Oral implant

An implant and oral technology, applied in the field of oral implants, can solve problems such as affecting the efficiency of the operation, and achieve the effect of improving the efficiency of the operation and reducing the operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

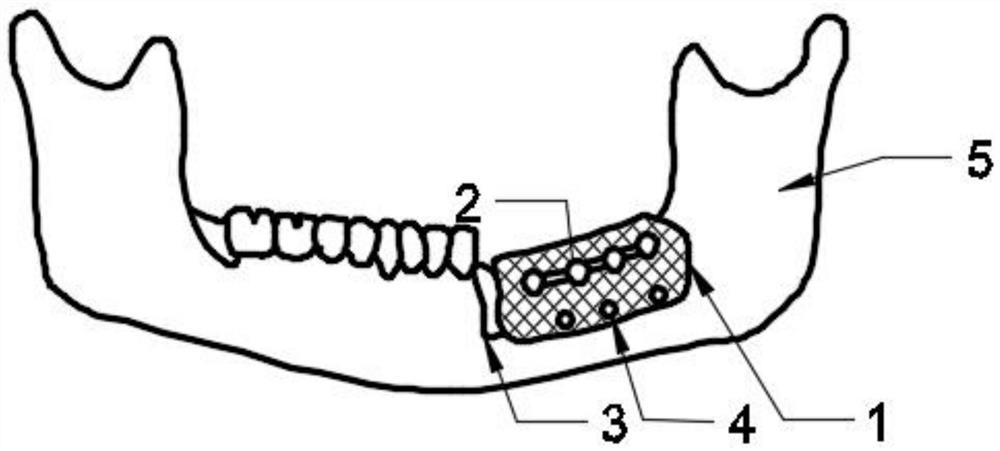

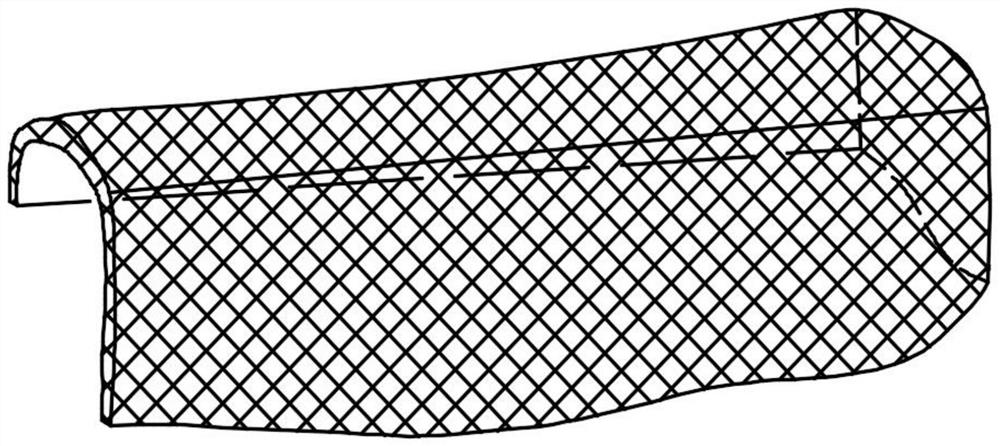

[0027] Please refer to the attached Figure 1-2 , the purpose of this embodiment is to provide an oral implant, including: a porous tantalum body 1 obtained by mirroring the healthy side with respect to the midline, holes are added on the surface of the porous tantalum body 1 to reduce weight, and the porous tantalum body 1 is made of tantalum metal 3D printing, preferably, the length of the porous tantalum body 1 is 20 mm, and the thickness of the porous tantalum body 1 is 0.5 mm. It should be pointed out that tantalum metal is known as "biophilic metal", with excellent biocompatibility, biological inertness, excellent corrosion resistance, stable chemical properties, no inflammatory reaction with tissue and body fluids, and long-term effective in the human environment. The existence of; excellent mechanical properties, high hardness, friction and wear resistance. The modulus of elasticity of tantalum is very similar to that of human bone, thus effectively avoiding the pheno...

Embodiment 2

[0032] Please refer to the attached Figure 1-2 , the purpose of this embodiment is to provide an oral implant, including: a porous tantalum body 1 obtained by mirroring the healthy side with respect to the midline, holes are added on the surface of the porous tantalum body 1 to reduce weight, and the porous tantalum body 1 is made of tantalum metal 3D printing, preferably, the length of the porous tantalum body 1 is 140 mm, and the thickness of the porous tantalum body 1 is 1 mm. It should be pointed out that tantalum metal is known as "biophilic metal", with excellent biocompatibility, biological inertness, excellent corrosion resistance, stable chemical properties, no inflammatory reaction with tissue and body fluids, and long-term effective in the human environment. The existence of; excellent mechanical properties, high hardness, friction and wear resistance. The modulus of elasticity of tantalum is very similar to that of human bone, thus effectively avoiding the phenom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com