Coating method of lithium battery diaphragm, lithium battery diaphragm and lithium battery

A diaphragm and coating technology, which is applied in the direction of secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve the problems of high voltage resistance, poor stability of lithium battery diaphragms, etc., and achieve improved energy density and small shrinkage , the effect of small value-added ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

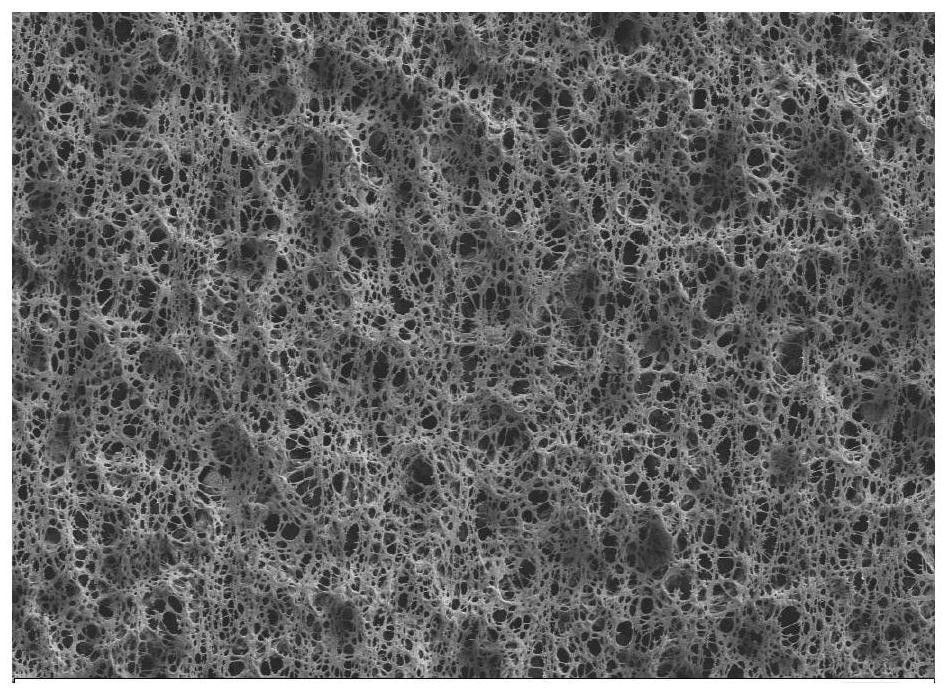

Image

Examples

Embodiment 1

[0038] A coating method for a lithium battery diaphragm, comprising the following steps:

[0039] Step 1, prepare coating slurry: weigh a certain amount of polyvinylidene fluoride and dissolve it in an organic solvent, add a binder to disperse evenly, and then add a pore-forming agent to disperse evenly; specifically, mix 18 parts of polyvinylidene fluoride with 47 Parts of acetone are mixed uniformly in proportion to obtain mixed slurry A; 4 parts of polyvinyl alcohol are added to mixed slurry A to obtain mixed slurry B; then 7 parts of ethylene carbonate are added to mixed slurry B to obtain mixed slurry Material C is the coating slurry.

[0040] Step 2, apply the coating slurry evenly on the surface of the base film to obtain a coated diaphragm; specifically, place the uniformly mixed coating slurry on the coating head, feed it with a peristaltic pump, and use a gravure roller to coat evenly Coated on the surface of the base film, and continuously coated at a speed of 45m / ...

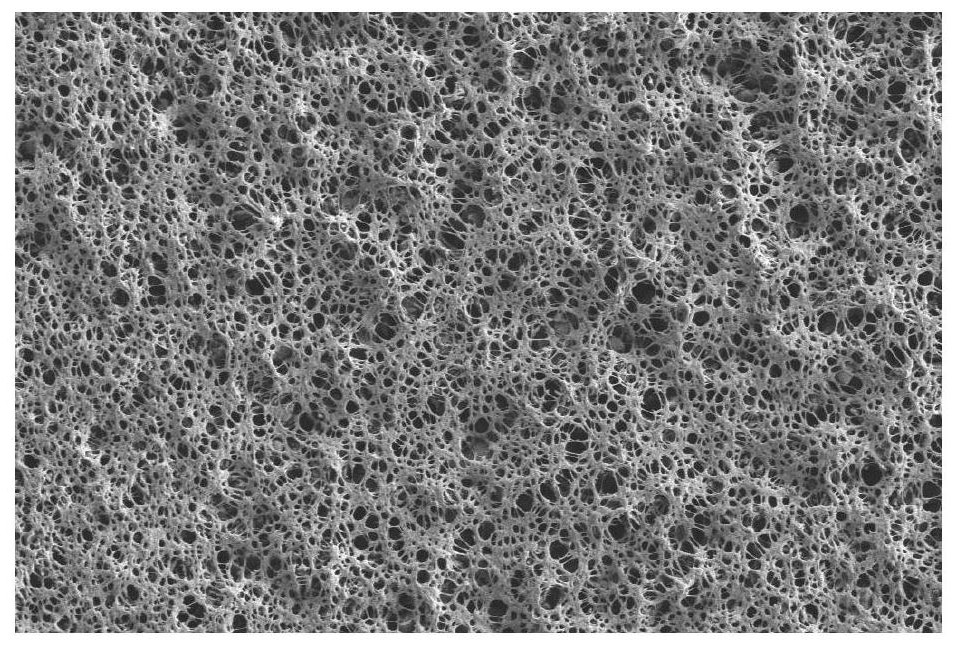

Embodiment 2

[0047] A coating method for a lithium battery diaphragm, comprising the following steps:

[0048] Step 1, preparation of coating slurry: weigh a certain amount of aromatic fiber and dissolve it in an organic solvent, add a binder to disperse evenly, and then add a pore-forming agent to disperse evenly; specifically, mix 14 parts of aromatic fiber with 53 Parts of N,N-dimethylformamide are mixed uniformly in proportion to obtain mixed slurry A; 3 parts of polyvinylpyrrolidone are added to mixed slurry A to obtain mixed slurry B; then 5 parts of ethylene carbonate are added to the mixed slurry In the slurry B, the mixed slurry C, that is, the coating slurry was obtained.

[0049] Step 2, apply the coating slurry evenly on the surface of the base film to obtain a coated diaphragm; specifically, place the uniformly mixed coating slurry on the coating head, feed it with a peristaltic pump, and use a dip coating method to uniformly Coated on the surface of the base film, and contin...

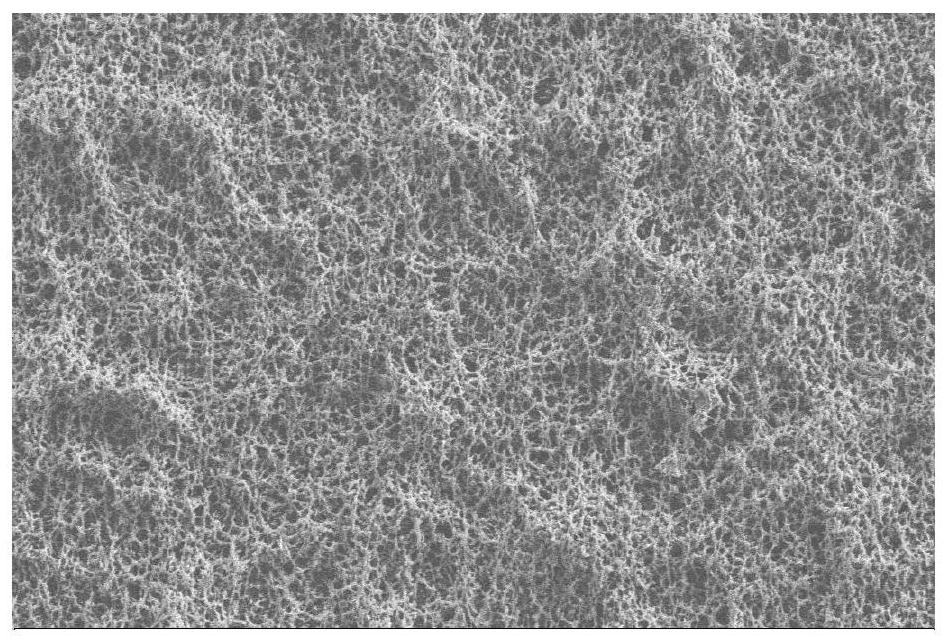

Embodiment 3

[0056] A coating method for a lithium battery diaphragm, comprising the following steps:

[0057] Step 1, prepare the coating slurry: weigh a certain amount of imide fiber and dissolve it in an organic solvent, add a binder to disperse evenly, and then add a pore-forming agent to disperse evenly; specifically, 14 parts of polyimide fiber Mix with 53 parts of N,N-dimethylformamide in proportion to obtain mixed slurry A; add 3 parts of polyvinylpyrrolidone to mixed slurry A to obtain mixed slurry B; then add 5 parts of ethylene carbonate into the mixed slurry B to obtain the mixed slurry C, that is, the coating slurry.

[0058] Step 2, apply the coating slurry evenly on the surface of the base film to obtain a coated diaphragm; specifically, place the uniformly mixed coating slurry on the coating head, feed it with a peristaltic pump, and use a dip coating method to uniformly Coated on the surface of the base film, and continuously coated at a speed of 50m / min.

[0059] Step 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com