Flocculating yeast bioadhesive as well as preparation method and use method thereof

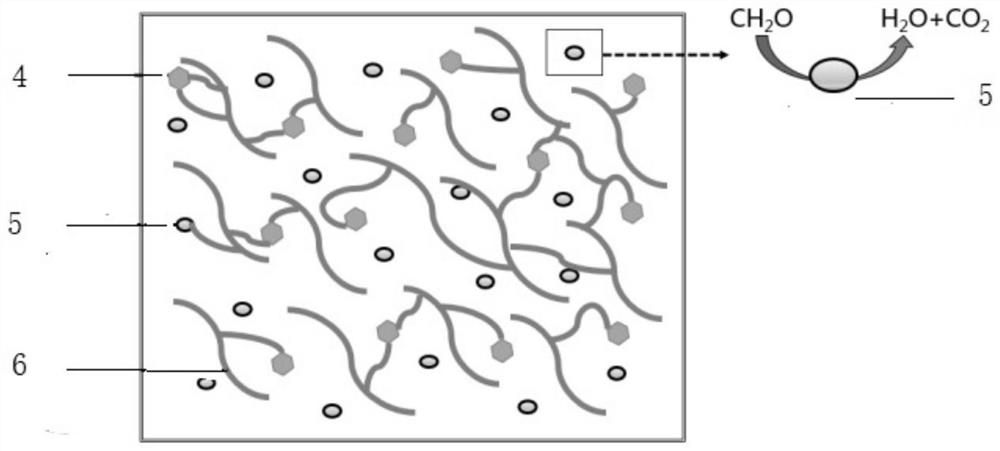

A bioadhesive and flocculation technology, applied in biochemical equipment and methods, microbial-based methods, adhesive types, etc., can solve the problem of expensive mussel adhesion protein, high cost of adhesion protein extraction, and limited biological adhesion In order to achieve low irritation, low antibacterial effect and reduce the release of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1D

[0053] Example 1 The extraction method of the protein rich in Dopa content:

[0054] Take the feet of live marine mussels, wash them with PBS at -5°C to 0°C, chop them in a 5% acetic acid solution containing protease inhibitors at -5°C to 0°C, and chop the above materials with a disperser , the mixture was homogenized on ice;

[0055] The treated tissue homogenate was centrifuged, and the supernatant was separated, and 60% perchloric acid (PCA) was slowly added to the supernatant in an ice bath at the same time to a final concentration of 1%, stirred for 20-40 minutes, centrifuged, and recovered. Serum;

[0056] Cool the supernatant in -10°C to -20°C ice ethanol, add concentrated sulfuric acid to acidify to a final concentration of 0.3mmol / L while stirring, add twice the volume of -82°C to Acetone at -86°C;

[0057] After standing still for 20-30 minutes, centrifuge, discard the supernatant, take the precipitate and dissolve it in 5% acetic acid, centrifuge again, take the ...

Embodiment 2

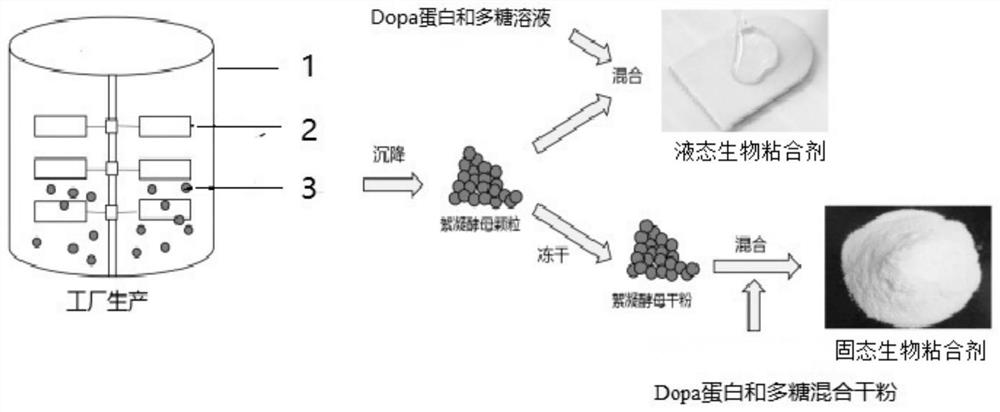

[0058] Example 2 Preparation of flocculated yeast bioadhesive

[0059] Preparation of flocculated yeast bioadhesives as figure 1 As shown in the flow chart of the preparation of the flocculated yeast bioadhesive, the flocculated Saccharomyces cerevisiae is factory-produced through a fermenter 1, and the tank body of the fermenter 1 is provided with a baffle, an aeration and a stirring blade 2. The cultured flocculated Saccharomyces cerevisiae 3 can be prepared into two forms of bioadhesives, namely liquid and solid. When the cells are settled, a liquid bioadhesive can be obtained; when the cells are made into a dry powder, they are mixed with Dopa-rich protein and polysaccharide mixed dry powder to make a solid bioadhesive.

[0060] 1. The preparation process of liquid flocculation yeast bioadhesive:

[0061] Take the flocculated Saccharomyces cerevisiae cryopreservation solution from the refrigerator at -80°C, inoculate it into YPD seed medium (1% yeast extract, 2% peptone,...

Embodiment 3

[0069] Embodiment 3 liquid bioadhesive or activated solid bioadhesive is used to prepare plywood

[0070] Rotate the wood section material into 1-2mm veneers with a rotary cutter, and dry the veneers with a hot air stove until the water content is 10-12%, and mix carbon fiber powder and liquid wear-resistant rubber by 0.05-0.1: The weight ratio of 1 is evenly mixed to obtain a wear-resistant coating;

[0071] The above-mentioned wear-resistant coating is evenly coated on the prepared veneer, and air-dried naturally, the amount of the wear-resistant coating is 100-200g / m 2 ;

[0072] Use a glue applicator to coat the adhesive on both sides of the prepared veneer, and the amount of flocculated yeast bioadhesive is 280-300g / m 2 , the flocculated yeast bioadhesive is a liquid bioadhesive or an activated solid bioadhesive, after gluing, it is assembled, and the veneers after gluing are arranged in a criss-cross pattern and bonded together according to the wood texture structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com