Magnetoelectric cyclic regeneration reduction oil purifier

A cyclic regeneration and oil purifier technology, applied in mixers, mixers with rotary stirring devices, filter circuits, etc., can solve the problem of inability to obtain clear and transparent industrial oils, no regeneration and reduction effect, and industrial oils that are too acidic. and other problems, to achieve the effect of being conducive to reuse, avoiding the phenomenon of pressurization, and improving transparency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

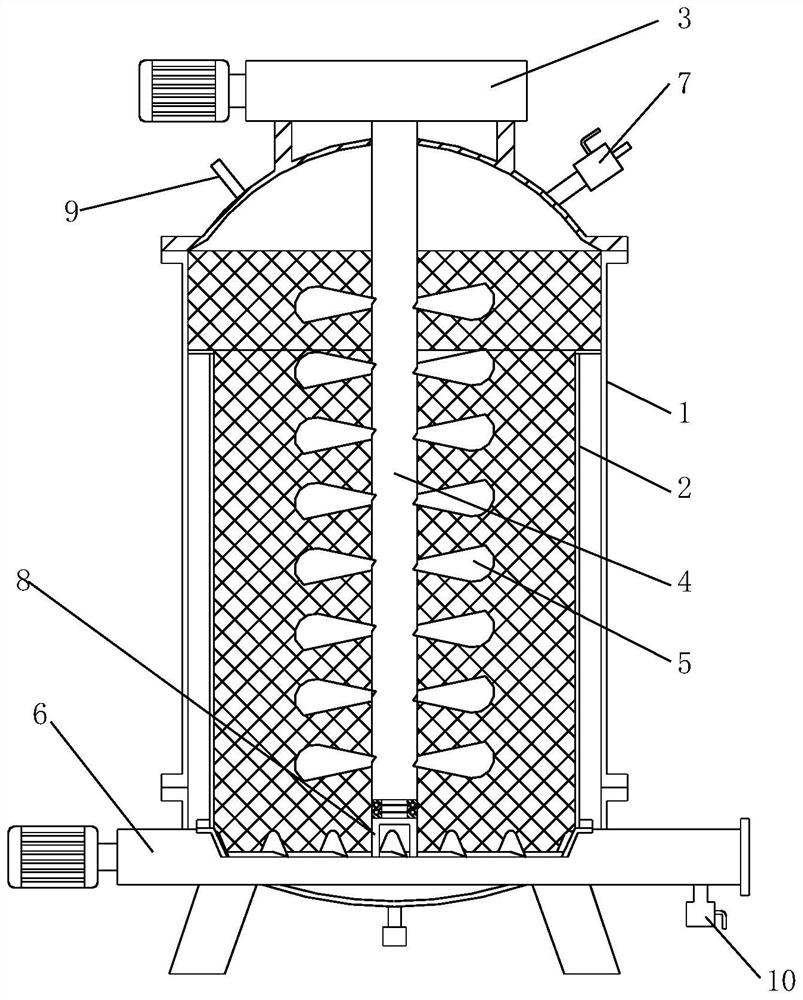

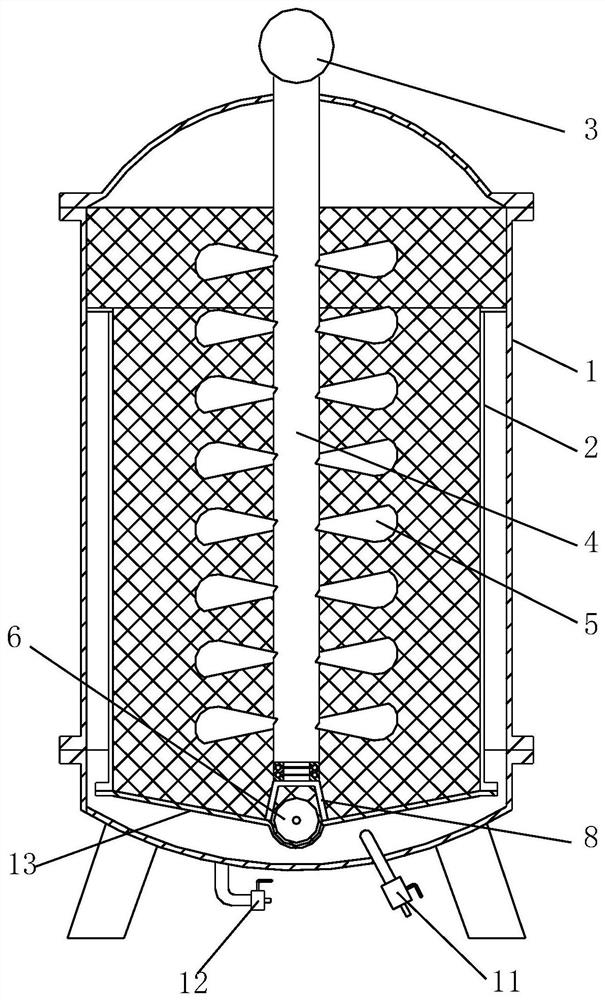

[0019] See figure 1 , figure 2 , a magnetoelectric cycle regeneration reduction oil purifier, including a tank shell 1, a rotating shaft 4, a gear motor 3, a screw conveyor 6, a feed port 7, an oil inlet 9, a filter barrel 2, a bracket 8, and an oil outlet 11. The discharge port 12, the filter barrel 2 is fixed inside the tank shell 1, the filter barrel 2 is used to hold the filter material, the middle of the tank shell 1 is vertically provided with a rotating shaft 4, the rotating shaft 4 is driven by the reduction motor 3, and the rotating shaft 4 is fixed with a number of rotating blades 5, the bottom of the rotating shaft 4 is connected with the bracket 8 through a thrust bearing, the bracket 8 is fixed on the screw conveyor 6, the screw co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com