Pneumatic reversing jolt compacting packing machine

A technology of compacting and chartering, which is applied in the field of silo equipment for vibrating materials and silo equipment, can solve the problems of insufficient packing, unreasonable silo structure, and inability to continuously discharge materials, etc., to achieve high production efficiency and effective The effect of using the bagging space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

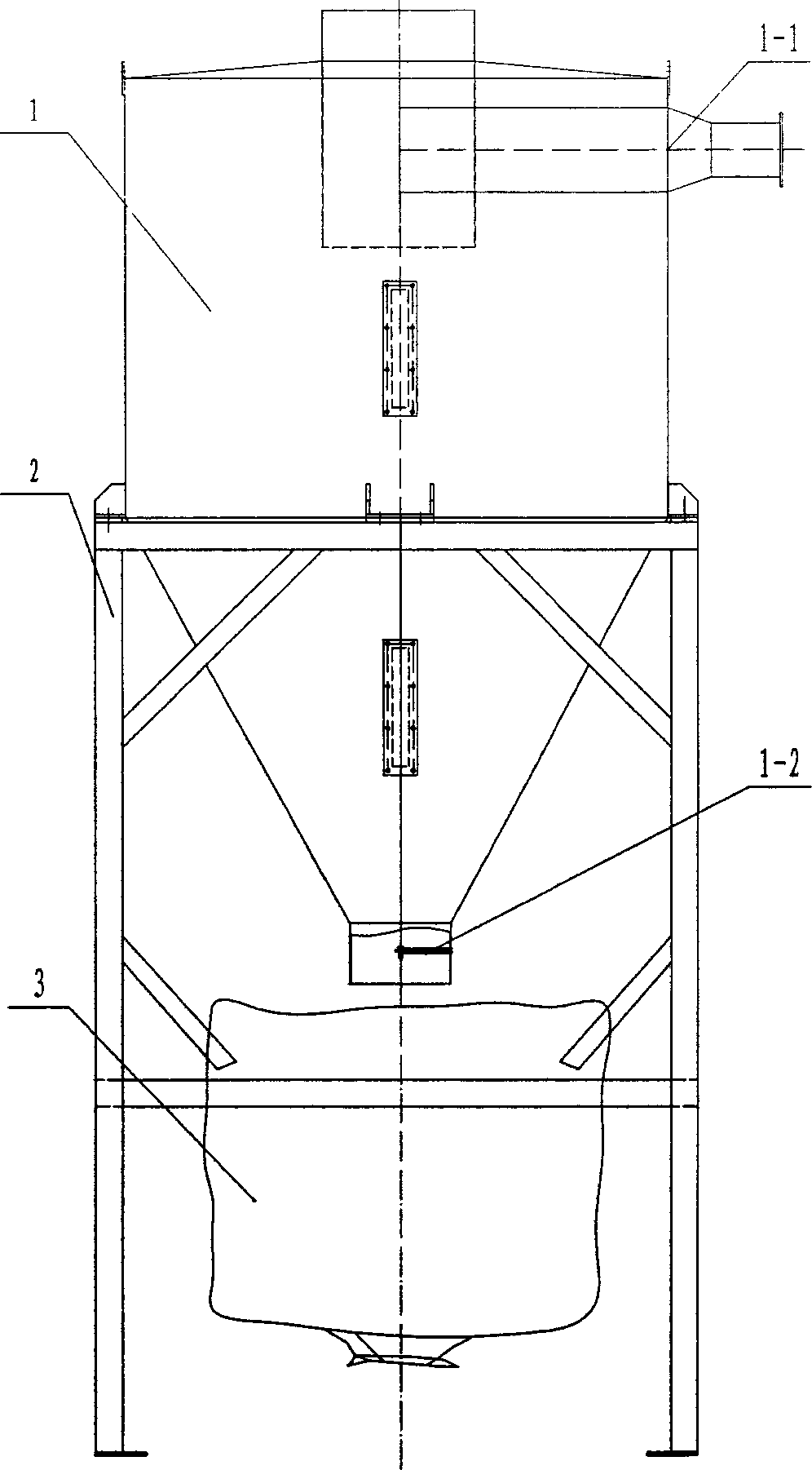

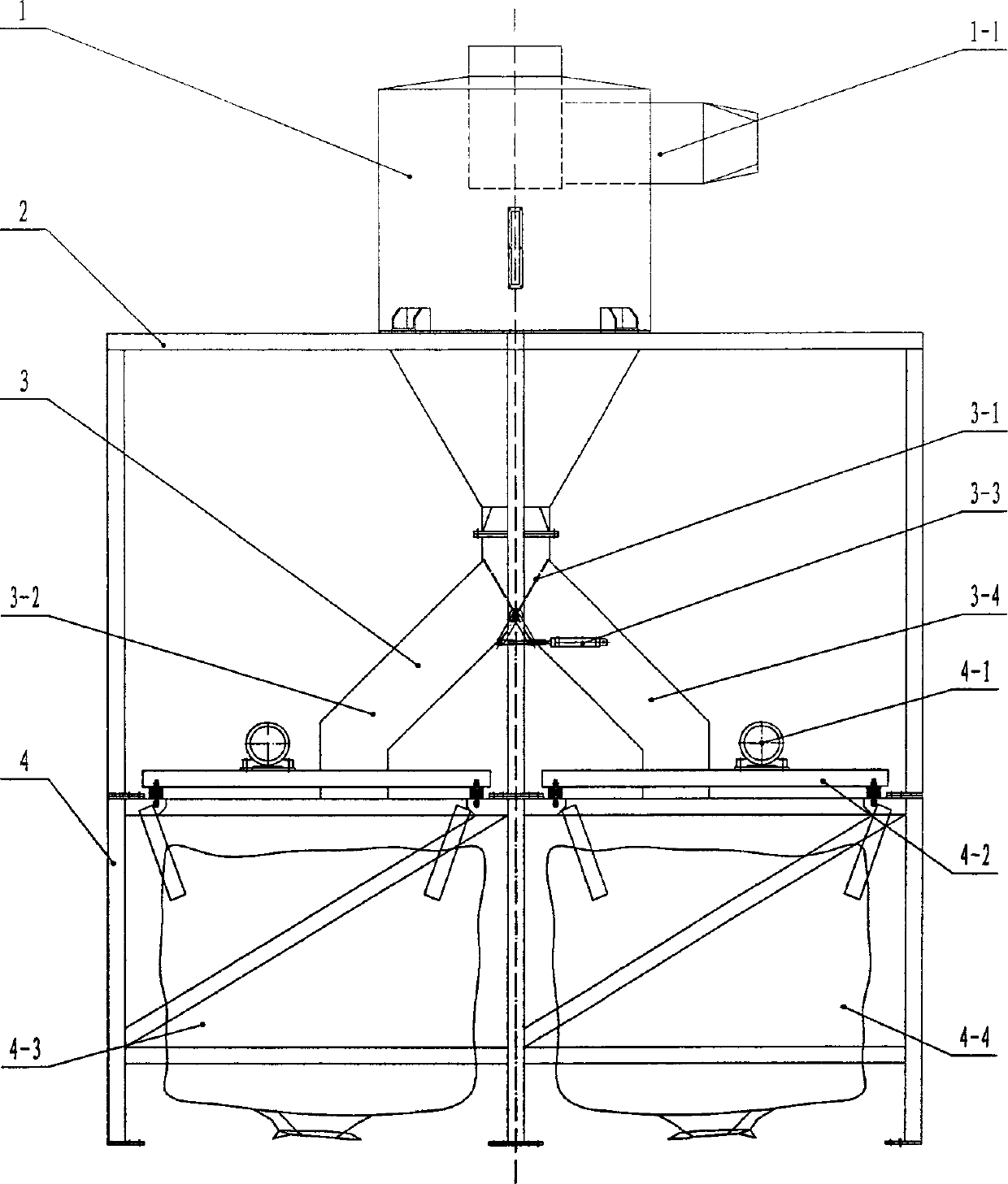

[0011] exist figure 2 Among them, the silo cylinder (1) is installed on the upper frame (2), and there is a feed inlet (1-1) on the upper right of the silo cylinder (1), and the sub The material box (3), the sealing plate (3-1) is set in the material distribution box (3) to divide the material distribution box (3) into the left box (3-2) and the right box (3-4) , the sealing plate (3-1) stretches out of the material distribution box (3) and is connected with the cylinder (3-3), and the cylinder (3-3) drives the swing of the sealing plate (3-1), and the upper frame (2) Connect with lower frame (4), platform (4-2) is housed above lower frame (4), vibration motor (4-1) is installed above platform (4-2), hangs below platform (4-2) Pack bags (4-3)(4-4).

[0012] The working principle is: the material enters the silo cylinder (1) from the feed port (1-1), and the cylinder (3-3) on the distribution box (3) pushes the sealing plate (3-1) to the right Above the box body (3-4), the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com