Porous alumina composite shaped phase change material and preparation method thereof

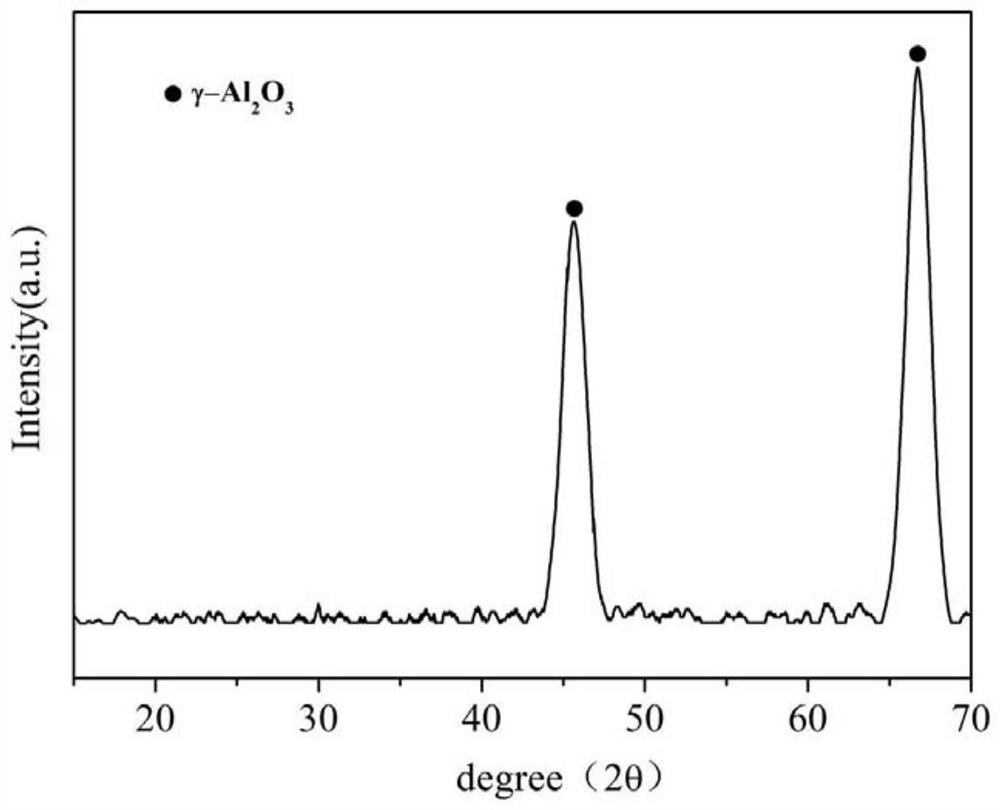

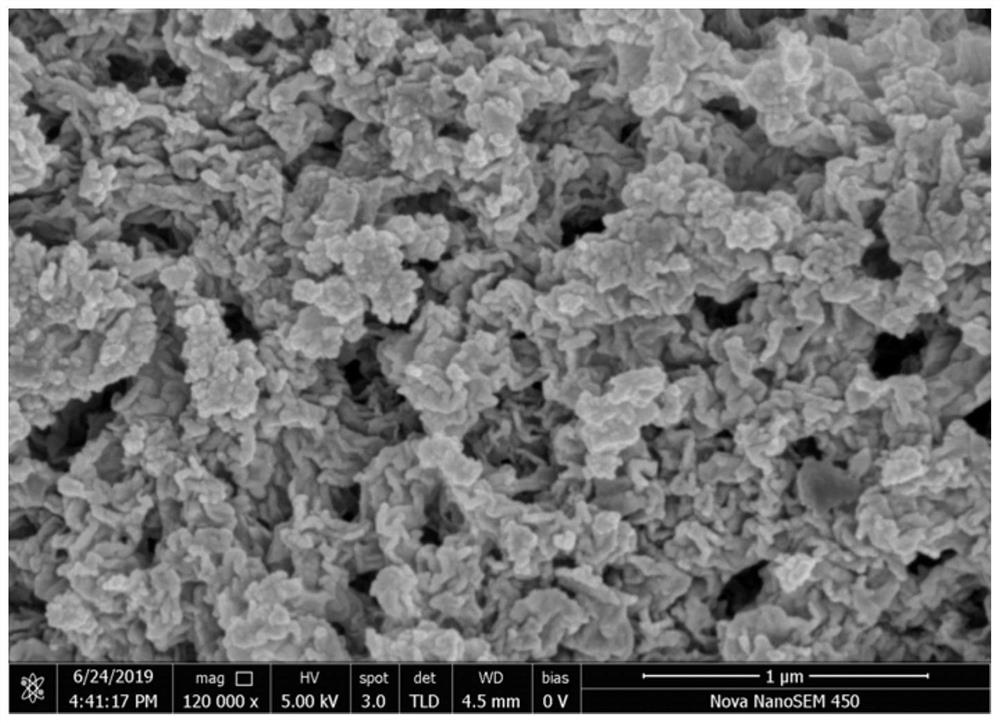

A technology of porous alumina and phase change materials, applied in chemical instruments and methods, botanical equipment and methods, heat exchange materials, etc., can solve the problems of plant growth temperature, phase stratification, liquid phase leakage, and thermal conductivity. Large and other problems, to achieve the effect of enhanced heat storage and release function, high phase transition temperature, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

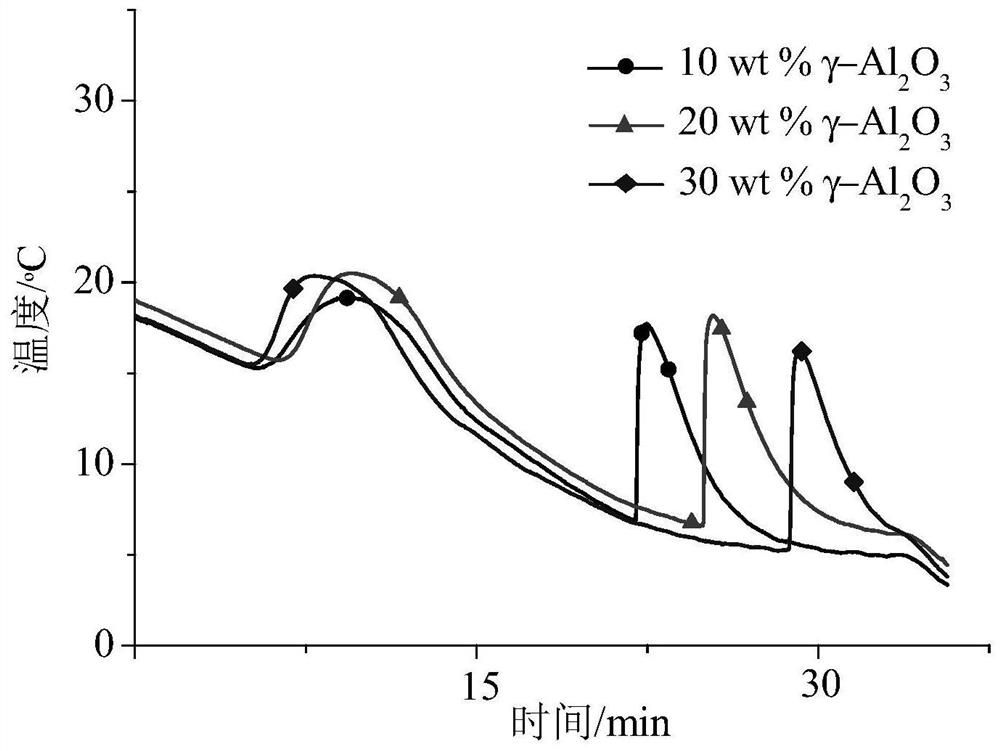

[0049] Raw material ratio: Na 2 SO 4 10H 2 O 70wt%, porous alumina 30wt%; preparation steps are as follows ( Figure 4 ):

[0050] First, weigh 20g Na with an electronic balance 2 SO 4 10H 2 O, put it in a beaker, seal the beaker with plastic wrap, place it in a constant temperature water bath at 50°C and heat it for 1 hour to obtain a molten sample.

[0051] Then take out the beaker, uncover the plastic wrap, add porous alumina to the molten sample, cover the plastic wrap and continue to stir and mix at 50°C for 2 hours to make the raw materials evenly stirred. Finally, peel off the plastic wrap, put the beaker into a vacuum drying oven, use a vacuum pump to remove the air in the drying oven until the pressure of the vacuum drying oven is 40kpa, and vacuum physical adsorption for 4 hours at room temperature to prepare a porous alumina composite shaped phase transition Material( Image 6 ).

[0052] The step cooling curve (see image 3 ) and the DSC curve at a heatin...

example 2

[0054] Raw material ratio: Na 2 SO 4 10H 2 O 80wt%, porous alumina 20wt%; The preparation steps are as follows ( Figure 4 ):

[0055] First, weigh 20g Na with an electronic balance 2 SO 4 10H 2 O, put it in a beaker, seal the beaker with plastic wrap, place it in a constant temperature water bath at 50°C and heat it for 1 hour to obtain a molten sample.

[0056] Then take out the beaker, uncover the plastic wrap, add porous alumina to the molten sample, cover the plastic wrap and continue to stir and mix at 50°C for 2 hours to make the raw materials evenly stirred. Finally, peel off the plastic wrap, put the beaker into a vacuum drying oven, use a vacuum pump to remove the air in the drying oven until the pressure of the vacuum drying oven is 40kpa, and vacuum physical adsorption for 4 hours at room temperature to prepare a porous alumina composite shaped phase transition Material.

[0057] The step cooling curve of the obtained composite shaped phase change material ...

example 3

[0059] Raw material ratio: Na 2 SO 4 10H 2 O 90wt%, porous alumina 10wt%; preparation steps are as follows ( Figure 4 ):

[0060] First, weigh 20g Na with an electronic balance 2 SO 4 10H 2 O, put it in a beaker, seal the beaker with plastic wrap, place it in a constant temperature water bath at 50°C and heat it for 1 hour to obtain a molten sample.

[0061] Then take out the beaker, uncover the plastic wrap, add porous alumina to the molten sample, cover the plastic wrap and continue to stir and mix at 50°C for 2 hours to make the raw materials evenly stirred. Finally, peel off the plastic wrap, put the beaker in a vacuum drying oven, use a vacuum pump to remove the air in the drying oven until the pressure of the vacuum drying oven is 35kpa, and vacuum physical adsorption for 4 hours at room temperature to prepare a porous alumina composite shaped phase transition Material.

[0062] The step cooling curve of the obtained composite shaped phase change material at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com