Continuous fixed quantity discharging device and material blending system using the same

A technology of discharge device and discharge port, which is applied in the direction of measuring device, feeding device, weighing equipment for automatic feeding/discharging, etc., can solve the problems of reducing discharge amount, unable to discharge materials smoothly and continuously, and easy deviation of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

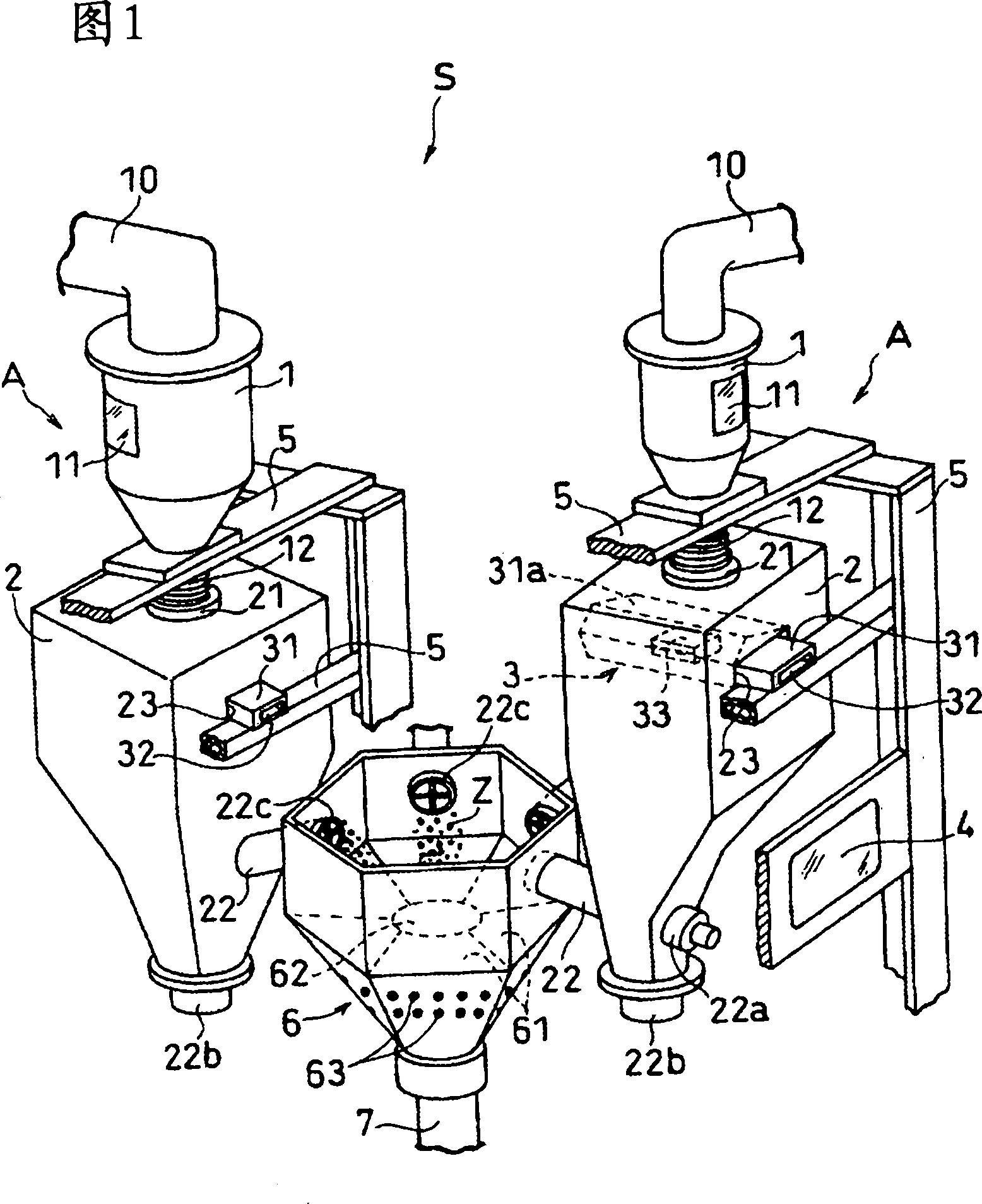

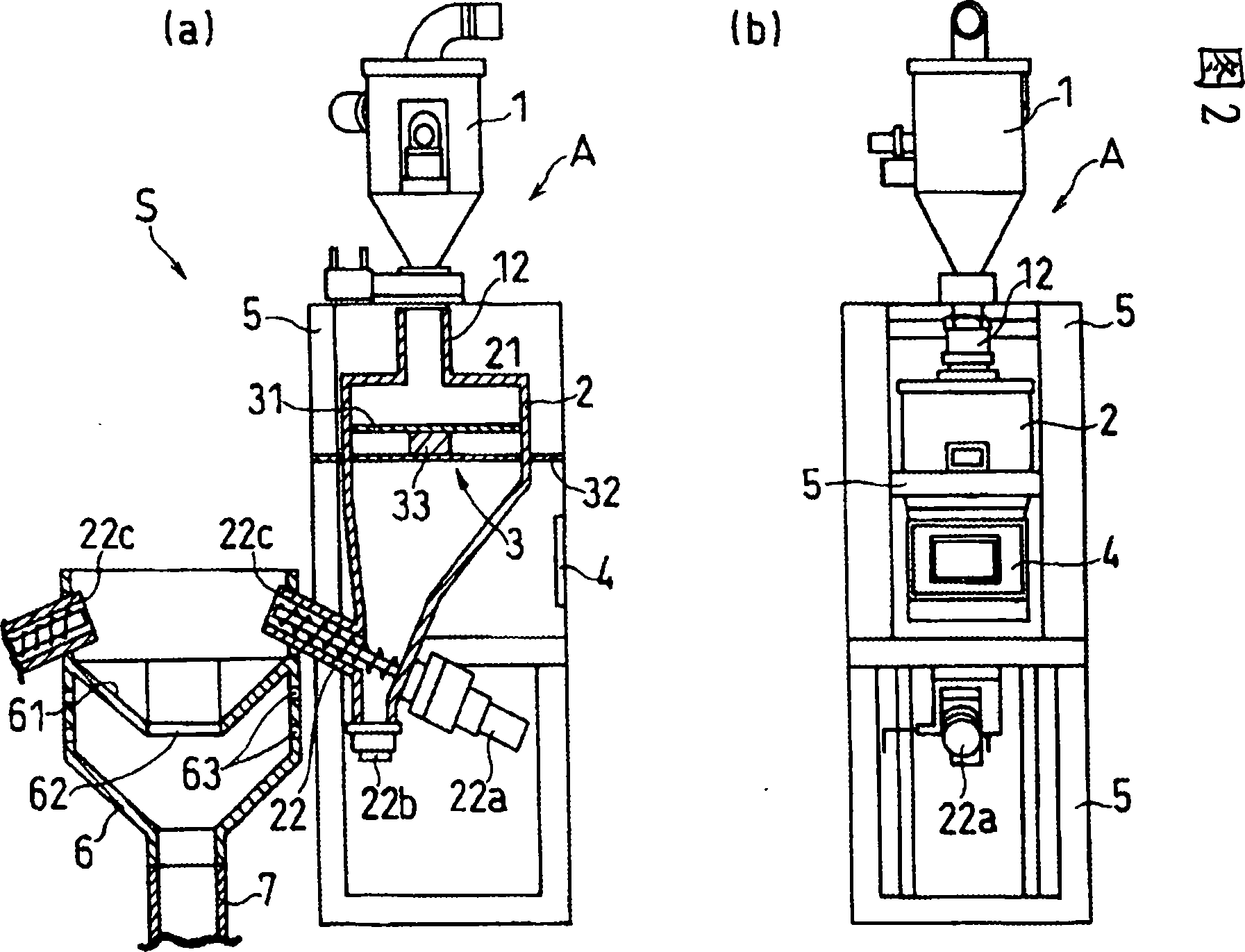

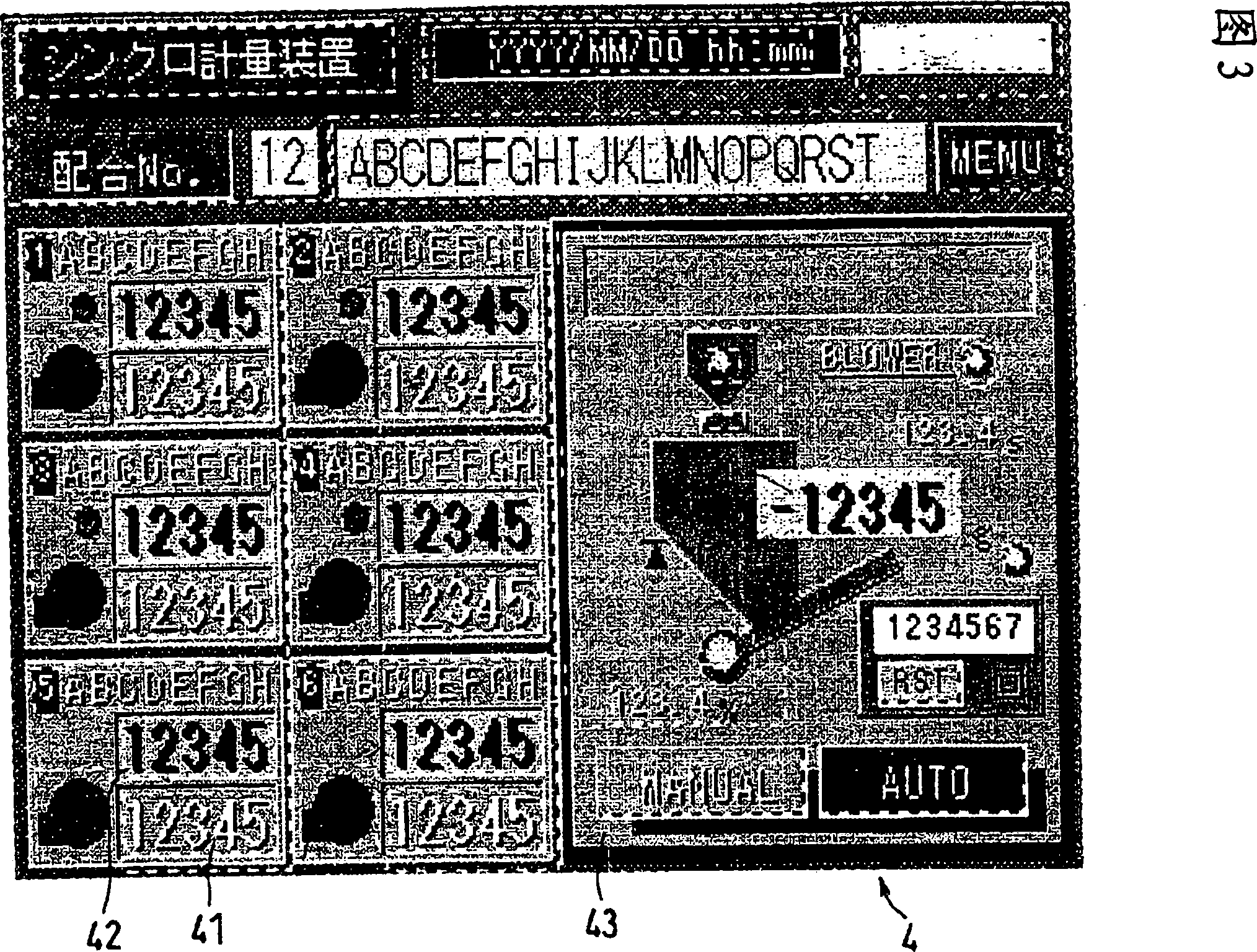

[0081] FIG. 1 is a schematic overall perspective view showing a partially cutaway state of one embodiment of a material blending system S using a continuous quantitative discharge apparatus A according to the present invention. FIG. 2 is an explanatory view schematically showing a part of FIG. (a) is a schematic vertical cross-sectional view of a partly cutaway state of FIG. 1, and FIG. 2 (b) is a schematic front view of the state of the continuous quantitative discharge device A of FIG. 1 seen from the control unit.

[0082] First, the continuous quantitative discharge device A according to the present invention will be described.

[0083] The continuous quantitative discharge device A is composed of a material retention tank 1, a material storage container 2, a load cell type mass measuring unit 3, a control unit 4 and an outer frame frame 5,

[0084] The material retention tank 1 is used to retain the material Z continuously supplied by the supply member 10;

[0085] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com