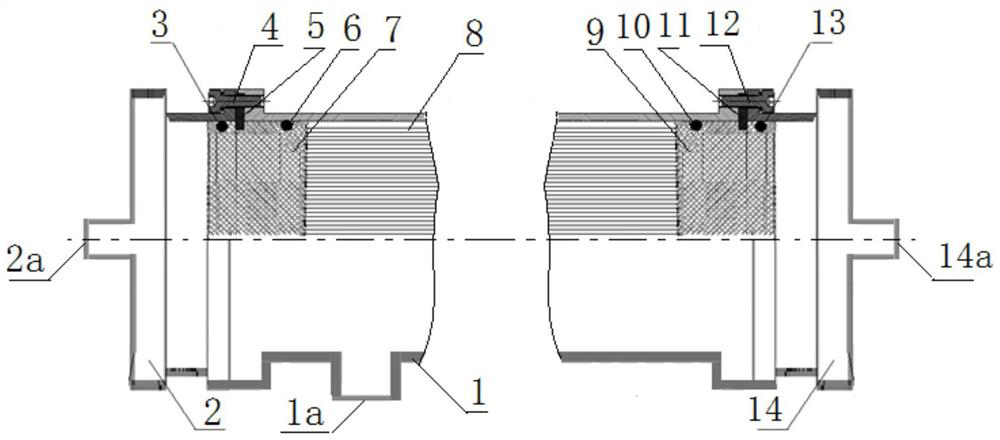

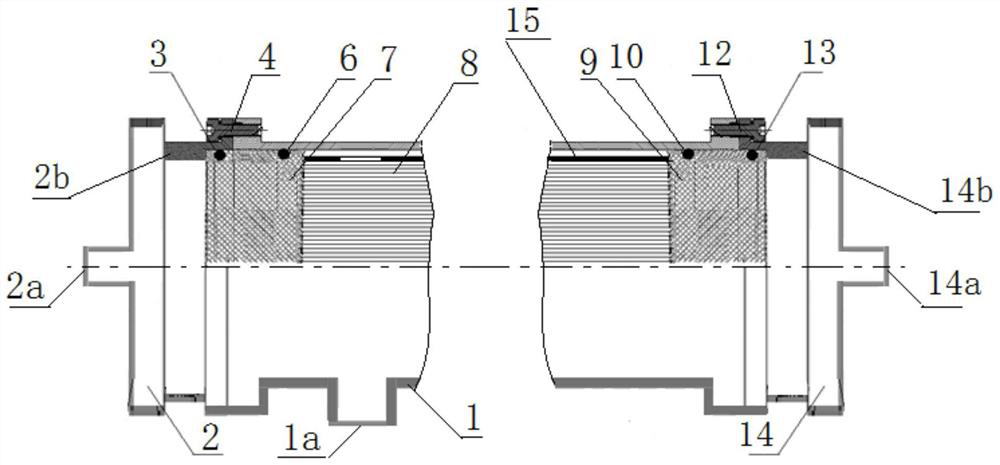

A membrane module structure of an air separator

An air separator and membrane module technology, applied in separation methods, semi-permeable membrane separation, and dispersed particle separation, can solve the problems of reduced nitrogen production efficiency, high oxygen concentration, and damage to the air tightness of the system, and achieve enhanced oxygen penetration The ability to reduce cracking probability and improve the efficiency of nitrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0011]In an embodiment 2 of the present invention, the membrane module is a cylinder, the external dimensions are: length 1.2 meters, and the maximum outer diameter of the end face circle is 200 mm. After adopting the present invention, the nitrogen production efficiency of the membrane module can be increased by more than 24% at room temperature. , The efficiency of nitrogen production is increased by more than 48% at a low temperature of -55°.

Embodiment 3

[0012] In an embodiment 3 of the present invention, the membrane module is a cylinder, the external dimensions are: length 1.5 meters, and the maximum outer diameter of the end face circle is 200 mm. After adopting the present invention, the nitrogen production efficiency of the membrane module can be increased by more than 30% at room temperature. , The efficiency of nitrogen production is increased by more than 60% at a low temperature of -55°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com