Constructional engineering continuous steel bar cutting-off device

A technology for steel bar cutting and construction engineering, which is applied in the field of continuous steel bar cutting devices in construction engineering, can solve the problems of inability to realize continuous equidistant cutting of steel bars, poor continuity of cutting operation, etc., and achieve the effect of improving efficient cutting effect and continuous cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

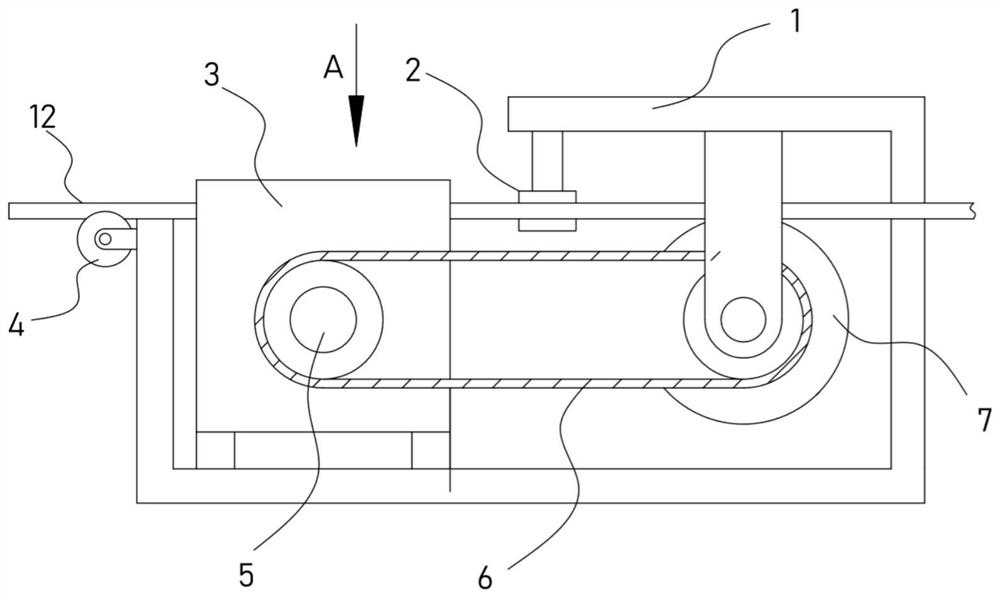

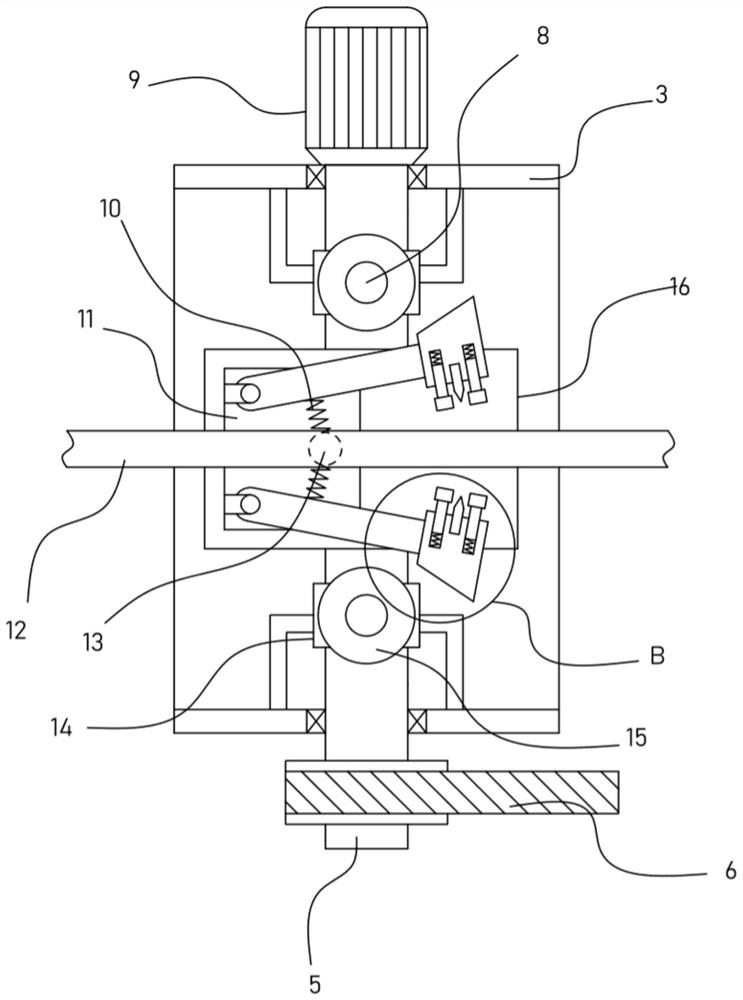

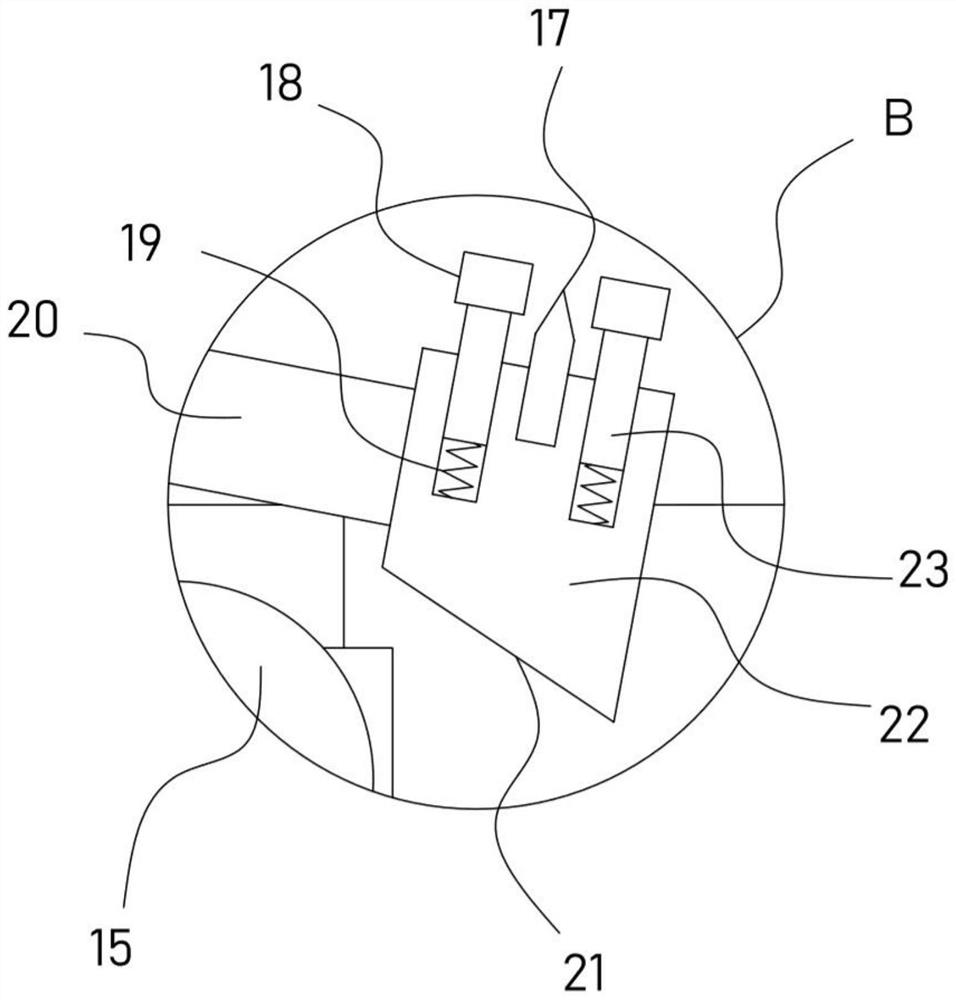

[0021] see Figure 1-3 , a continuous reinforcement cutting device for construction engineering, comprising a support frame 1, a fixed frame 3 is fixed on the support frame 1, a driving motor 9 is fixed on the fixed frame 3, and the output shaft of the driving motor 9 is coaxially fixed with a The drive shaft 5 in the fixed frame 3, the drive shaft 5 is sleeved with a rotating roller 16 fixed on the surface abutting the steel bar 12, the rotating roller 16 is provided with a groove 11, and two swing mechanisms are symmetrically arranged in the groove 11 , each swing mechanism is fixedly connected with a knife seat 22, and the knife seat 22 is provided with a cutting mechanism for cutting off the reinforcing bar 12.

[0022] When the steel bar 12 is cut off, the steel bar 12 is placed on the rotating roller 16, and the steel bar 12 is between the two swing mechanisms. The drive shaft 5 is driven to rotate by the drive motor 9 and then the rotating roller 16 is driven to rotate....

Embodiment 2

[0026] On the basis of Embodiment 1, in addition, the device is also provided with an elastic clamping mechanism including a sliding post 23 which is slidably embedded in the knife seat 22 and arranged parallel to the knife block 17. A telescopic spring 19 is fixed between them, and an arc plate 18 is fixed at the end of the sliding column 23 away from the knife seat 22 .

[0027] When the two swing rods 20 drive the knife block 22 close to the steel bar 12, the arc plate 18 on the knife block 22 contacts the steel bar 12 earlier than the knife block 17, and under the elastic resisting thrust of the telescopic spring 19, the two arc plates 18 first move The steel bar 12 is clamped and fixed, and then the telescopic spring 19 continues to compress, and the two knife blocks 17 will be cut off. The above operation ensures the short-term clamping and fixing effect of the steel bar 12 before cutting off, so that the cut-off position will not shift, effectively ensuring Cutoff mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com