Double-sided anti-skid glass with fragment polymerization function and forming mold of double-sided anti-skid glass

A polymerization function and forming mold technology, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as high risk factor, personal safety injury, and easy breakage under force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

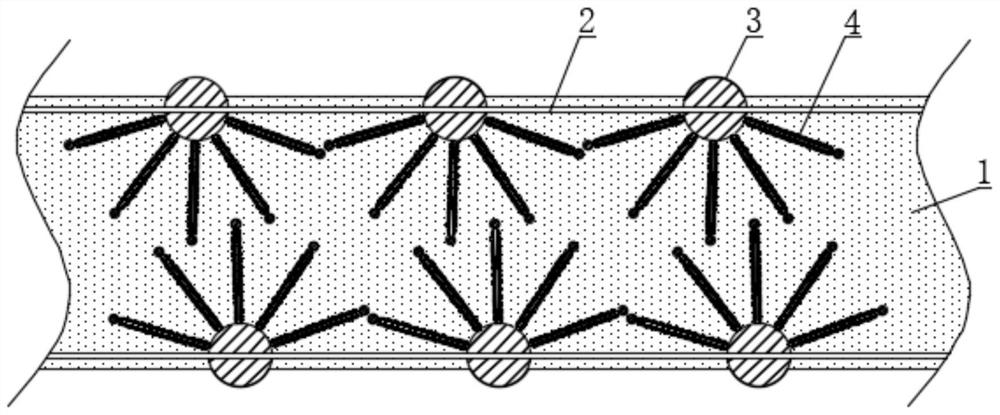

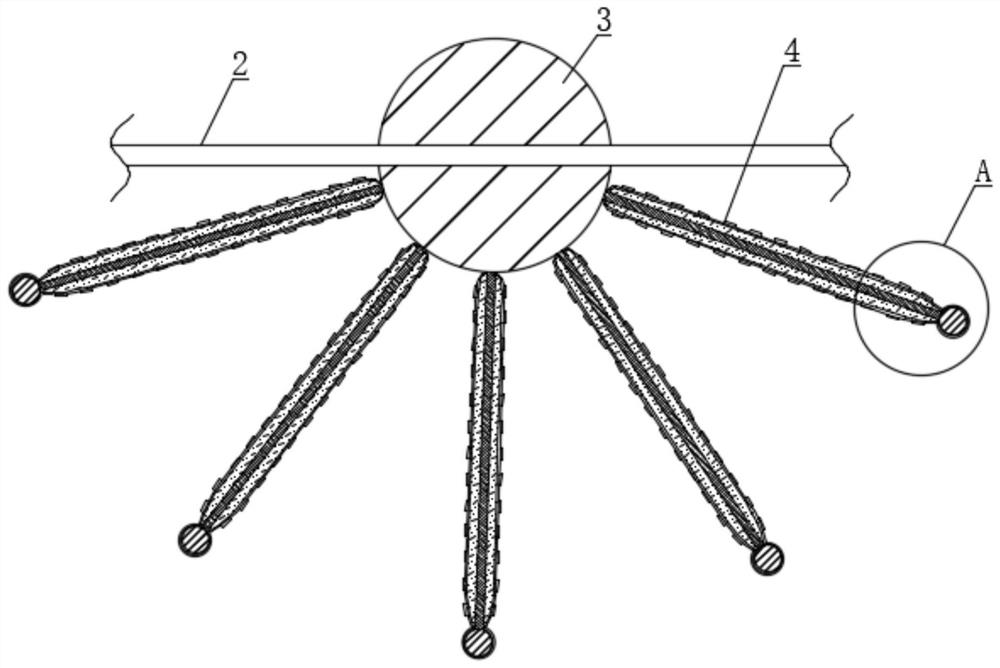

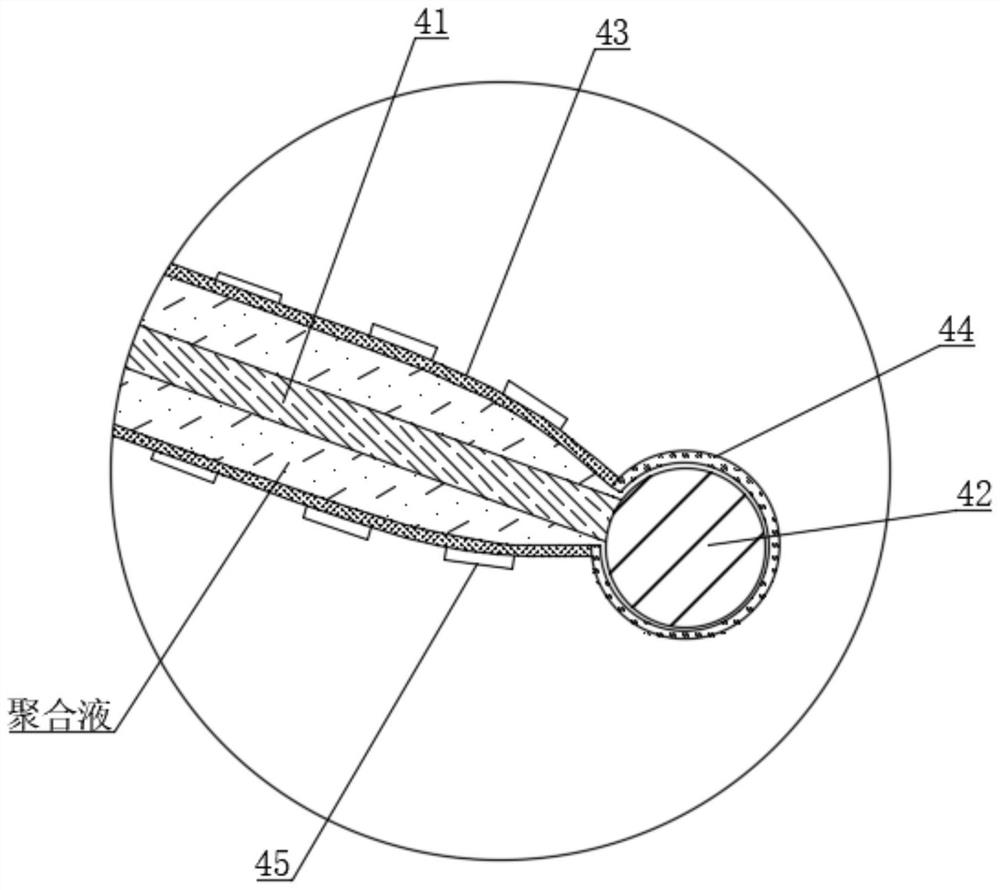

[0040] see figure 1 with figure 2 , a double-sided anti-slip glass with fragment aggregation function, comprising a glass plate 1, the interior of the glass plate 1 is provided with a linear anti-slip filler, the linear anti-slip filler includes a center line 2, and a plurality of evenly arranged anti-slip balls are arranged on the center line 2 3. The center line 2 runs through the interior of the anti-skid ball 3 and is fixedly connected with the anti-skid ball 3. The outer surface of the anti-skid ball 3 is fixedly connected with a plurality of uniformly distributed aggregate branches 4, and the multiple aggregate branches 4 on a single anti-skid ball 3 are in the shape of a hedgehog. shape is evenly distributed on the half spherical surface of the anti-skid ball 3, the polymerization branch line 4 is located inside the glass plate 1, and the other hemispherical surface without the polymerization branch line 4 on the anti-skid ball 3 can be located on the outside of the gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com