Tool for producing tiny parts

A technology of small parts and tooling, applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve problems such as not particularly ideal product accuracy, unfavorable large-scale mass production, and affecting work efficiency, etc., to achieve good clamping effect, clamping Easy and convenient to hold, improve the effect of clamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

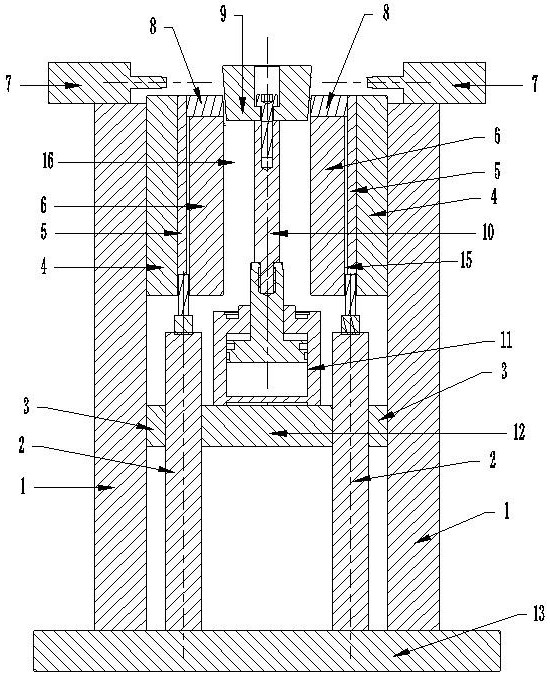

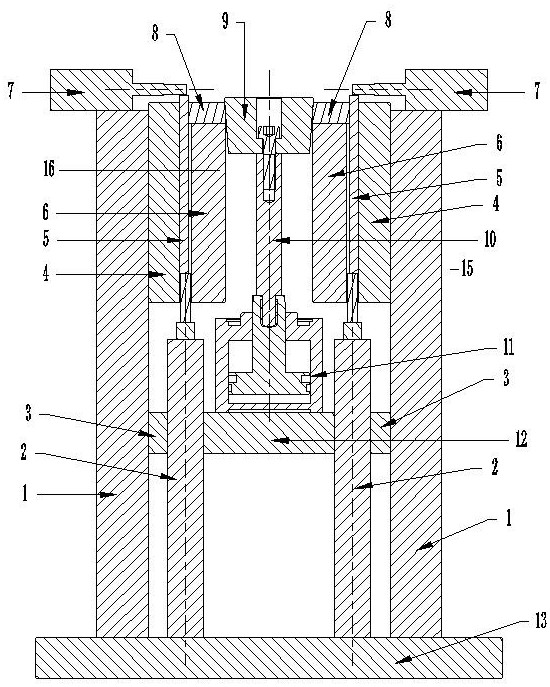

[0025] The present invention will be further described below in conjunction with the drawings, but the protection scope of the present invention is not limited to the following.

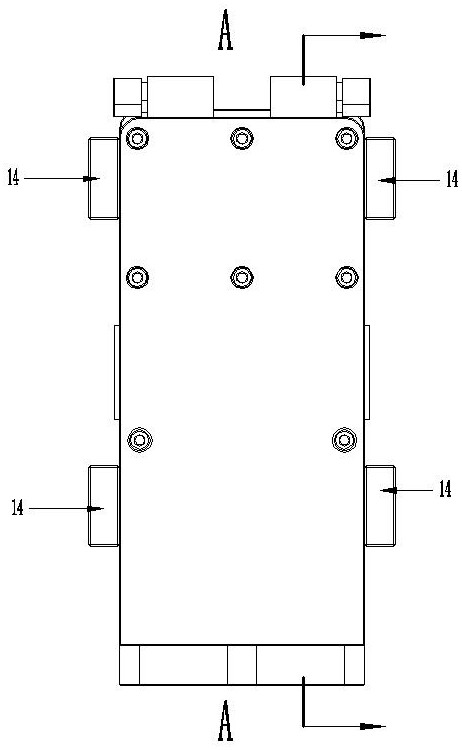

[0026] Such as Figure 1~Figure 3 As shown, a tool for producing small parts includes a frame 1, a guide seat 4, a slider seat 6, an ejection mechanism, a positioning mechanism and a clamping mechanism. Wherein, the frame 1 includes two vertical frames arranged symmetrically, the two vertical frames are strengthened and fixed by a plurality of fixing blocks 14, and the two vertical frames are arranged on the bottom plate 13.

[0027] A guide seat 4 is fixed at the opposite inner walls of the two vertical frames, and a slider seat 6 is provided on the opposite surface of the two guide seats 4, and each guide seat 4 and a slider seat 6 form a product placement groove 15, sliding The block base 6 is fixedly connected to the vertical frame through a fixed block 14.

[0028] In this solution, two product place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com