Heat preservation and decoration integrated light steel keel composite wallboard and manufacturing method thereof

A light steel keel and composite wall panel technology, applied in the direction of heat preservation, walls, building components, etc., can solve the problems of long installation time, low production efficiency, increased self-weight, etc., to optimize the form of force, improve production efficiency, and heat preservation effect Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

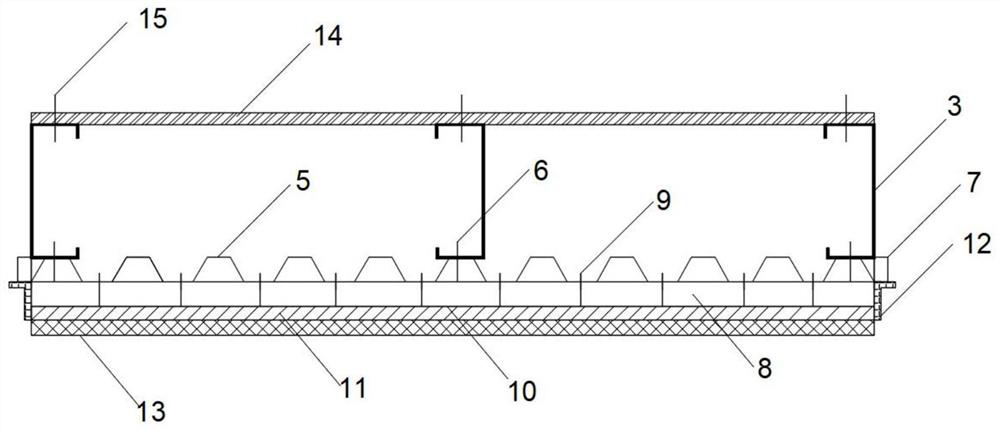

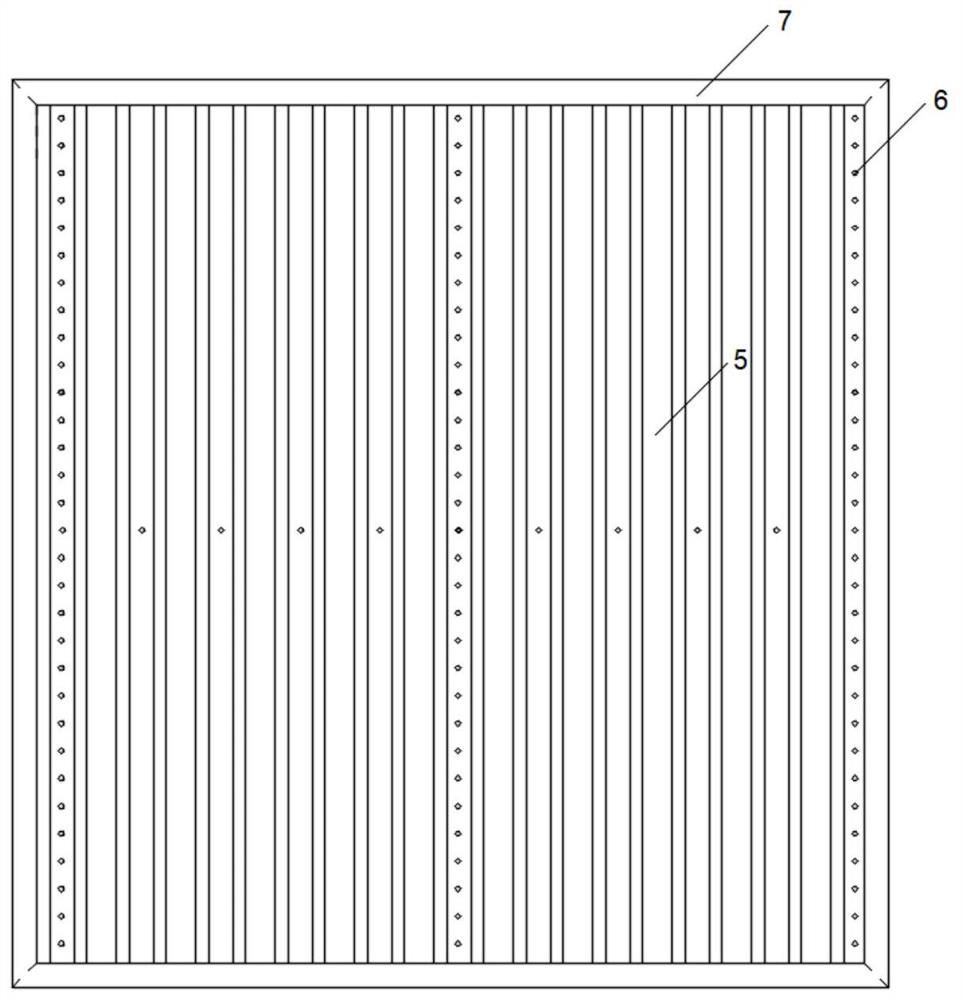

[0033] refer to figure 1 , a thermal insulation and decoration integrated light steel keel composite wallboard, comprising an outer decorative panel 13, an organic thermal insulation board 8, a profiled steel plate 5, a light steel keel, and an inner decorative panel 14, the profiled steel plate 5 covers the light steel keel, And combined with the light steel keel as a stress system to provide sufficient rigidity; the organic insulation board 8 covers the surface of the profiled steel plate 5 as an insulation layer; the outer decorative panel 13 is connected to the outermost side of the composite wallboard, and the inner decorative panel 14 is passed through Tapping screws 15 are attached to the inside of the light steel keel.

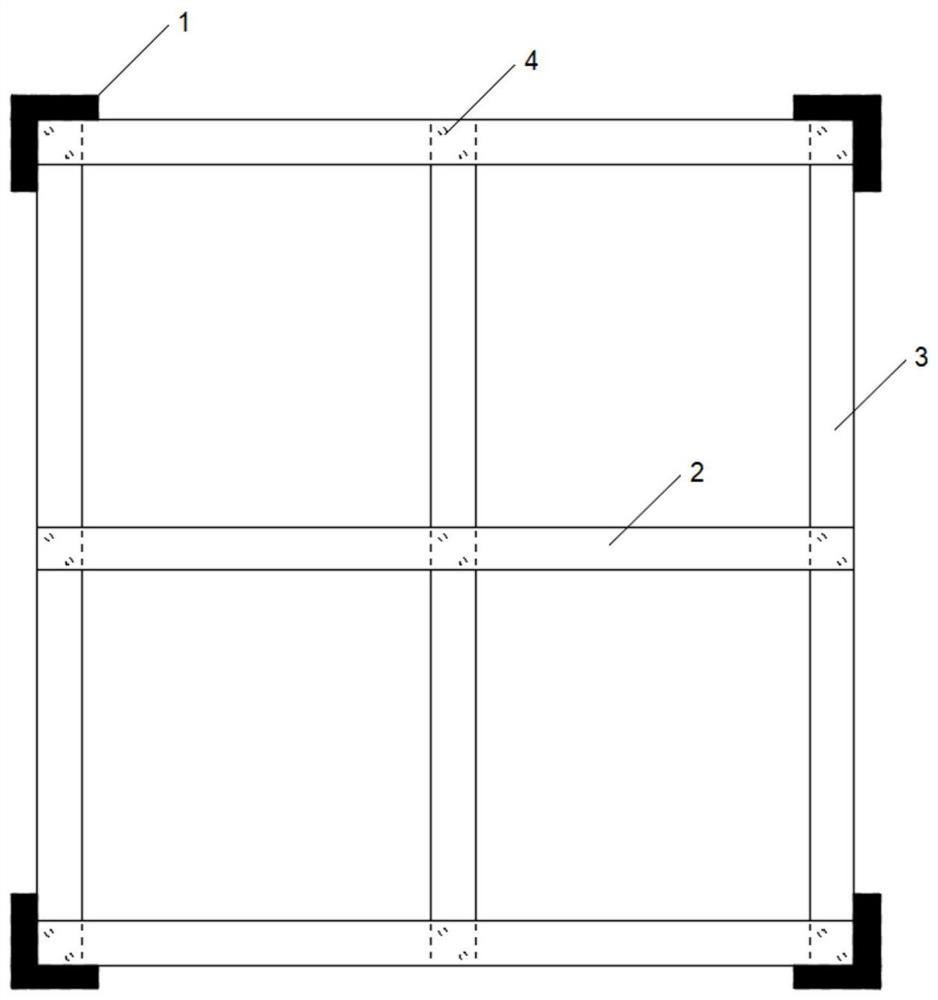

[0034] Such as figure 2 , the light steel keel is formed by intersecting the horizontal keel 2 and the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com