Automatic filament feeding device provided with roller type deviation rectifying mechanism and used for EPP granulator

A technology of wire feeding device and granulator, which is applied in the direction of conveying filamentous materials, transportation and packaging, thin material processing, etc., which can solve the problem of inability to accurately feed into granulator, increase the labor cost of enterprises, and difficulty in shaping EPP filaments. and other problems, to achieve the effect of improving production fluency, improving wire feeding accuracy, and preventing accidental downward tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

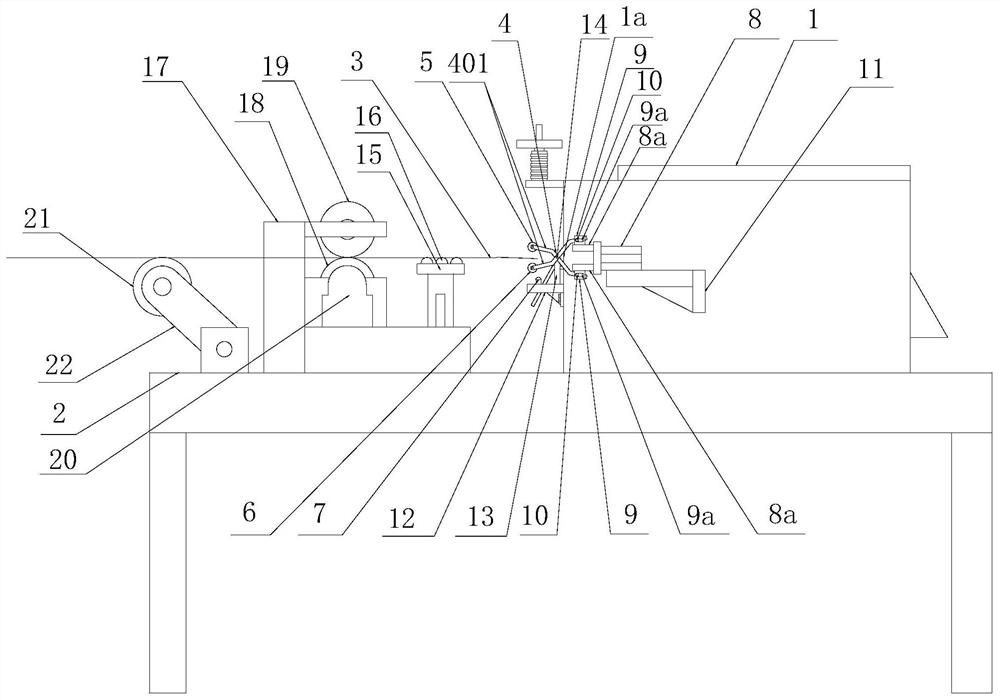

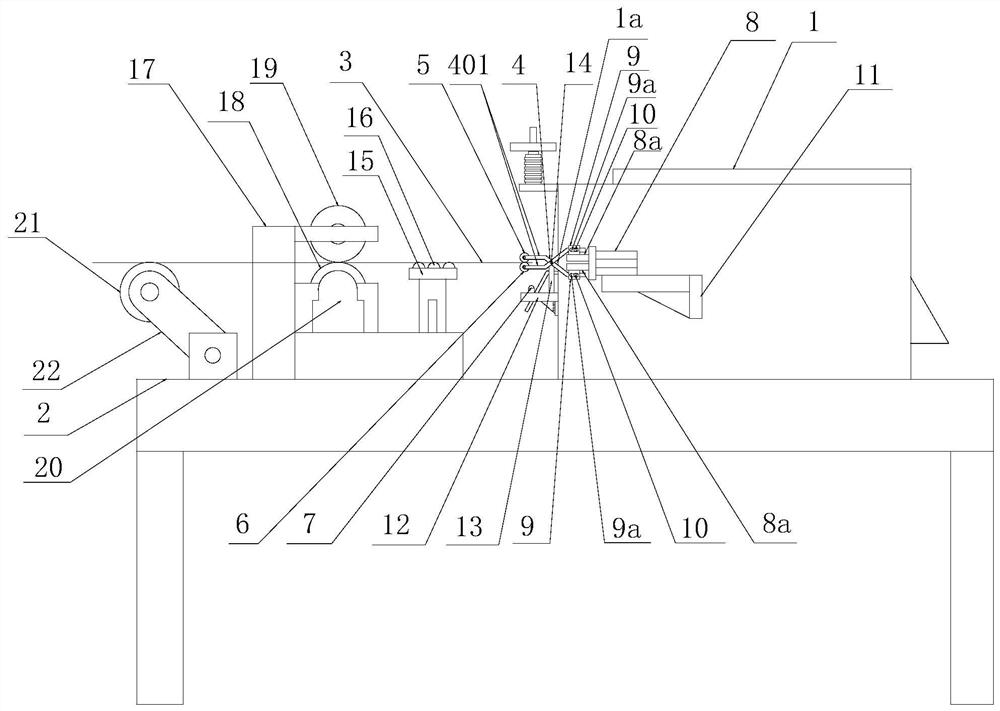

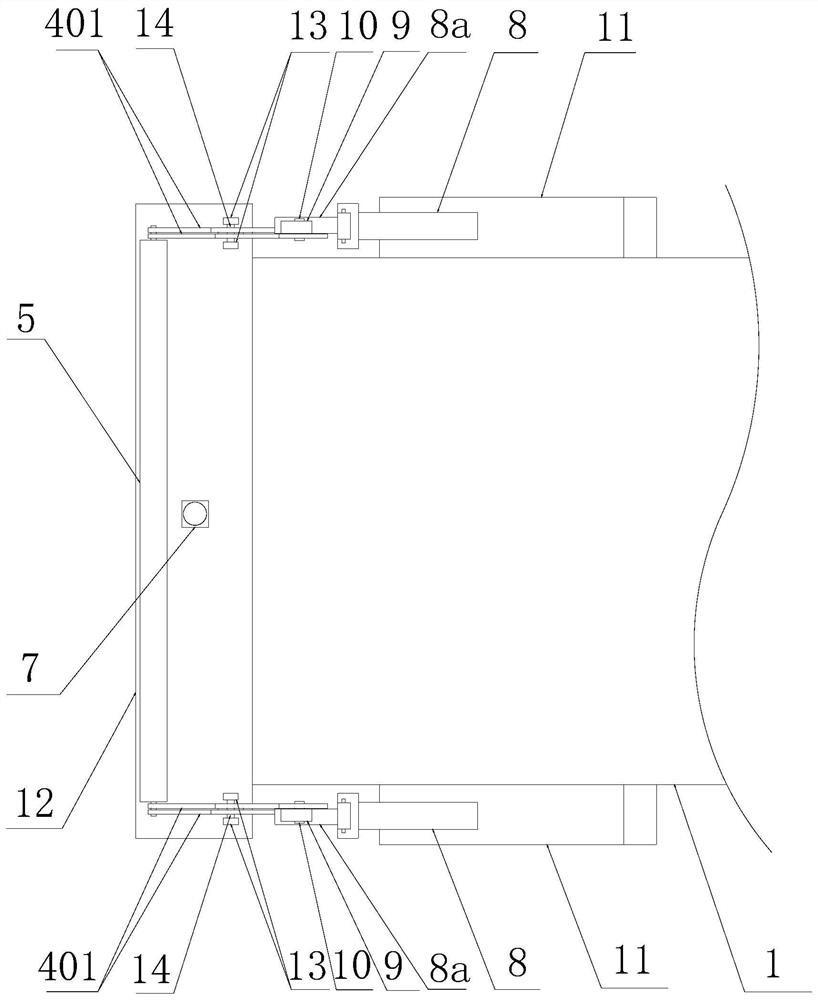

[0034] Example: Combine Figure 1~Figure 4 The specific implementation of the EPP granulator automatic wire feeding device provided by the present invention with a roller-type deviation correction mechanism is described as follows:

[0035] first as figure 1 and figure 2 As shown, the EPP granulator automatic wire feeding device with a roller-type deviation correction mechanism has a conveying roller mechanism arranged on the machine platform 2 of the EPP granulator 1, and at the same time, the conveying roller mechanism on the machine platform 2 The front (that is, the upstream of the wire feed direction of the EPP filament) is fixed with a feed support 22, and the feed support 22 is pivotally provided with a feed roller 21 for supporting the EPP filament 3, while the conveyor roller mechanism and the EPP cutter A supporting bracket 15 is fixed on the machine platform 2 between the granulator 1, and a supporting roller group 16 for supporting the EPP filament 3 is pivoted on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com