Quay crane fault monitoring method based on multi-signal fusion and Adam optimization algorithm

An optimization algorithm and fault monitoring technology, applied in the field of quay crane condition prediction and quay crane fault monitoring, can solve the problems of overfitting, complex model, large model calculation amount, etc., to achieve reliable prediction, improve accuracy, and high prediction accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

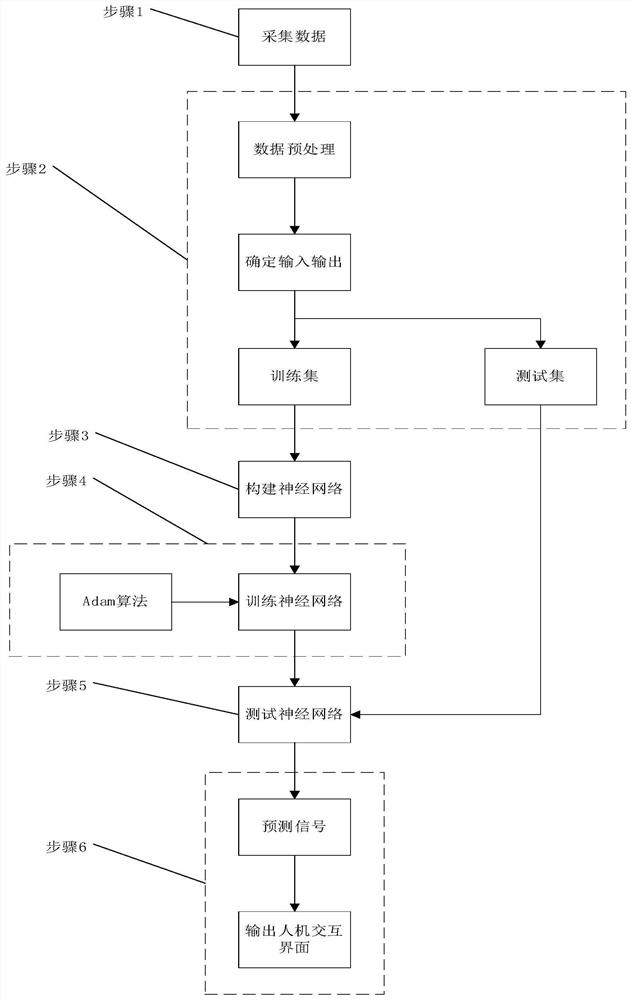

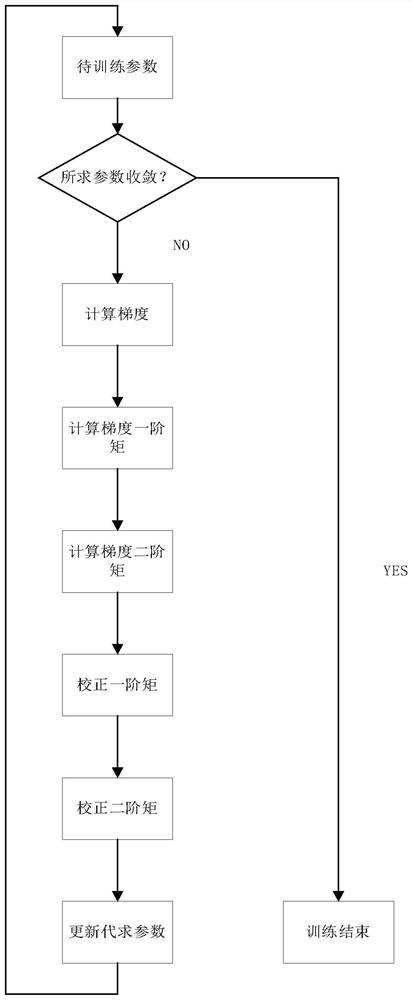

[0025] A kind of quay crane fault monitoring method based on multi-signal fusion and Adam optimization algorithm of the present invention, see figure 1 shown, including the following process:

[0026] Step 1, collect data;

[0027] Due to the large size of the quay crane, it is only necessary to select special and representative measuring points to monitor the entire quay crane mechanism and structure. Taking the vibration signal, stress signal and temperature signal as an example, since the vibration and temperature changes of the girder, the main motor, and the traction motor of the trolley are the most obvious during the operation, the data collection point is determined here, and the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com