R-test precision ball head detection device and calibration method thereof

A detection device and calibration method technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of positioning error, processing error, detection and calibration error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

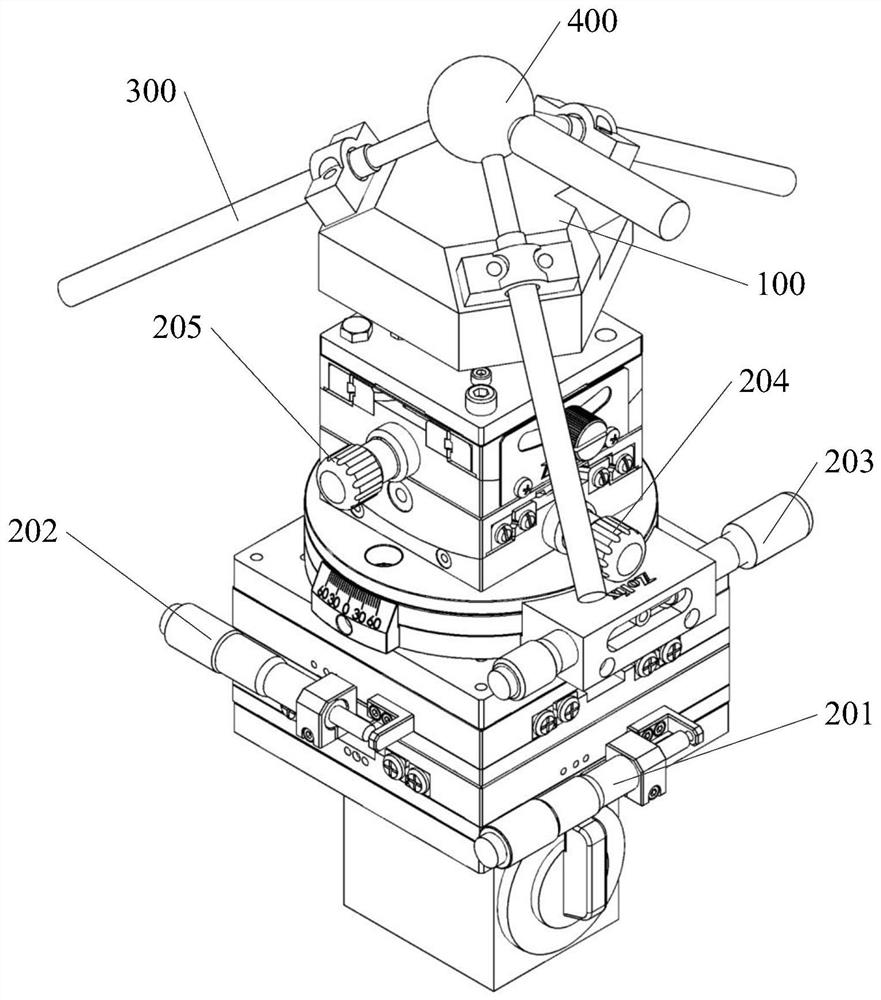

[0031] This embodiment provides a mounting base 100, the mounting base 100 is fixed on the five-dimensional manual sliding table, and the corresponding sensor and R-test ball head 400 are matched and installed, and then equipped with the corresponding software algorithm to realize the multi-axis linkage accuracy detection of the machine tool and calibration.

[0032] The mounting seat 100 described in this embodiment is provided with a mounting surface 101, a reference surface A102, a reference surface B103 and a fixing surface 104, and its structure is as follows figure 1 shown. There are three installation surfaces 101, and the three installation surfaces 101 are evenly distributed on the same ring with the axis of the installation seat 100 as the center of the circle, and the installation surfaces 101 are all inclined to the center of the circle, and the distance between the three installation surfaces 101 and the horizontal plane The included angles between them are equal...

Embodiment 2

[0036] This embodiment provides an R-test detector, which includes a five-dimensional manual slide table, a displacement sensor 300, an R-test ball head 400 and the mounting seat 100 provided in Embodiment 1. Its structure is as follows figure 2 shown. The five-dimensional manual sliding table adopts the high-precision sliding table series developed by Zhuoli Hanguang. The main material is made of 2024 aluminum alloy material, and its surface is oxidized black, with high strength, good wear resistance and beautiful appearance. The five-dimensional manual slide table described in this embodiment includes two mutually perpendicular linear slide table A202 and linear slide table B201, a rotary slide table 203, and two mutually perpendicular swing slide table A204 and swing slide table B205; The linear slide table A202, the linear slide table B201, the rotary slide table 203, the swing slide table A204 and the swing slide table B205 are arranged in sequence from bottom to top, an...

Embodiment 3

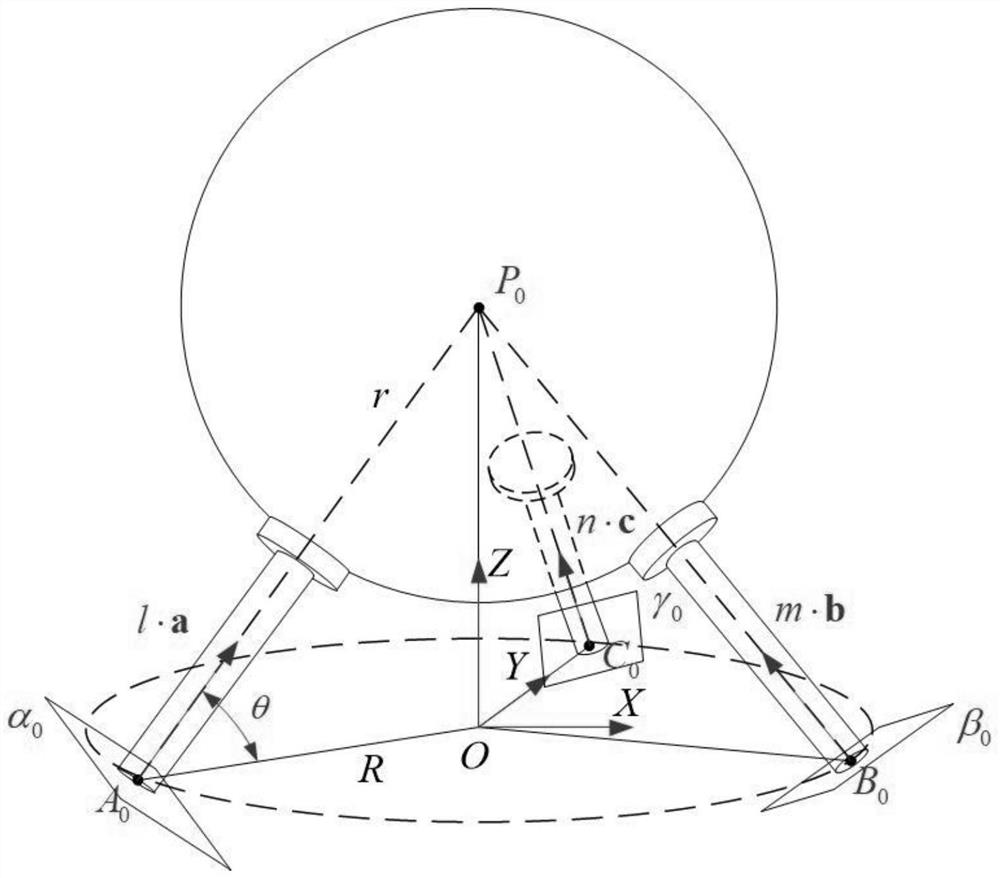

[0038] This embodiment provides a method for calibrating the R-test precision ball head detection device, which is used to calibrate the positioning error between the R-test precision ball head detection device and the processing machine tool. The R-test precision ball head detection device The calibration method includes the following steps:

[0039](1) The R-test precision ball detection device described in embodiment 2 is installed on the worktable of the processing machine tool through the magnetic suction base, and the R-test precision ball detection device is adjusted during installation so that the reference plane A102 is in line with the processing machine tool The coordinates XOY are parallel, and the reference plane B103 is parallel to the coordinates XOZ of the processing machine tool. At this time, the parallelism is roughly parallel through the naked eye observation of the staff, and the precise parallelism required by the processing has not been realized. The prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com