Adjustable high-temperature liquid state steel slag granulating device

A liquid steel slag, adjustable technology, applied in the field of adjustable high temperature liquid steel slag granulation device, can solve the problems of poor quality of granulated products and inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

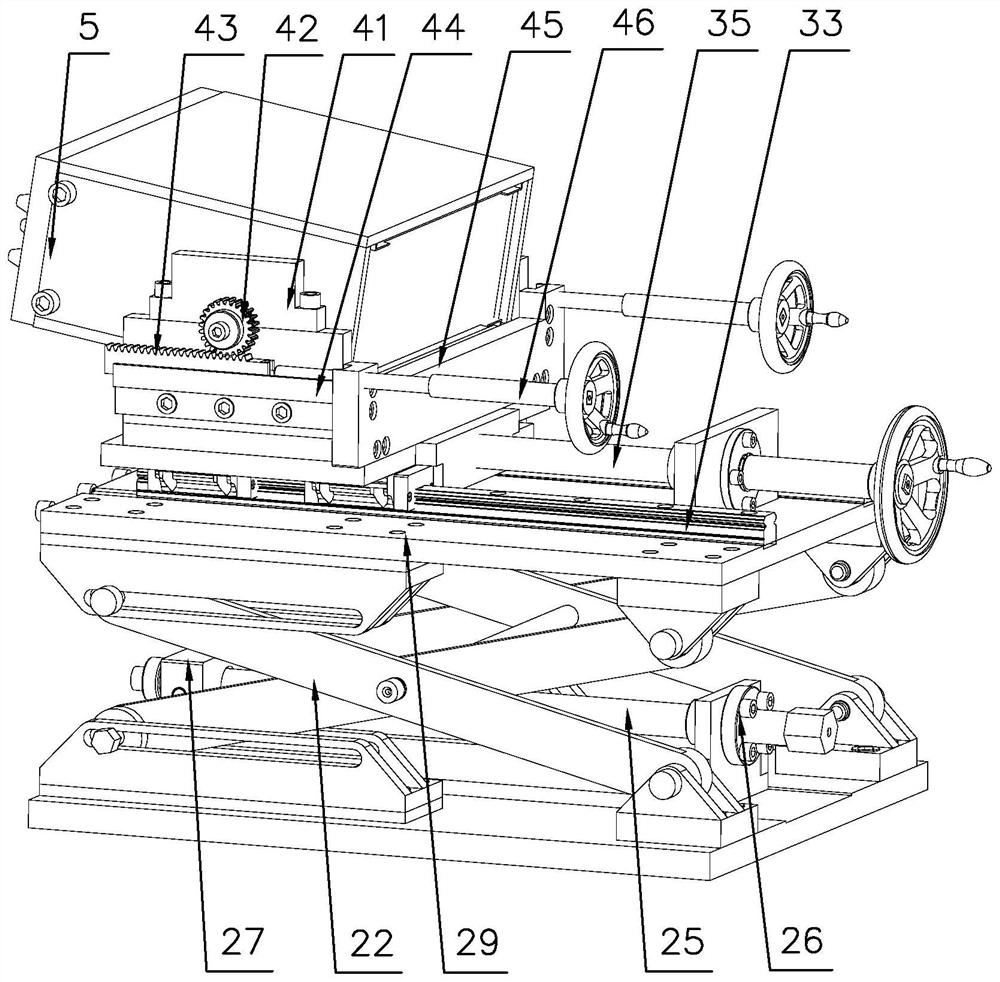

[0024] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-5 , to further specifically describe the technical solution of the present invention.

[0025] An adjustable high-temperature liquid steel slag granulation device, comprising a steel slag granulator 6, an air pipeline 7, an airflow adapter 8, an airflow booster pipeline 81, an air storage tank 9, a compressed air pipeline 91, and a regulating valve 92. One side of the air storage tank 9 is provided with a compressed air pipeline 91, one side of the compressed air pipeline 91 is provided with a regulating valve 92, the other side of the compressed air pipeline 91 is provided with an airflow booster pipeline 81, and one side of the airflow booster pipeline 81 An air flow adapter 8 is provided, one side of the air flow adapter 8 is provided with an air pipeline 7, one side of the air pipeline 7 is provided with a steel slag granulator 6, the air storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com