A kind of copper composite carbon fiber material and its preparation method and application

A composite carbon fiber and carbon fiber weaving technology, which is applied in the direction of carbon-silicon compound conductors, cables, insulated conductors, etc., can solve the problems of poor conductivity and reliability, achieve the effects of improving conductivity uniformity, improving dispersion uniformity, and preventing local deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

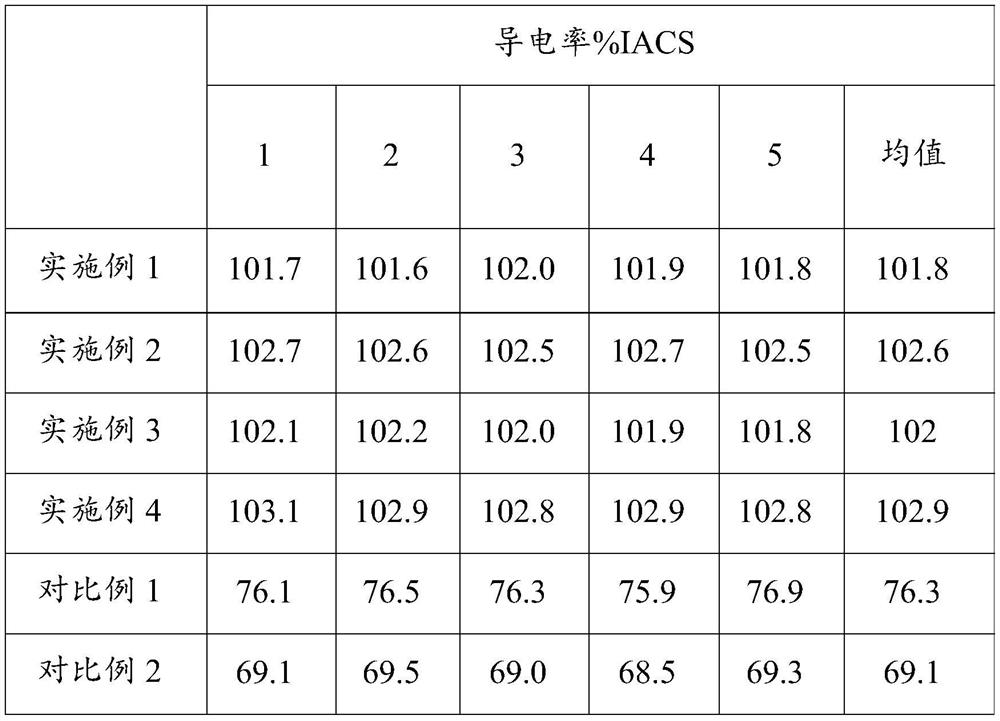

Examples

Embodiment 1

[0035] This embodiment provides a copper composite carbon fiber material, the preparation method of which is as follows:

[0036] Pre-treatment: Use T300 carbon fiber woven cloth with a pressure of 7MPa and a flow rate of 10m 3 After cleaning with distilled water per hour for 10 minutes; immerse in ethanol with a volume fraction of 65% and sonicate at room temperature for 15 minutes, with an ultrasonic frequency of 25000 Hz; 30000Hz.

[0037] Electroplating: The pre-treated carbon fiber woven cloth is used as the cathode, and the copper is used as the anode; then the cathode is immersed in an electrolytic aqueous solution at 50°C, and 0.3A / dm is passed through the electroplating circuit 2 electroplating with direct current for 2 hours to obtain metallized carbon fibers;

[0038] The electrolytic aqueous solution includes the following components: CuSO 4· h 2 O 100g / L; Ethylenediamine 100g / L; Jianna Green 1.2g / L; (NH 4 ) 2 SO 4 50g / L and Na2 SO 4 28g / L.

[0039] Post...

Embodiment 2

[0042] This embodiment provides a copper composite carbon fiber material, the preparation method of which is as follows:

[0043] Pre-treatment: Use T600 carbon fiber woven cloth with a pressure of 8MPa and a flow rate of 8m 3 After cleaning with distilled water per hour for 7 minutes; immerse in ether for 20 minutes at room temperature and ultrasonic frequency at 20,000 Hz; then take out the T600 carbon fiber woven cloth and immerse it in 40 wt% sodium hydroxide aqueous solution for room temperature and ultrasonic at 25,000 Hz.

[0044] Electroplating: The pre-treated carbon fiber woven cloth is used as the cathode, and the copper is used as the anode; then the cathode is immersed in an electrolytic aqueous solution at 40°C, and 0.4A / dm is passed through the electroplating circuit 2 electroplating with direct current for 1.5h to obtain metallized carbon fibers;

[0045] The electrolytic aqueous solution includes the following components: CuSO 4· h 2 O 70g / L; Ethylenediamin...

Embodiment 3

[0049] This embodiment provides a copper composite carbon fiber material, the preparation method of which is as follows:

[0050] Pre-treatment: Use T800 carbon fiber woven cloth with a pressure of 5MPa and a flow rate of 9m 3 After cleaning with distilled water per hour for 5 minutes; immerse in ethanol with a volume fraction of 70% and sonicate at room temperature for 30 minutes, with an ultrasonic frequency of 30,000 Hz; 20000Hz.

[0051] Electroplating: The pre-treated carbon fiber woven cloth is used as the cathode, and the copper is used as the anode; then the cathode is immersed in an electrolytic aqueous solution at 60°C, and 0.5A / dm is passed through the electroplating circuit 2 electroplating with direct current for 1 hour to obtain metallized carbon fibers;

[0052] The electrolytic aqueous solution includes the following components: CuSO 4· h 2 O 80g / L; Ethylenediamine 100g / L; Jianna Green 2g / L; (NH 4 ) 2 SO 4 60g / L and Na 2 SO 4 20g / L.

[0053] Post-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com