Spring push rod mechanism, rapid connection device and anti-loose method

A spring push rod and rod head technology, applied in the direction of pivot connection, connecting rod, shaft installation, etc., can solve problems such as loosening and detachment, bending deformation of mandrel and joint bearing, potential safety hazards, etc., to avoid loosening and detachment, avoid bending Effects of deformation and improvement of industrial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

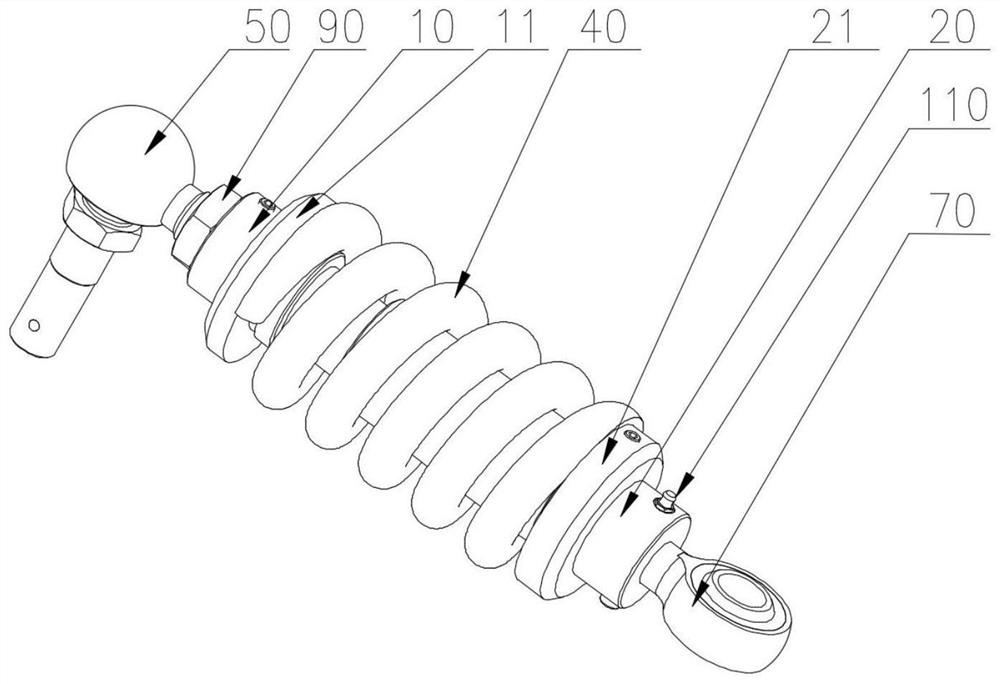

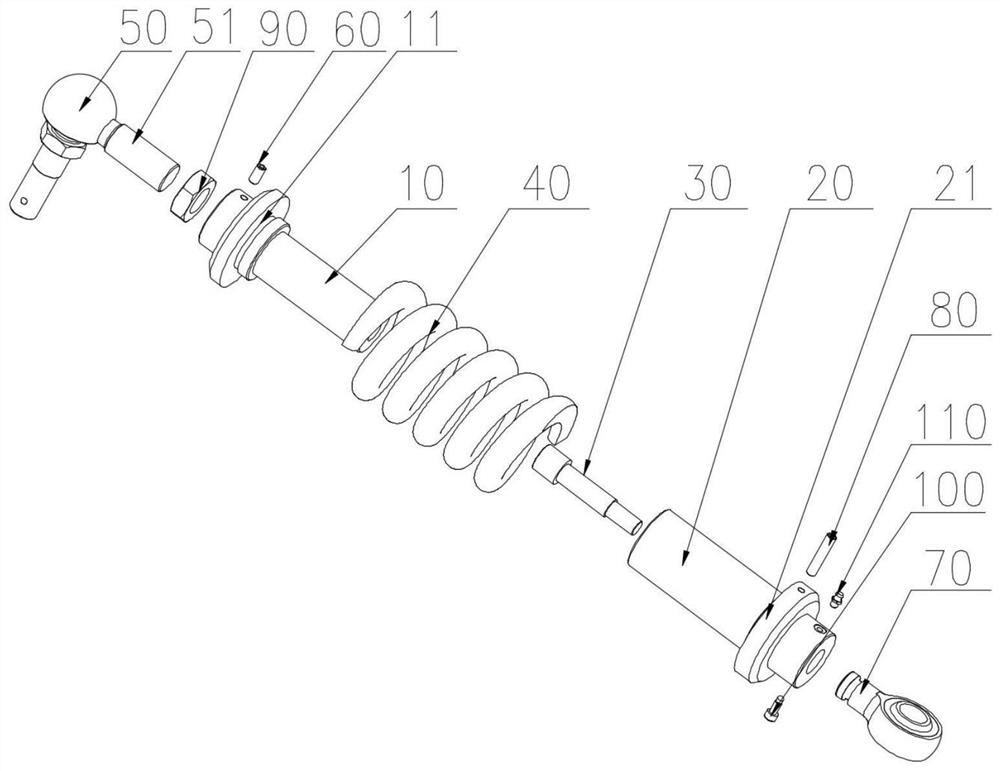

[0052] A spring 40 push rod mechanism, wherein, as figure 1 , 2 As shown, it includes: a first mandrel 10 , a second mandrel 20 , a spring 40 , a limit rod 30 , a ball joint bearing 50 , and a joint bearing 70 .

[0053] The first mandrel 10 has a first flange 11 located on the outer surface of the first mandrel 10 . The second mandrel 20 is telescopically connected with the first mandrel 10, and one end of the first mandrel 10 extends into the cavity of the second mandrel 20, the second mandrel 20 has a second flange 21, and the second flange 21 is located on the outer surface of the second mandrel 20 .

[0054] The spring 40 is disposed between the first mandrel 10 and the second mandrel 20 , and both ends of the spring 40 abut against the first flange 11 and the second flange 21 . The first mandrel 10 also has an accommodation chamber 12 and a through hole 13 , the through hole 13 passes through the accommodation chamber 12 and the cavity, and the diameter of the through...

Embodiment 2

[0082] A quick connection device, which includes the spring 40 push rod mechanism of any one of the technical solutions in the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com