Method of experimental equipment for discharging polyethylene slurry

An experimental equipment, polyethylene technology, applied in the field of polyethylene, can solve the problems of valve blockage, inability to select the type of the discharge valve, and inability to select or use the instrument equipment, and achieve the effect of continuous discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

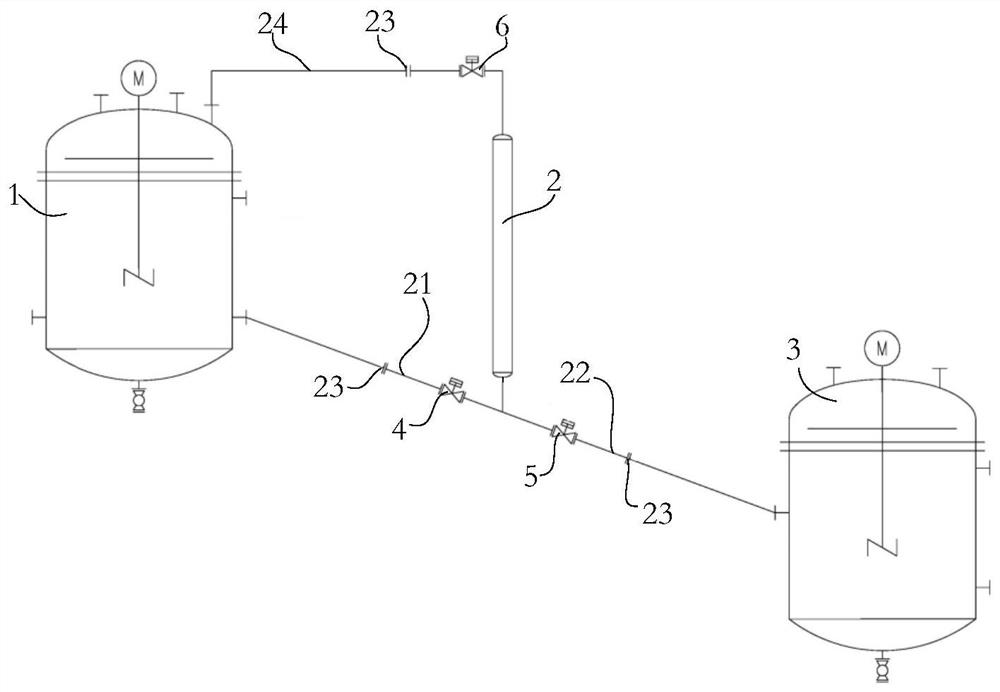

[0039] Such as figure 1 As shown, a kind of experimental equipment for polyethylene slurry discharge of the present embodiment comprises:

[0040] Polymerization reactor 1 for storing polyethylene slurry;

[0041] A discharge tank 2, the discharge tank 2 is connected to the polymerization reactor 1 through a feed pipe 21, and a first valve 4 is installed on the feed pipe 21;

[0042] A flash tank 3, the discharge tank 2 is connected to the flash tank 3 through a discharge pipe 22, and a second valve 5 is installed on the discharge pipe 22;

[0043] Wherein, the end of the feed pipe 21 and the discharge pipe 22 away from the polymerization reactor 1 extends obliquely downward; when the first valve 4 is opened, the polymerization reactor 1 will The polyethylene slurry is transported into the discharge tank 2 under the action of the potential difference; when the second valve 5 is opened, the discharge tank 2 flashes to the discharge tank 2 under the action of the pressure diff...

Embodiment 2

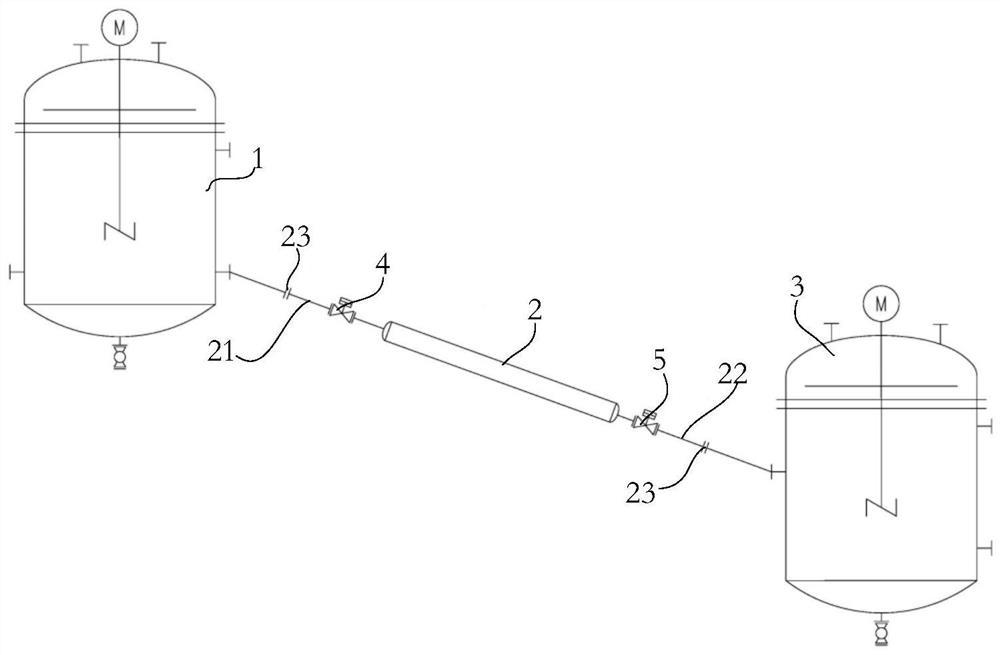

[0055] Such as figure 2 As shown, a kind of experimental equipment for polyethylene slurry discharge of the present embodiment comprises:

[0056] Polymerization reactor 1 for storing polyethylene slurry;

[0057] A discharge tank 2, the discharge tank 2 is connected to the polymerization reactor 1 through a feed pipe 21, and a first valve 4 is installed on the feed pipe 21;

[0058] A flash tank 3, the discharge tank 2 is connected to the flash tank 3 through a discharge pipe 22, and a second valve 5 is installed on the discharge pipe 22;

[0059] Wherein, the end of the feed pipe 21 and the discharge pipe 22 away from the polymerization reactor 1 extends obliquely downward; when the first valve 4 is opened, the polymerization reactor 1 will The polyethylene slurry is transported into the discharge tank 2 under the action of the potential difference; when the second valve 5 is opened, the discharge tank 2 flashes to the discharge tank 2 under the action of the pressure dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com