Slaughter wastewater treatment method and system

A technology of slaughter wastewater and treatment methods, which is applied in animal processing wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., and can solve the problems of low treatment cost and low energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

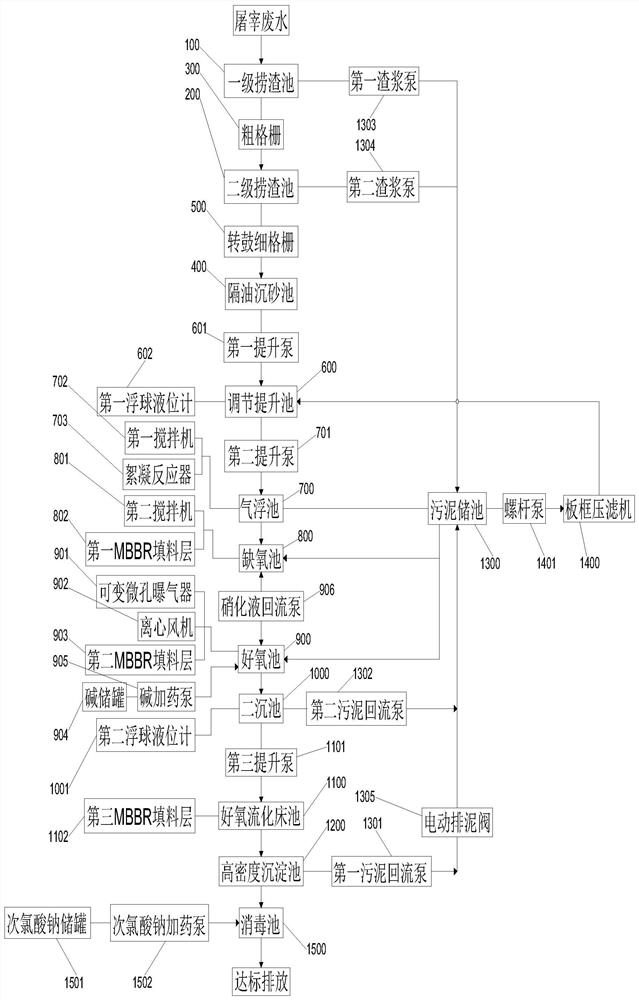

[0054] Such as figure 1The slaughter wastewater treatment system shown includes a first-level slag removal tank 100, a second-level slag removal tank 200 is connected to the first-level slag removal tank through pipelines, and the pipeline between the second-level slag removal tank and the first-level slag removal tank is equipped with There are coarse grids 300, and the oil-separating grit chamber 400 is connected to the secondary slag tank through pipelines, and the drum fine grid 500 is installed in the pipeline between the oil-separating grit tank and the secondary slag tank. The grit chamber is connected with a regulating lifting tank 600 through a pipeline, and a first lifting pump 601 is provided on the pipeline between the regulating lifting tank and the oil separation grit chamber, and an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com