Gelatin hollow capsule with anti-crosslinking effect and preparation method thereof

A hollow capsule and cross-linking technology, which is applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, capsule delivery, etc., can solve the problems that gelatin empty capsules are prone to cross-linking reactions, etc., and achieve obvious resistance Effect of cross-linking, reduction of risk of non-equivalence, effect of reducing degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

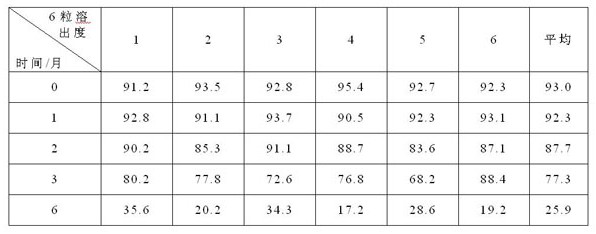

Embodiment 1

[0024] Add 1,000 parts of 1,000 parts of purified water to a sol tank heated to 73°C, stir to dissolve, and pump at -0.05 MPa. After vacuuming for 15 minutes, use a 350-mesh filter to filter the glue into the glue barrel, add an appropriate amount of food coloring and titanium dioxide, and adjust the viscosity to the process requirements with purified water, and let it stand for heat preservation to remove air bubbles; the glue is stable for 5 hours after removing air bubbles and then used in the automatic capsule production line Production, after the mold is glued, it is automatically pushed into the drying kiln for drying, and the capsules that have passed the drying weight loss are demoulded, cut and fitted. The unqualified capsules are picked out by the automatic capsule sorting machine and then packaged, inspected, and put into storage.

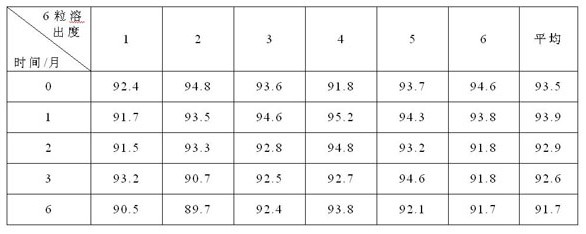

Embodiment 2

[0026] Add 1000 parts of 220 B Loomg gelatin, 7 parts of polyethylene glycol 6000, 10 parts of ammonium bicarbonate, 4 parts of DLTP and 4 parts of BHT into 3500 parts of purified water, which has been heated to 80 ℃, and stir to dissolve. After vacuuming at -0.05MPa for 15 minutes, use a 350-mesh filter to filter the glue into the glue barrel, add an appropriate amount of food coloring and titanium dioxide, and adjust the viscosity to the process requirements with purified water, and let it stand for heat preservation to remove air bubbles; the glue is stable for 7 hours after removing air bubbles and then used Fully automatic capsule production line, after the mold is glued, it is automatically pushed into the drying kiln for drying, and the capsules that pass the drying weight loss are demoulded, cut and fitted. storage.

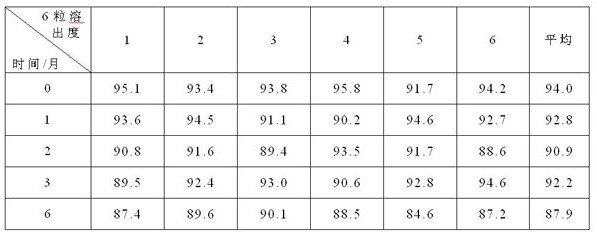

Embodiment 3

[0028] Add 1000 parts of gelatin, 4 parts of polyethylene glycol 4000, 2 parts of glycerin, 10 parts of sodium hydroxide and 10 parts of TDPA into 3500 parts of purified water heated to 83 ° C in a sol tank, stir to dissolve, After vacuuming at -0.05MPa for 17 minutes, use a 350-mesh filter to filter the glue into the glue barrel, add an appropriate amount of food coloring and titanium dioxide, and adjust the viscosity to the process requirements with purified water, and let it stand for heat preservation to remove air bubbles; the glue is stable for 6 hours after removing air bubbles and then used Fully automatic capsule production line, after the mold is glued, it is automatically pushed into the drying kiln for drying, and the capsules that pass the drying weight loss are demoulded, cut and fitted. storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com