Fused cone type long-period fiber bragg grating, preparation device, preparation method and laser system

A fiber grating and preparation device technology, which is applied in the direction of lasers, cladding fibers, grating fibers, etc., can solve the problems of small bandwidth, large fiber size, and preparation of long-period fiber gratings, and achieve improved stimulated Raman scattering and insertion loss Small, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] figure 1 It is a structural schematic diagram of a fusion-tapered long-period fiber grating in Embodiment 1; a fusion-tapered long-period fiber grating includes an optical fiber, and the optical fiber is provided with more than one tapered region 9, and the distance between each tapered region 9 is equal, the The pitch is the period of the fused-tapered long-period fiber grating, and the tapered region 9 is formed by fused tapering. The optical fiber is a large mode field double-clad optical fiber.

Embodiment 2

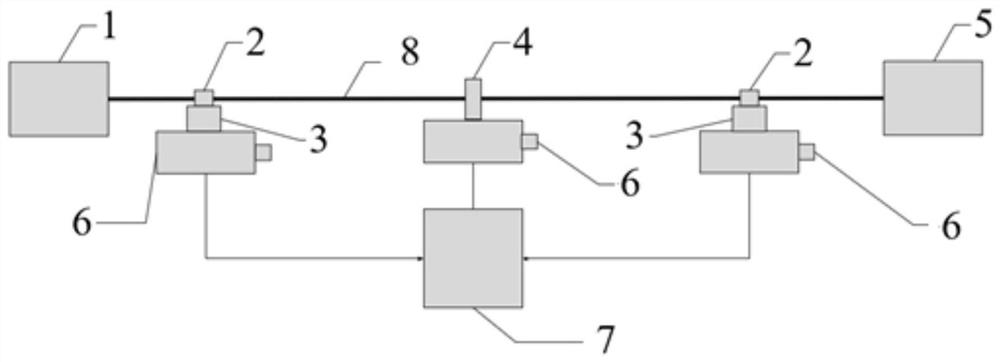

[0054] figure 2 It is a schematic structural diagram of the preparation device of the fusion-tapered long-period fiber grating in Example 2. A preparation device for a fusion-tapered long-period fiber grating includes an optical fiber fixture 2, an optical fiber heating element 4, a three-dimensional adjustment frame 3, an electric displacement platform 6 and a computer 7. There are two optical fiber clamps 2, which are the left optical fiber clamp and the right optical fiber clamp; there are two three-dimensional adjustment frames 3, which are the left three-dimensional adjustment frame and the right three-dimensional adjustment frame. In this embodiment, the three-dimensional adjustment base 3 for manual adjustment. There are three electric displacement platforms 6, which are respectively a left electric displacement platform, a middle electric displacement platform and a right electric displacement platform. The left three-dimensional adjustment frame and the right three...

Embodiment 3

[0057] Utilizing the preparation device of the fusion-tapered long-period fiber grating provided in Example 2, this embodiment provides a preparation method of the fusion-tapered long-period fiber grating, comprising the following steps:

[0058] (1) Cut the optical fiber 8 with a suitable length, coat the area of the optical fiber 8 to be prepared with a fused tapered long-period fiber grating with a chemical stripper, and then wipe the two ends of the optical fiber through the left optical fiber clamp and the right optical fiber clamp after wiping with alcohol. The optical fiber clamp is clamped, and the two three-dimensional adjustment frames and the left and right electric displacement platforms are adjusted to ensure the level of the optical fiber 8 between the two optical fiber clamps;

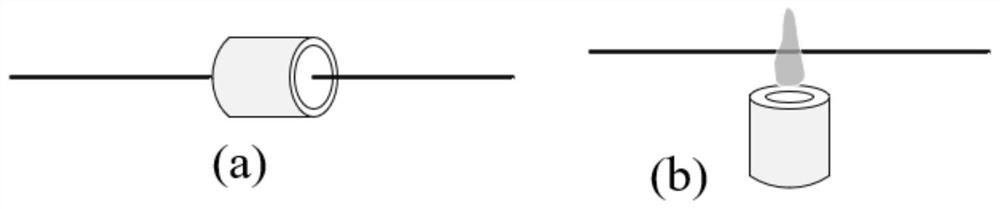

[0059] (2) Adjust the position of the optical fiber heating element 4 through the middle electric displacement platform. The optical fiber heating element 4 uses a flame to heat the are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com