed at 4 places in the separation chamber;

[0036] The waste water in the separation chamber 4 flows down into the sinking chamber 5, and a sieve plate 51 is set in the sinking chamber to remove medium and small par...

Embodiment 2

[0039] The device of embodiment 1 is improved:

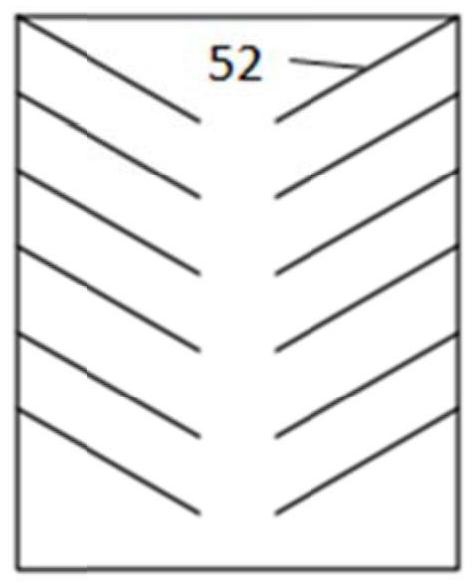

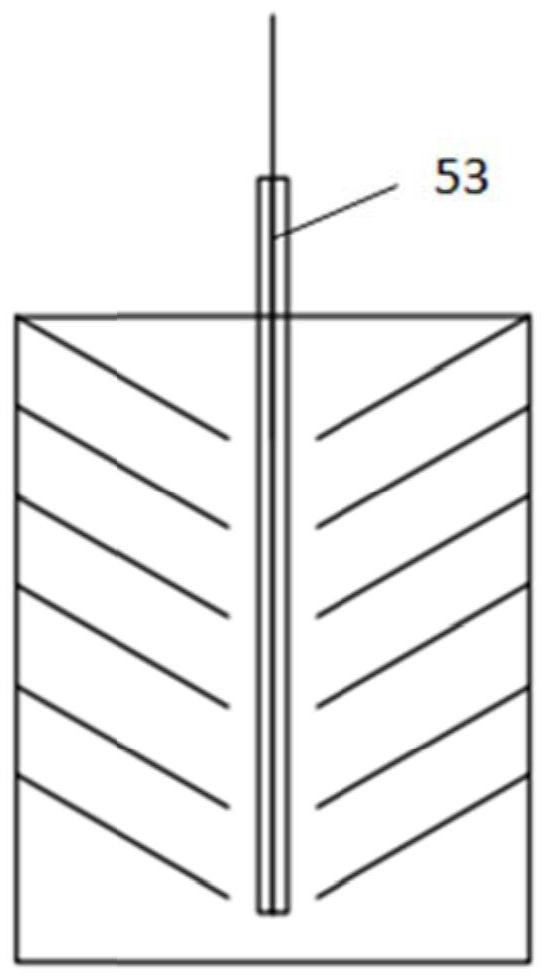

[0040] The sieve plate is an inverted cone structure, with the large mouth facing upwards and the small opening facing downwards. Both the large mouth and the small mouth are open. The electromagnet sieve plate 52 is intermittently energized. An electromagnet rod 53 is inserted at the stage structure, and the particles intercepted at the electromagnet sieve plate are attracted on the electromagnet rod 53, and then the electromagnet rod 53 is taken out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com