Grinding device for robot shell processing

A technology of robots and shells, which is applied in the direction of grinding drive devices, metal processing equipment, grinding machines, etc., can solve the operation requirements that are difficult to achieve large-scale rapid grinding, the grinding efficiency and grinding quality are not high, and it is difficult to achieve multiple Grinding of components and other issues to achieve the effect of improving the quality of grinding, improving the efficiency of grinding, and satisfying production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

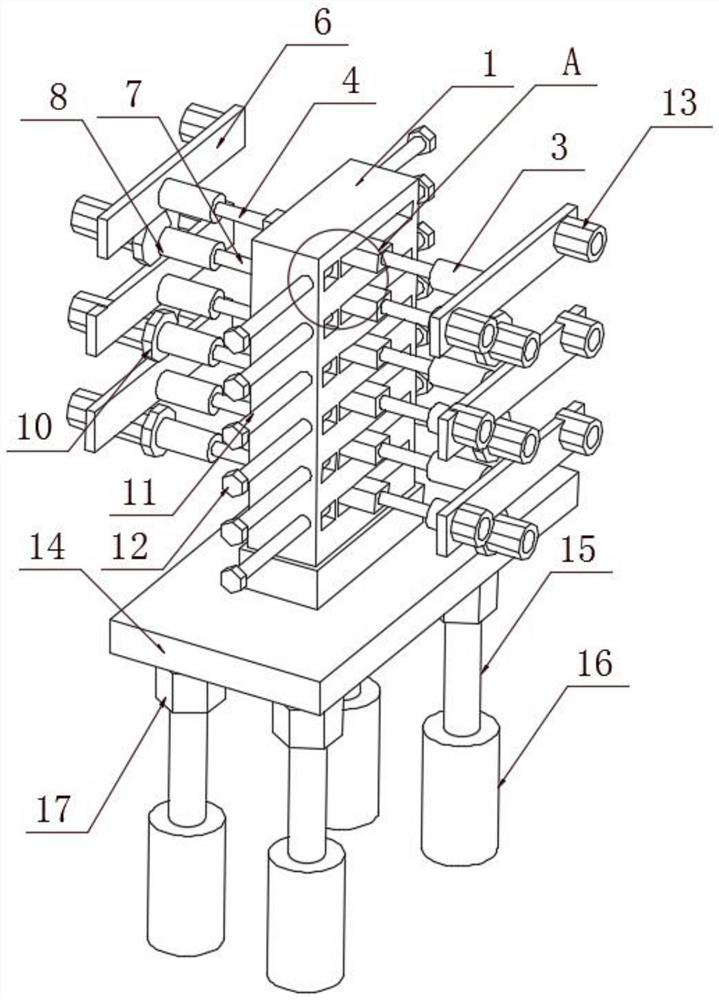

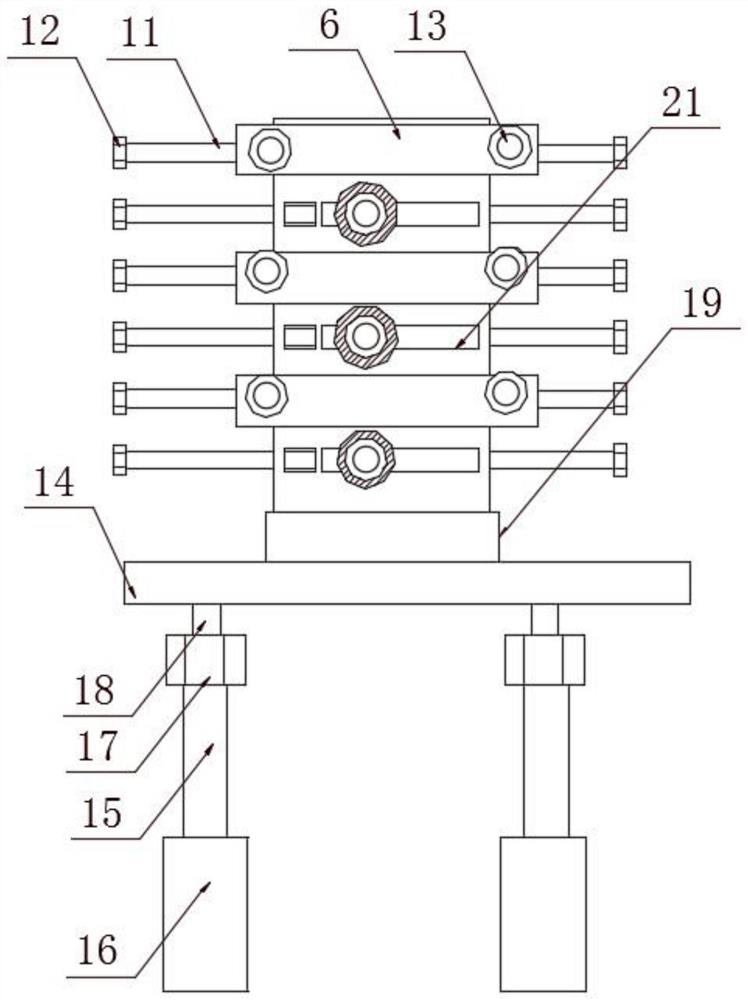

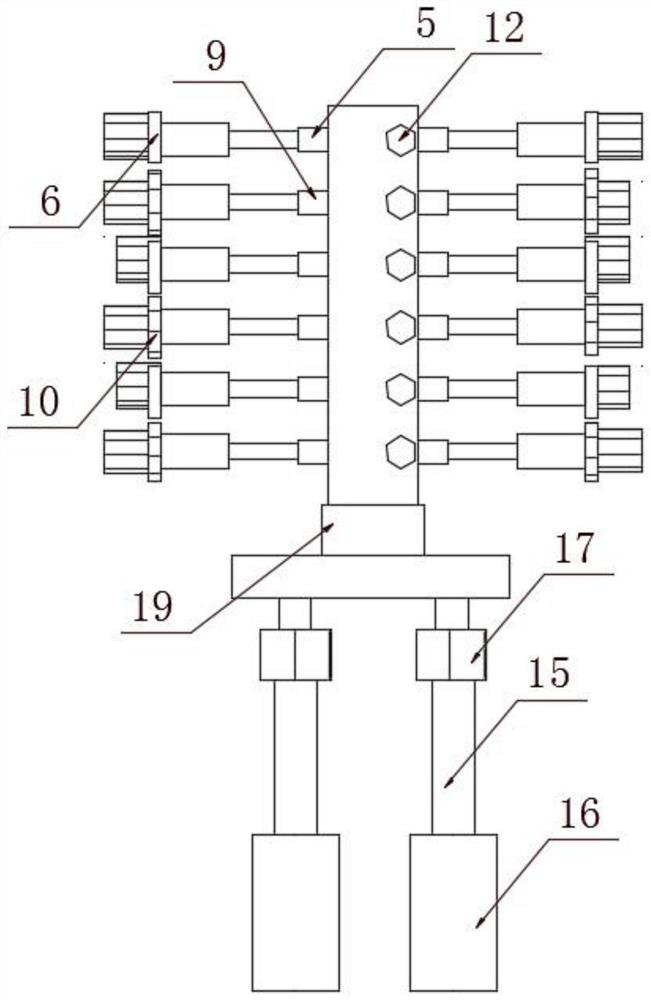

[0027] see Figure 1-8, in an embodiment of the present invention, a grinding device for robot shell processing includes a grinding installation box 1, a processing cover plate 14, a snap-in plate 22, and a support column 16, and the bottom surface of the grinding installation box 1 is sleeved with a sleeve positioning Groove plate 19, nested positioning groove plate 19 can be convenient to the installation and placement of grinding installation box body 1, and the bottom surface of nesting positioning groove plate 19 is welded with processing sleeve plate 14, and processing sleeve plate 14 plays the effect of integral connection, is convenient to The processing operation is carried out, the bottom surface of the processing cover plate 14 is welded with a sliding groove 20, the main function of the sliding groove 20 is to carry out the connection of the chute, the top surface of the support column 16 is provided with a telescopic column 15, and the telescopic column 15 The eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com