Environment-friendly silicone grease for fixing small-size nanocrystalline magnetic core and preparation method

An environmentally friendly, nanocrystalline technology, applied in the direction of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of attenuation, fixed small-sized nanocrystalline magnetic cores, etc., and solve the problem of serious performance attenuation , Overcoming low production efficiency and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

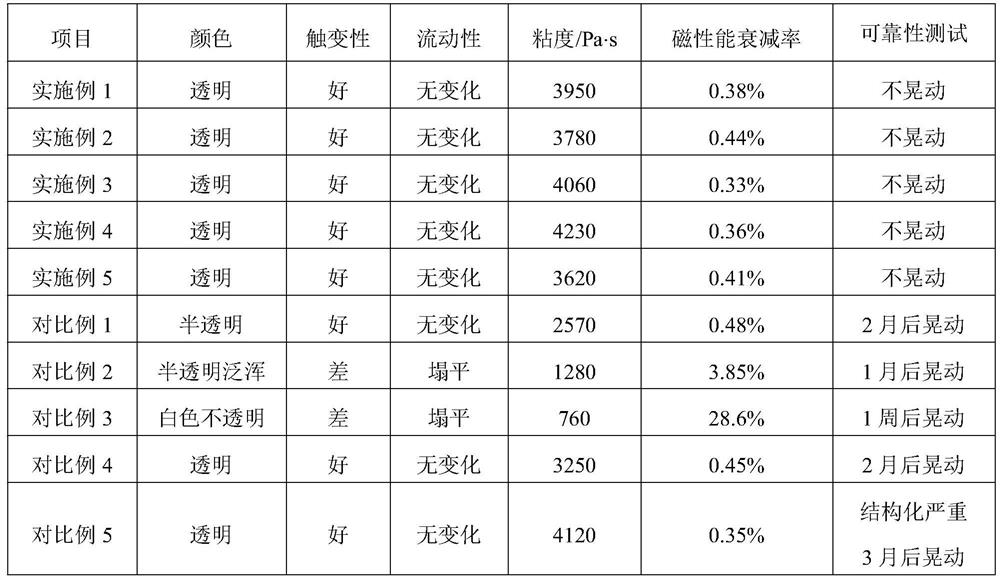

Examples

Embodiment 1

[0034] Add 100 parts of methyl-terminated polydimethylsiloxane (25°C, 80000mPa·s) into the kneader, and add 40 parts of hydrophilic fumed silica (BET=300m 2 / g) and 12 parts of trimethylethoxysilane, kneaded at normal pressure for 4 hours; heated to 190°C, kneaded at -0.095MPa for 4 hours, then ground twice by three-roll mill; transferred the material to a planetary mixer Add 1 part of trimethylsilanol, and mix under vacuum at -0.095Mpa for 30 minutes to prepare a silicone grease sample.

Embodiment 2

[0036] Add 100 parts of methyl-terminated polydimethylsiloxane (25°C, 80000mPa·s) into the kneader, and add 60 parts of hydrophobic fumed silica (BET=300m 2 / g) and 8 parts of trimethylmethoxy silicone oil, kneading at normal pressure for 4 hours; heating up to 190°C, kneading at -0.095MPa for 4 hours, then grinding twice with a three-roll mill; transferring the material to a planetary mixer Add 1 part of hydroxyl silicone oil (25°C, 30mPa·s), and mix under vacuum at -0.095Mpa for 30 minutes to prepare a silicone grease sample.

Embodiment 3

[0038] Add 100 parts of vinyl-terminated polydimethylsiloxane (25°C, 100000mPa·s) into the kneader, and add 30 parts of hydrophilic fumed silica (BET=400m 2 / g) and 10 parts of dimethyldimethoxysilane, kneaded at normal pressure for 2 hours; heated up to 180°C, kneaded at -0.095MPa for 6 hours, then ground twice with a three-roller mill; transferred the material to planetary mixing In the machine, add 1 part of trimethylsilanol, and mix under vacuum at -0.095Mpa for 45 minutes to prepare a silicone grease sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com