Preparation method of composite particle with hairy structure on surface

A technology of composite particles and nanoparticles, which is applied in the field of preparation of composite particles, can solve the problems of inappropriate preparation of hairy structures, cumbersome preparation process of template method, and inability to prepare large-scale preparations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

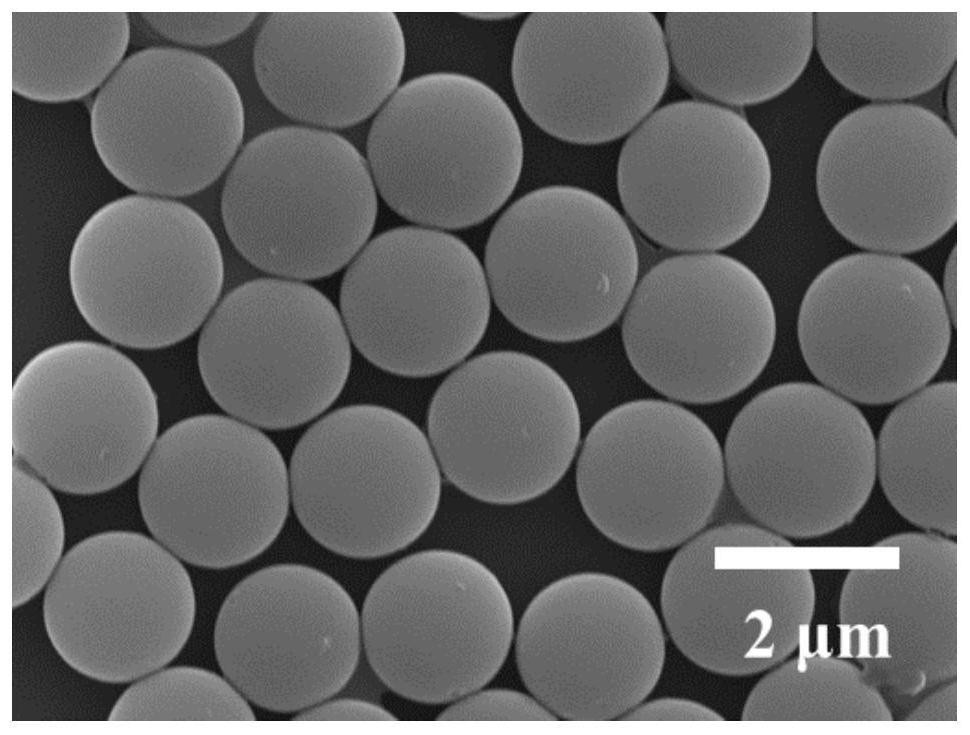

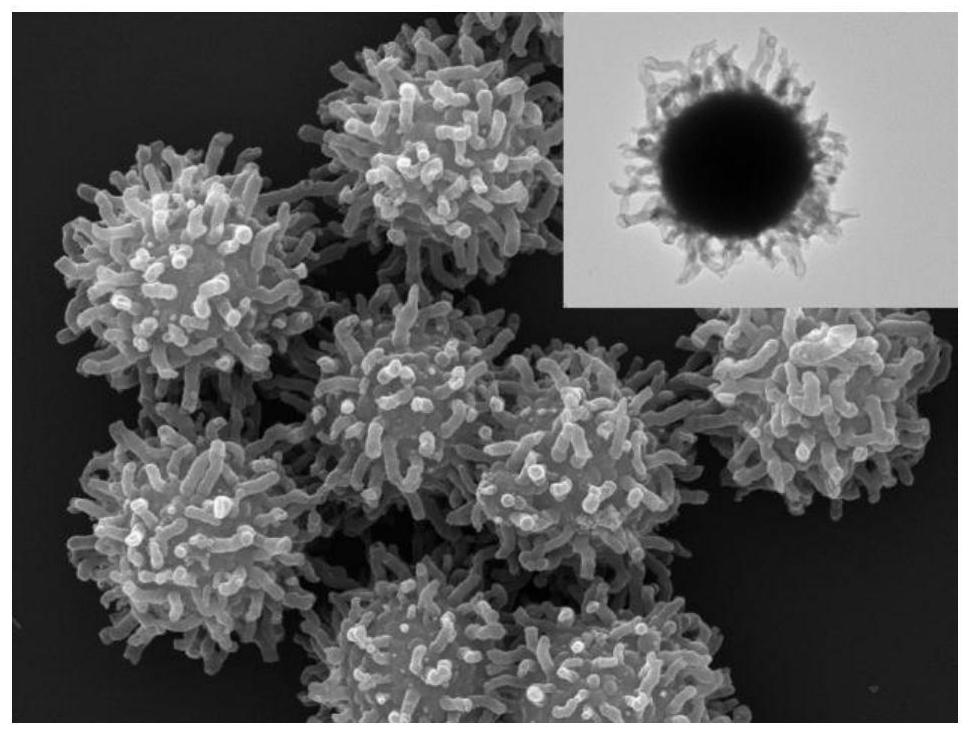

[0049] Embodiment 1, in-situ growth of PDVB nanofibers on the surface of silica microspheres

[0050] Add 200mg of silica microspheres to 50ml of n-heptane solution dissolved with 100mg of Span-80 (Span-80, the volume concentration in n-heptane is 2‰), ultrasonic 15min to make the silica uniform in the solution dispersion.

[0051]Then add 100 μL of boron trifluoride etherate complex (BFEE, the volume concentration in the system is 2‰), and add 1ml of divinylbenzene monomer (DVB, the volume concentration in the system is 2%) after 30 seconds, After reacting at room temperature for 10 minutes, excess ethanol was added to quench the reaction (the quenching of cationic polymerization can be judged by the appearance color, when adding ethanol, the color of the system will change from orange red to white, accompanied by the release of HF gas). The entire reaction process was carried out under ultrasonic conditions.

[0052] After the reaction, the product was centrifuged and wash...

Embodiment 2

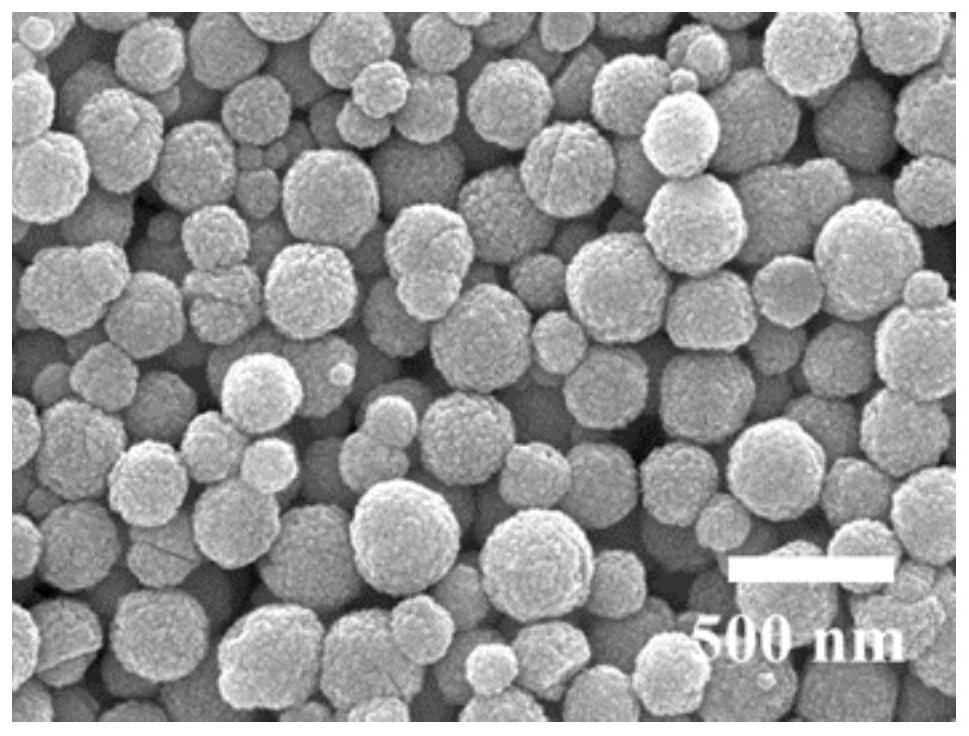

[0054] Embodiment 2, in-situ growth of PDVB nanofibers on the surface of silica microspheres

[0055] Add 200 mg of silicon dioxide microspheres into 50 ml of n-heptane solution dissolved with 100 mg of Span-80 (Span-80), and ultrasonically disperse the silicon dioxide in the solution for 15 minutes.

[0056] Then add 100μL boron trifluoride ether complex (BFEE), add 1ml divinylbenzene monomer (DVB) after reacting for 30s, add excess ethanol to quench the reaction after reacting at room temperature for 3min (the quenching of cationic polymerization can be judged by the appearance Judging by the color, when the addition of ethanol is terminated, the color of the system will change from orange red to white, accompanied by the release of HF gas). The entire reaction process was carried out under ultrasonic conditions.

[0057] Electron micrographs show that SiO 2 Nanofibers have not been formed on the surface of the particles, only a rough polymer shell (forming a transition st...

Embodiment 3

[0058] Embodiment 3, grow PDVB-PVBC nanofiber in situ on the surface of silica microspheres

[0059] Add 200mg of silica microspheres into 50ml of n-heptane solution dissolved with 100mg of Span-80, and ultrasonically disperse the silica for 15min.

[0060] Add 100 μL boron trifluoride diethyl ether (volume concentration in the system is 2‰), react for 30 seconds, add 1ml DVB, and react at room temperature for 10 minutes.

[0061] 200 μL of benzylchlorostyrene (VBC, volume concentration in the system: 0.4%) was added to the system once, and after 5 minutes of reaction, excess ethanol was added to terminate the reaction. The product PDVB-VBC@SiO was obtained after centrifugation and washing with ethanol for 3 times 2 .

[0062] The fiber is divided into two segments, one of which is close to the SiO 2 A section of the composition is PDVB nanofibers, the one facing the outside Duan Cheng Divided into PVBC nanofibers, the length of PVBC segment is about 250nm.

[0063] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com