High-purity nitrogen generator and its nitrogen-making process

A nitrogen generator and high-purity technology, applied in the direction of nitrogen purification/separation, can solve the problems of reduced nitrogen production efficiency, high noise, and low nitrogen purity, and achieve the effects of high nitrogen production efficiency, low noise, and improved adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

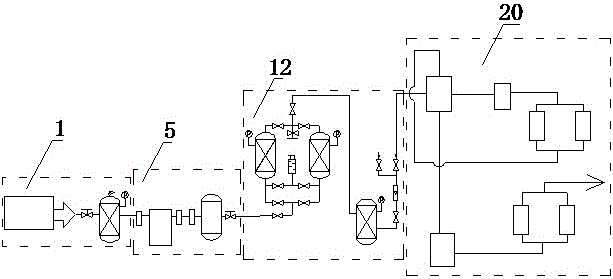

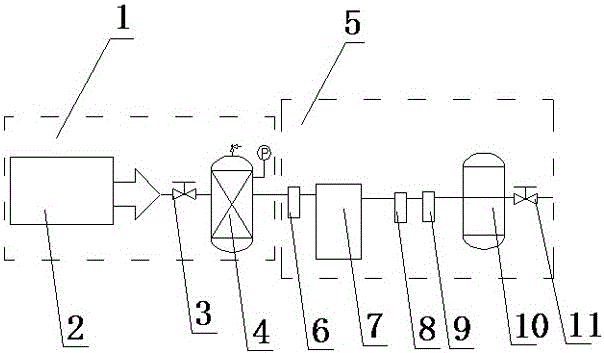

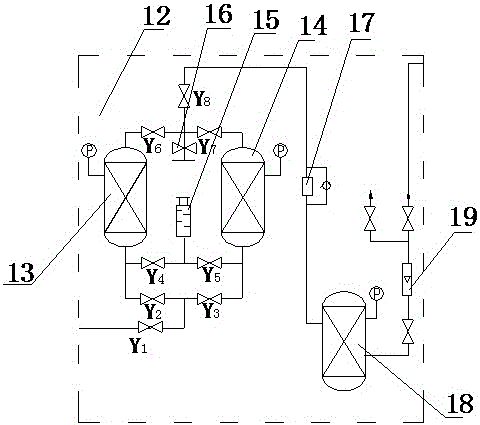

[0040] see Figure 1 to Figure 9 , the present invention relates to a high-purity nitrogen generator. The nitrogen generator includes an air compression system 1, an air purification system 5, a pressure swing adsorption nitrogen generation system 12 and a deoxygenation system 20 from front to back. In the air compression system 1 An air compressor 2 is provided. The air compressor 2 compresses the raw material air and enters the air storage tank 4 through the control of the ball valve 3. Most of the oil, liquid water, and dust in the raw material air are attached to the container wall and left at the bottom of the tank for regular storage. Discharge with the drain valve, and a part of air flow passes in the air cleaning system 5 from the air storage tank.

[0041] Described air purification system 5 is made up of C grade filter 6, freeze dryer 7, T grade filter 8, A grade filter 9 and air buffer tank 10, C grade filter 6, freeze dryer 7, T grade filter 8, A-level filter 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com