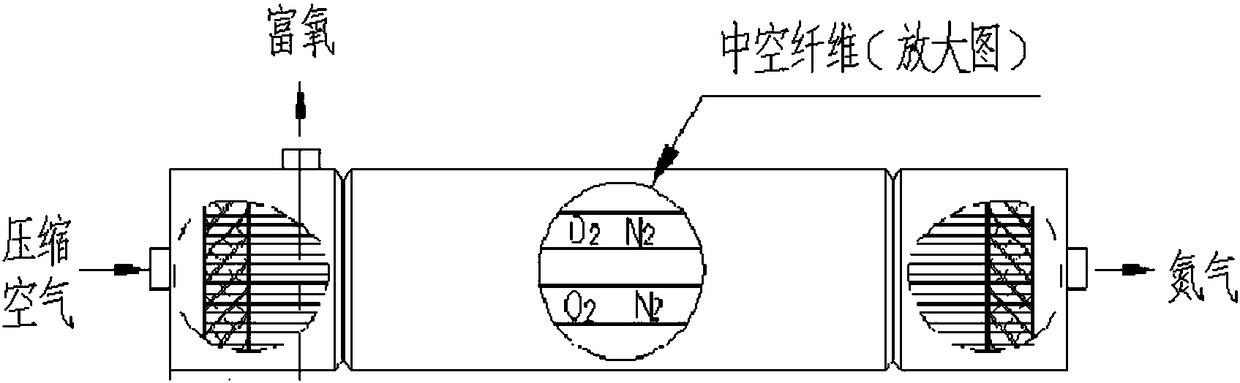

Testing device for optimizing comprehensive utilization effect of air separation membrane assembly

A testing device, air separation membrane technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of not considering the comprehensive use effect of parallel connection, not considering the cost, rough process, etc., to save resources and Cost, easy to expand, excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

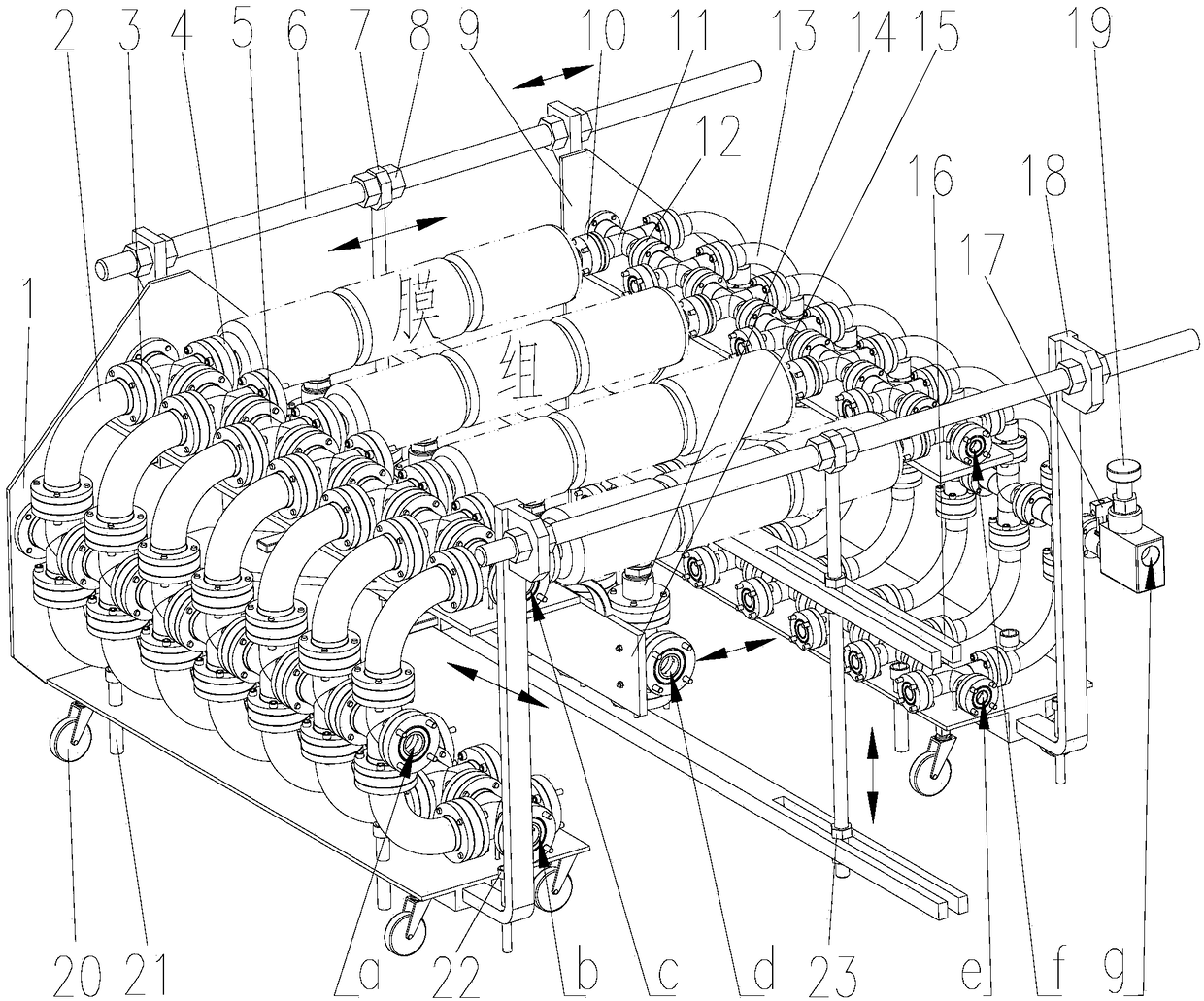

[0037] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

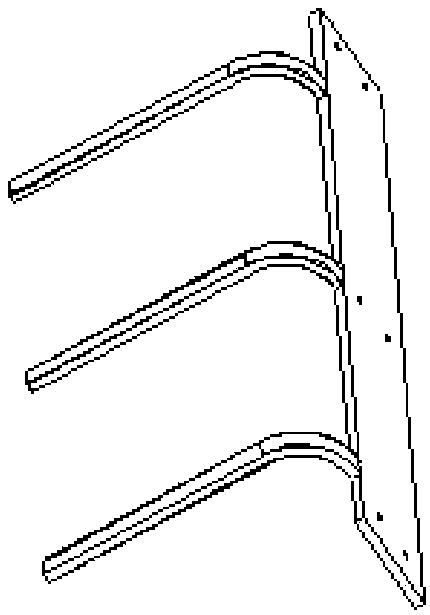

[0038] As attached Figure 2-3 As shown, a test device for optimizing the comprehensive use effect of air separation membrane modules of the present invention includes a left frame 1, multiple left elbow joints 2, multiple membrane group inlet flanges 4, and two smooth threaded rods 6. , Two membrane cushion adjustment rods 7, multiple fastening nuts one 8, right frame 9, multiple membrane group outlet flanges 10, multiple right bending joints 13, multiple oxygen-enriched flanges 14, sliding adjustment plate 15 , Two membrane pack pad rods 16, three interface joints 17, two sliding struts 18, flow regulating valves 19, universal wheels 20, threaded struts 21, threaded struts 22, and multiple fastening nuts 23 , Pipe a, pipe b, pipe c, pipe d, pipe e, pipe f and pipe g.

[0039] The left frame 1 includes a vertical plate, a horizontal bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com