Lower sliding rail profile for automobile seat and manufacturing method thereof

A technology for car seats and profiles, applied to vehicle seats, movable seats, vehicle parts, etc., can solve problems such as heavy weight, difficult processing of profile sections, and difficult processing of high-strength steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

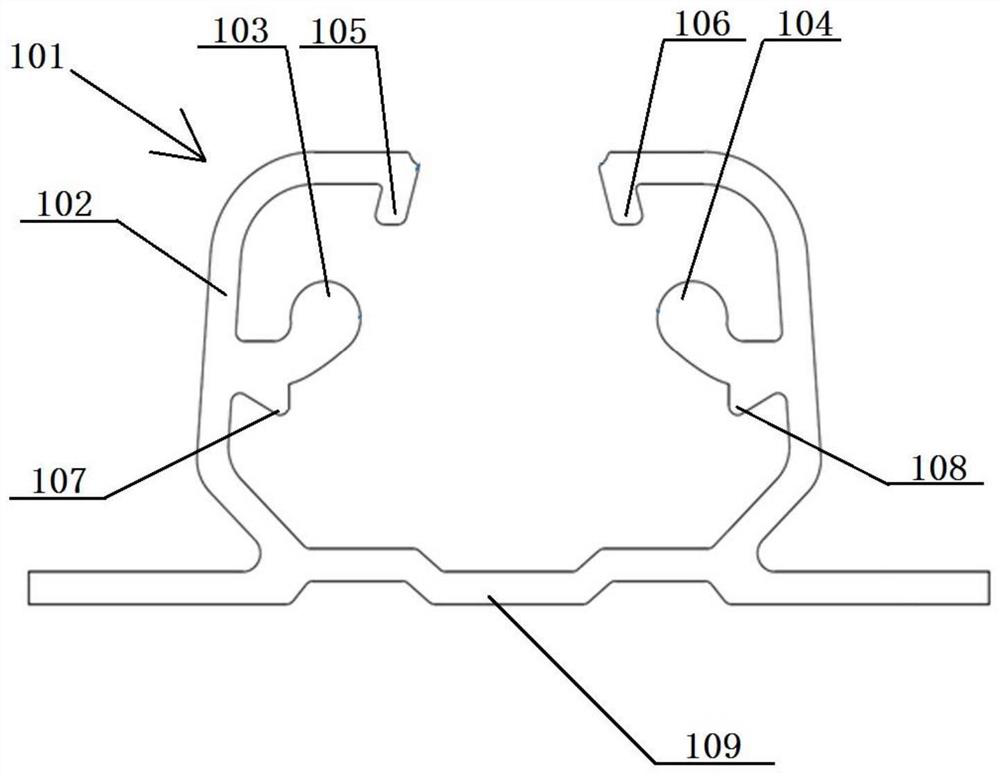

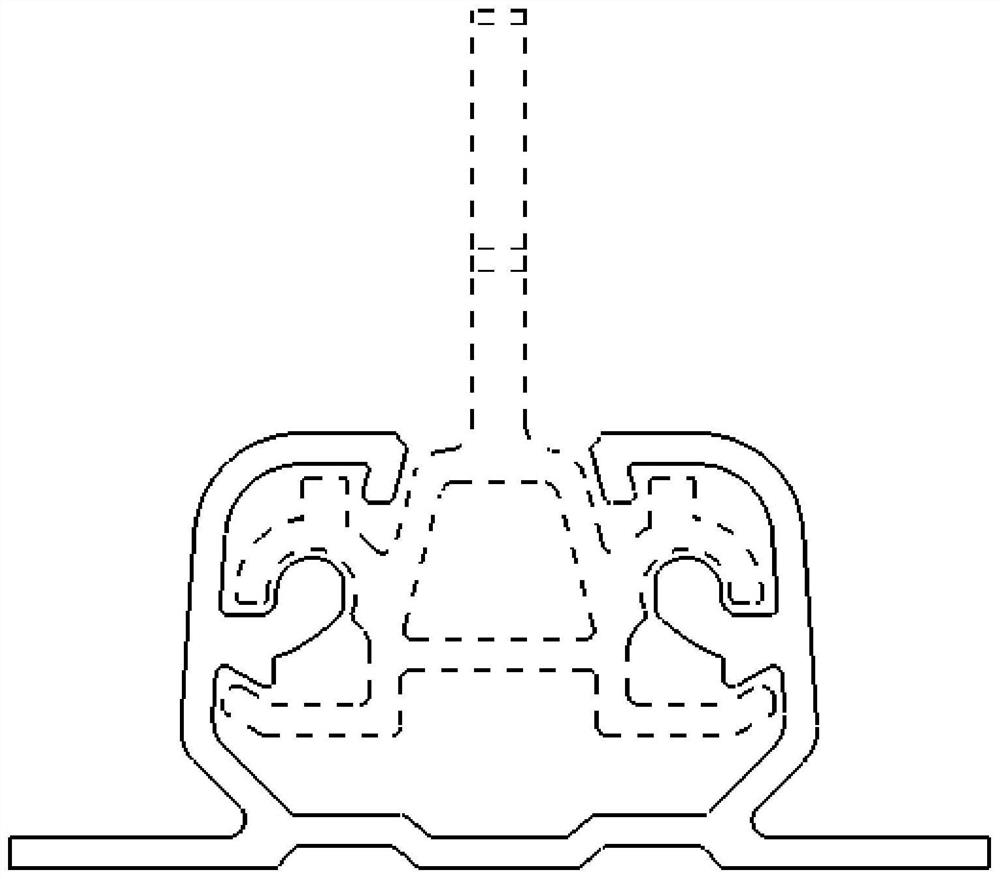

[0025] refer to Figure 1-2 , the lower rail profile for the car seat of the present invention comprises: the lower rail profile body 101, the section of the lower rail profile body 101 is a transversely symmetrical structure, and the inner positions of the side walls 102 on both sides of the lower rail profile body 101 are integrally formed There is a set of symmetrically arranged slide rail sliding brackets 103, 104, a set of symmetrically arranged anti-off hooks 105, 106 on the track and anti-off hooks 107, 108 under the track, and the slide rail sliding brackets 103, 104 are arranged on the track Between the anti-off hooks 105, 106 and the anti-off hooks 107, 108 under the track, the slide rail sliding bracket 103 cooperates with lubricating grease and a sliding sleeve to connect with the upper slide rail profile, and the bottom sides of the bottom rail profile body 101 Mounting wings 109 are arranged horizontally.

[0026] The slide rail sliding bracket 103 in the presen...

Embodiment 2

[0031] This embodiment provides a method for manufacturing a lower rail profile for an automobile seat, comprising the following steps:

[0032] Step S1: Prepare the lower rail profile body 101, the section of which is a transversely symmetrical concave structure;

[0033] Step S2: In step S1, the internal positions of the side walls 102 on both sides of the lower rail profile body 101 are integrally formed to form a set of symmetrically arranged slide rail sliding brackets 103, 104, and a set of symmetrically arranged anti-off hooks 105, 106 on the track and the track Lower anti-off hooks 107, 108, the slide rail sliding brackets 103, 104 are arranged between the anti-off hooks 105, 106 on the track and the anti-off hooks 107, 108 under the track, and the slide rail sliding brackets 103 cooperate with lubricating The grease and the sliding sleeve are docked with the upper slide rail profile, and the two sides of the bottom of the lower rail profile body 101 are horizontally p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com