Method for micropore filling by using CTAB as inhibition additive

An additive, microporous technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unavoidable filling defects, ineffective transportation, limited transportation capacity, etc., to achieve high effective coverage, The effect of good filling effect and strong inhibition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

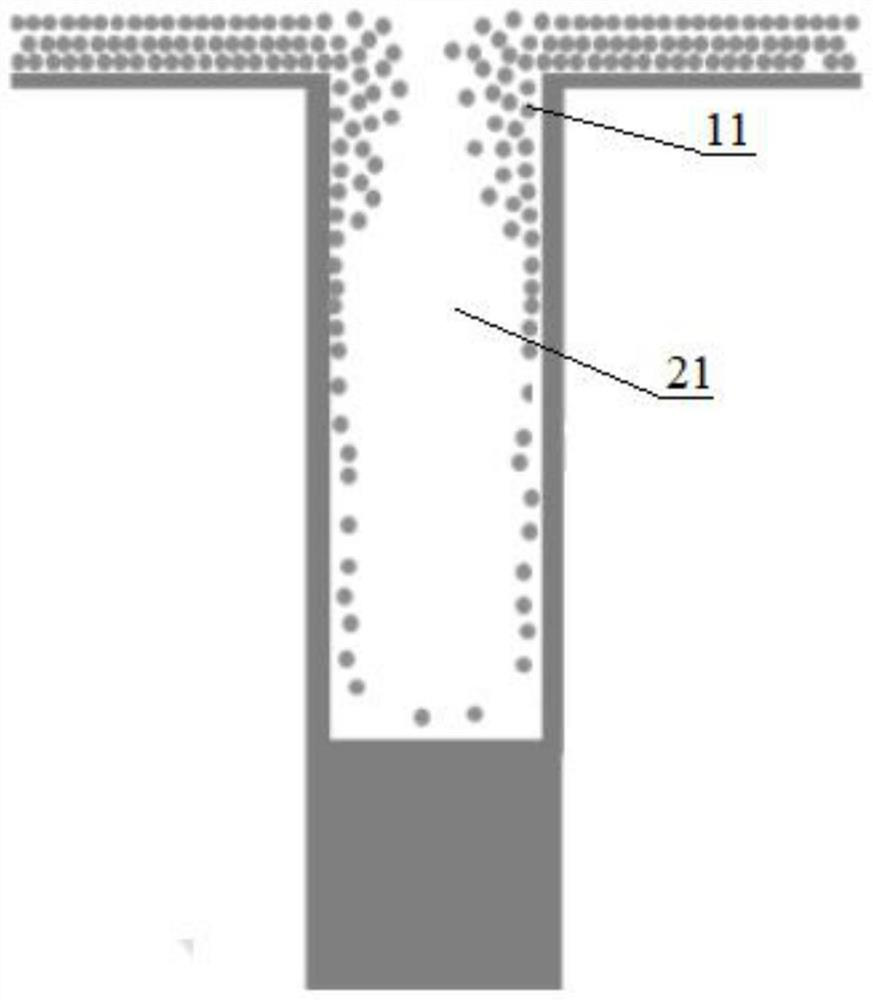

[0036] In this example, CTAB11 was used as the only electroplating additive to conduct a micropore electroplating filling experiment, and the micropore size was 20 μm in diameter and 60 μm in depth.

[0037] The filling method is as follows:

[0038] Step 1, prepare the electroplating base solution:

[0039] Add copper sulfate, sodium chloride, sulfuric acid, etc. into deionized water, stir well to form the electroplating base solution, and set aside;

[0040] The concentration of copper sulfate in the electroplating base solution is 200g / L, the concentration of sodium chloride is 0.1g / L, and the concentration of sulfuric acid is 64mL / L;

[0041] Step 2, prepare electroplating solution 1:

[0042] Add an appropriate amount of CTAB11 to the electroplating base solution obtained in step 1, so that the concentration of CTAB11 is 0.3g / L, and prepare the micropore filling electroplating solution 1;

[0043] Step 3, assemble the electrodes:

[0044] Use dilute sulfuric acid and ...

Embodiment 2

[0051] In this embodiment, CTAB11 is used as the only electroplating additive to carry out the micropore electroplating filling experiment, and the micropore size is preferably 20 μm in diameter and 200 μm in depth.

[0052] The filling method is as follows:

[0053] Step 1, prepare the electroplating base solution:

[0054] Add copper sulfate, sodium chloride, sulfuric acid, etc. into deionized water, stir well to form the electroplating base solution, and set aside;

[0055] The concentration of copper sulfate in the electroplating base solution is 200g / L, the concentration of sodium chloride is 0.2g / L, and the concentration of sulfuric acid is 64mL / L;

[0056] Step 2, prepare electroplating solution 1:

[0057] Add an appropriate amount of CTAB11 to the electroplating base solution obtained in step 1, so that the concentration of CTAB11 is 0.33g / L, and prepare the electroplating solution 1 filled with micropores 21;

[0058] Step 3, assemble the electrodes:

[0059] Use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com