A kind of honeycomb structure diffusion brazing connection method

A honeycomb structure and connection method technology, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of difficult pressure control, poor profile accuracy, and low brazing strength in the diffusion brazing process, and achieve process pressure control. Difficulty, reduced corrosion, high welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

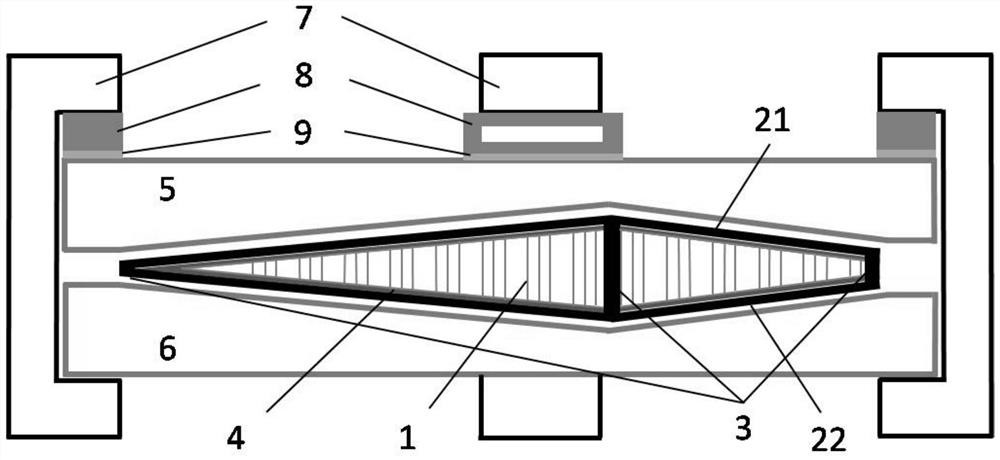

Embodiment 1

[0039] After the surface of the skin, skeleton and honeycomb core to be welded is polished and cleaned, a layer of 0.02mm thick intermediate layer is preset by the magnetron sputtering method, and the honeycomb core and the upper and lower two sets of skins are assembled. The height of the honeycomb core is larger than that of the surrounding skeleton. 0.01mm. After the assembly parts are put into the graphite mold, first place a 100Kg pressure block above the graphite mold. After the gap between the workpiece skin and the skeleton is controlled at 0.3mm, 8 groups of C-type graphite clamp blocks are evenly arranged around the tooling to clamp the graphite mold. , and place the return pad at the contact part between the clamping block and the mold. The remaining gap between the spacer and the mold is filled with metal gaskets to a tight fit. Put the assembled mold and workpiece in a vacuum furnace and vacuum to 10 -3 After the temperature rises to 30°C above the melting point...

Embodiment 2

[0041] After the surface of the skin, skeleton and honeycomb core to be welded is polished and cleaned, a layer of 0.03mm thick intermediate layer is preset by the magnetron sputtering method, and the honeycomb core and the upper and lower two sets of skins are assembled. The height of the honeycomb core is larger than that of the surrounding skeleton. 0.02mm. After the assembly parts are put into the graphite mold, first place a 200Kg pressure block above the graphite mold. After the gap between the workpiece skin and the skeleton is controlled at 0.2mm, 10 sets of C-type graphite clamping blocks are evenly arranged around the tooling to clamp the graphite mold. , and place the return pad at the contact part between the clamping block and the mold. The remaining gap between the spacer and the mold is filled with metal gaskets to a tight fit. Put the assembled mold and workpiece in a vacuum furnace and vacuum to 10 -3 After Pa, the heating is started. When the temperature ri...

Embodiment 3

[0043] After the surface of the skin, skeleton and honeycomb core to be welded is polished and cleaned, a layer of 0.04mm thick intermediate layer is preset by magnetron sputtering method, and the honeycomb core and the upper and lower two sets of skins are assembled. The height of the honeycomb core is larger than the surrounding skeleton. 0.03mm. After the assembly parts are put into the graphite mold, first place a 250Kg pressure block above the graphite mold. After the gap between the workpiece skin and the skeleton is controlled at 0.15mm, 10 sets of C-type graphite clamping blocks are evenly arranged around the tooling to clamp the graphite mold. , and place the return pad at the contact part between the clamping block and the mold. The remaining gap between the spacer and the mold is filled with metal gaskets to a tight fit. Put the assembled mold and workpiece in a vacuum furnace and vacuum to 10 -3 After Pa, the heating is started. When the temperature rises to 40°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com