Comprehensive concentrated soup stock based on enzymolysis reaction process and preparation process thereof

A technology for concentrated soup stock and preparation process, which is applied in the field of food seasonings, can solve the problems of the influence of the nutrient substance content of the concentrated soup stock, the easy loss of nutrients, and the decrease of amino acid content, and achieves a taste and smell that is mellow and strong, rich in flavor, and maintains flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

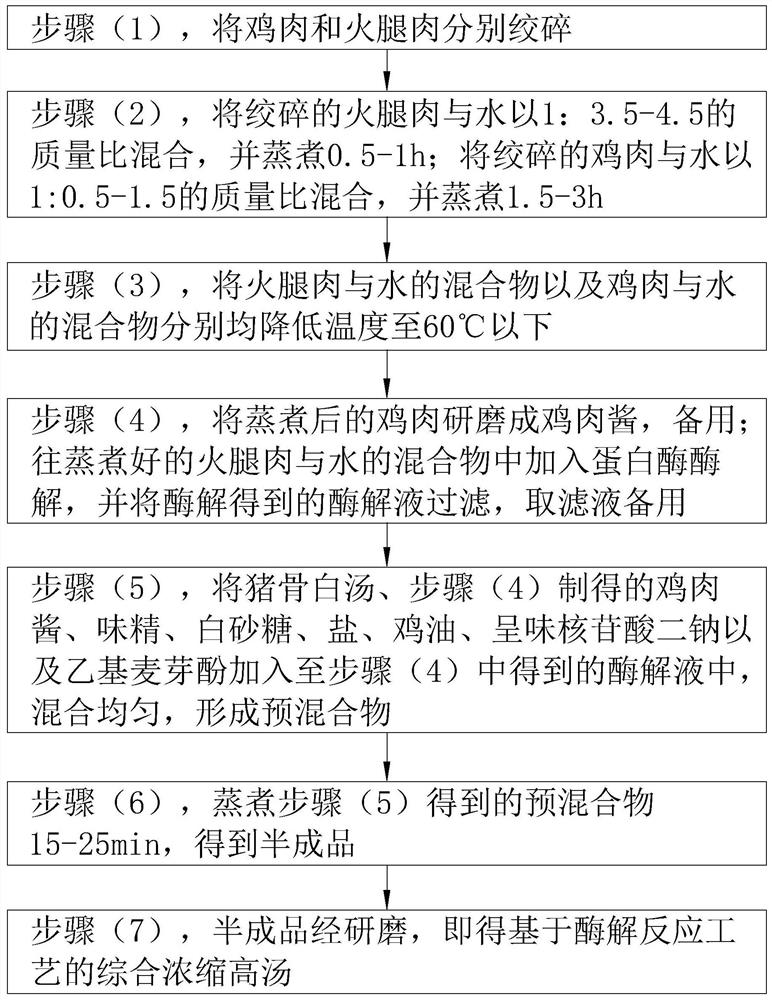

[0065] refer to figure 1 , a preparation process of comprehensive concentrated stock based on enzymolysis reaction process comprises the following steps:

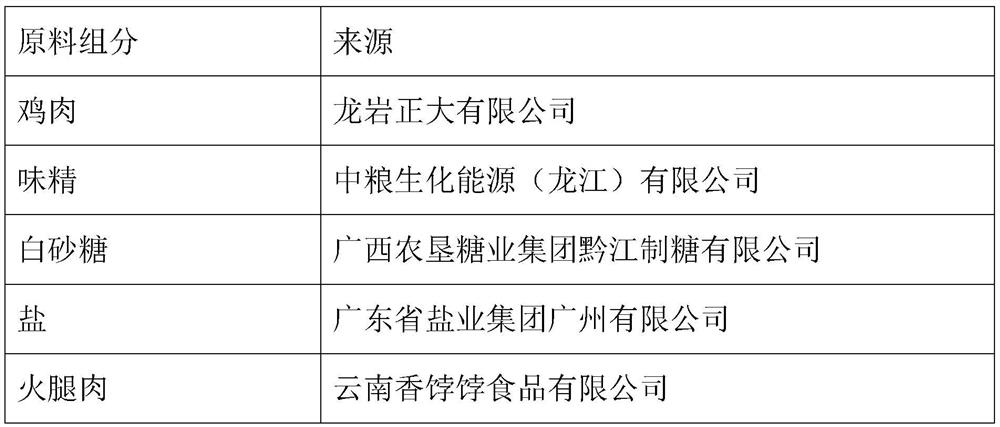

[0066] In step (1), pull the chicken and ham from the cold storage to the thawing place to thaw, wash with clean water to remove foreign matter and impurities, and put them into a meat grinder to grind.

[0067] In step (2), the ground ham and water in step (1) are placed in a cooking pot with a mass ratio of 1:3.5, and the temperature is raised to 95° C. while stirring, and the heat preservation is cooked for 1 hour; the step The ground chicken and water in (1) were placed in a cooking pot with a mass ratio of 1:0.5, and the temperature was raised to 95°C while stirring, and kept for cooking for 3 hours.

[0068] In step (3), the cooling water is turned on to lower the temperature of the cooked ham and chicken to 58° C. respectively.

[0069] In step (4), put the steamed and cooled chicken into a colloid mill and grind i...

Embodiment 2

[0076] The difference with embodiment 1 is:

[0077] In step (2), the mass ratio of ham to water is 1:4.5, the cooking temperature is 102°C, and the cooking time is 0.5h; the mass ratio of chicken to water is 1:1.5, the cooking temperature is 102°C, and the cooking time is 1.5 h. h.

[0078] In step (3), the temperature of the cooked ham and chicken is respectively lowered to 55°C.

[0079] In step (4), the temperature of the controlled enzymolysis is 60° C., and the time of the controlled enzymolysis is 1.5 h.

[0080] In step (6), raise the temperature of the reactor to 95° C., and cook for 15 minutes.

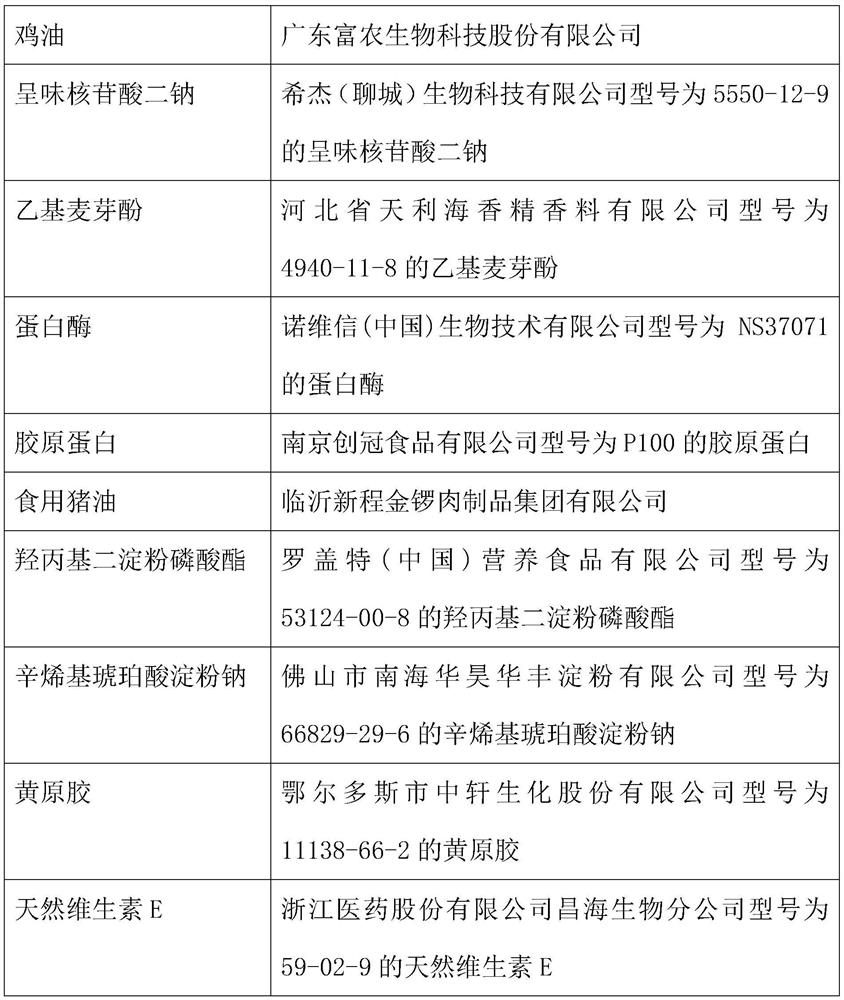

[0081] The raw material components and contents of the comprehensive concentrated broth based on the enzymatic hydrolysis reaction process are shown in Table 2, and the unit of each component content in Table 2 is kg.

Embodiment 3

[0083] The difference with embodiment 1 is:

[0084] In step (2), the mass ratio of ham to water is 1:3.5, the cooking temperature is 98°C, and the cooking time is 1h; the mass ratio of chicken to water is 1:0.5, the cooking temperature is 98°C, and the cooking time is 3h.

[0085] In step (3), the temperature of the cooked ham and chicken is respectively lowered to 55°C.

[0086] In step (4), the enzymolysis solution is filtered by using a sieve with a mesh size of 50 mesh.

[0087] The raw material components and contents of the comprehensive concentrated broth based on the enzymatic hydrolysis reaction process are shown in Table 2, and the unit of each component content in Table 2 is kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com