Drum-type microwave sterilizer

A microwave sterilization and drum-type technology, which is applied in food science and other fields, can solve the problems of changing taste and taste, wasting energy, and taking hours or even longer to complete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

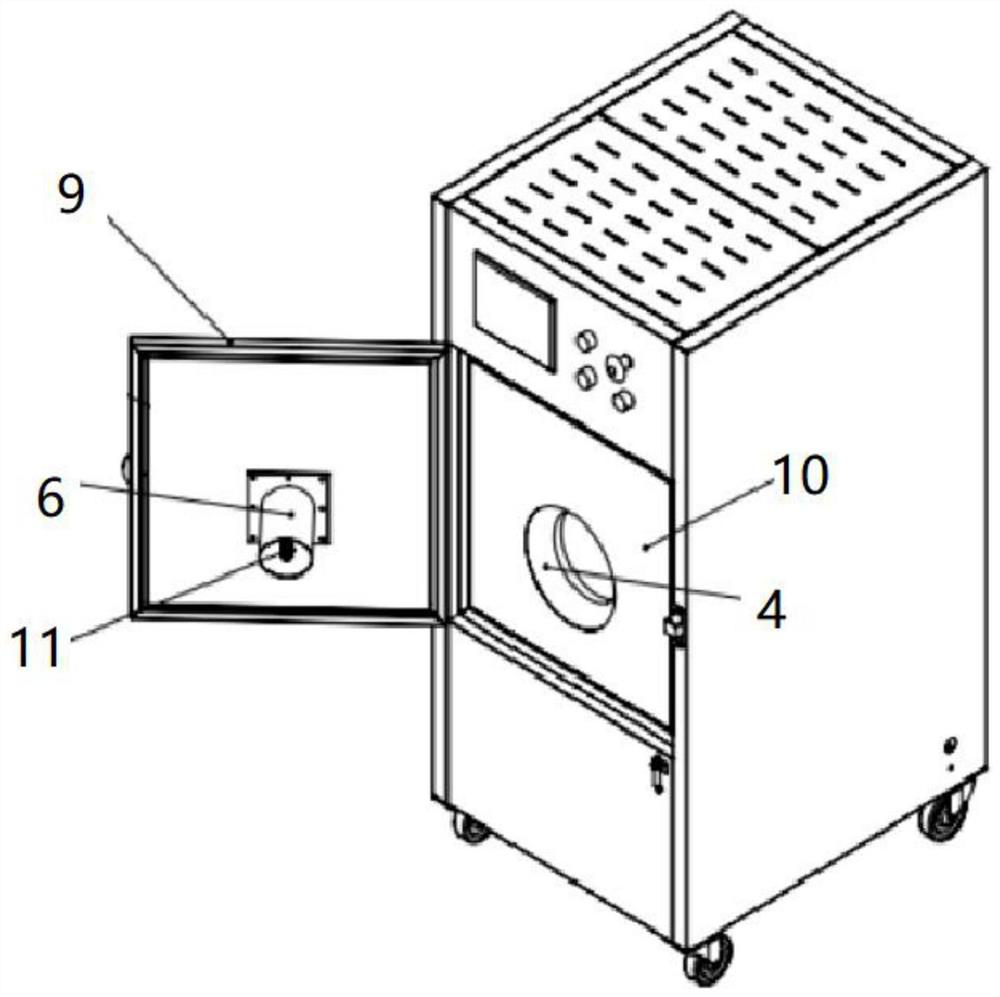

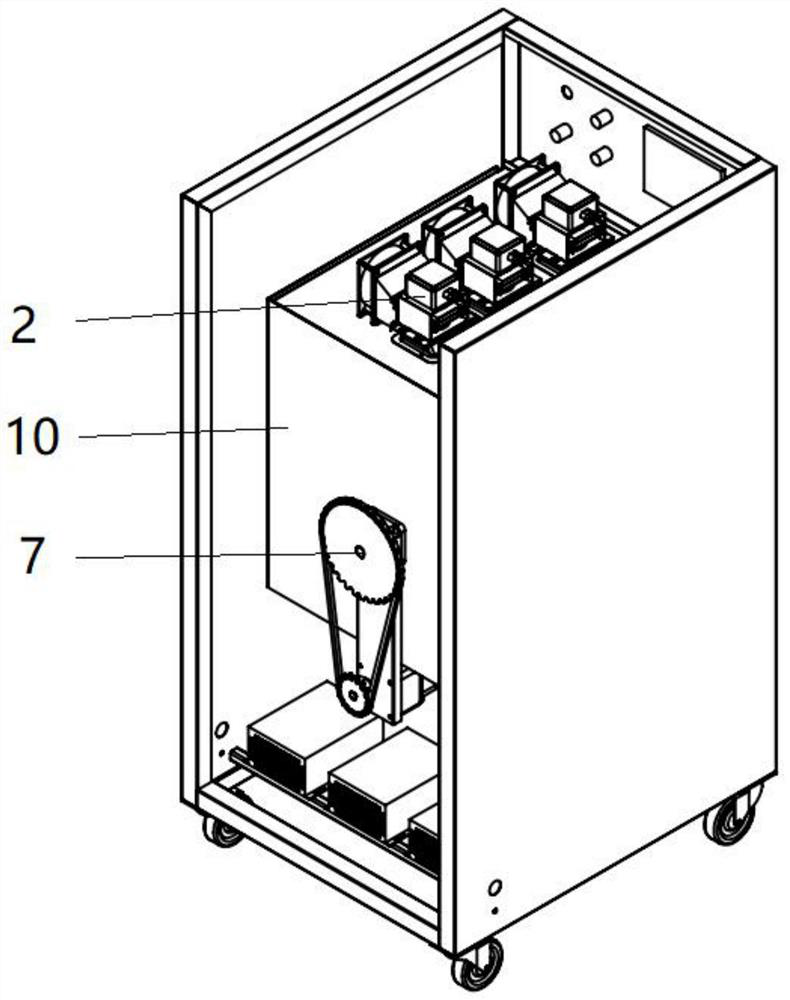

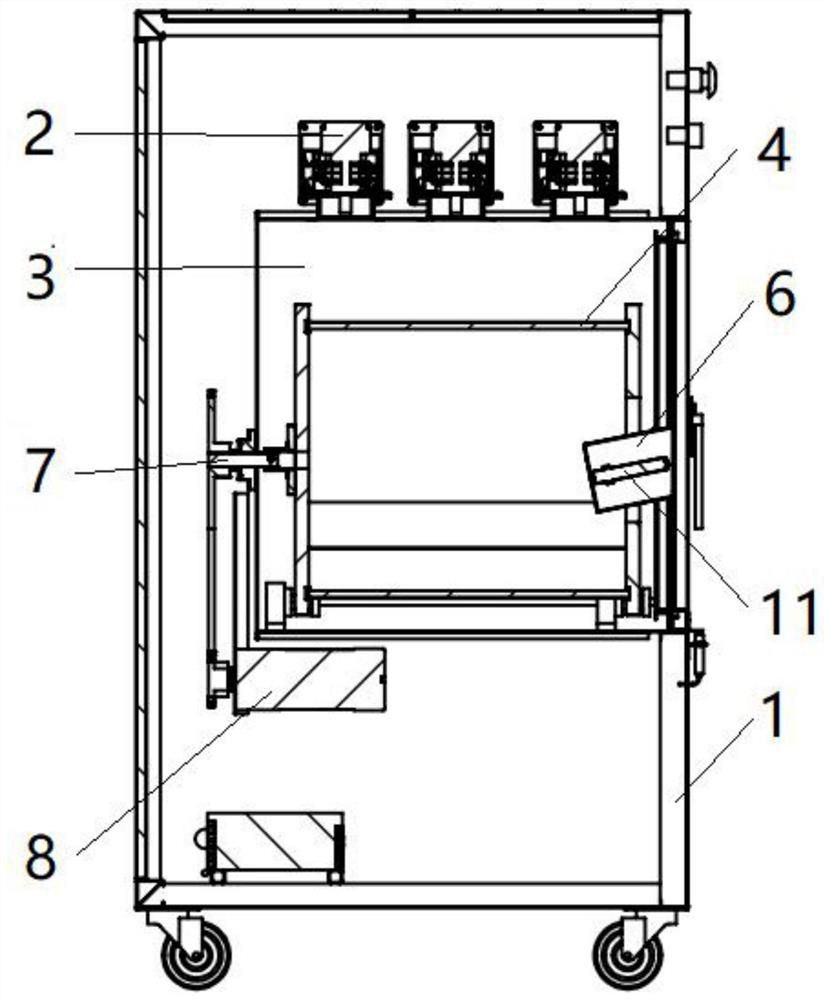

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0022] Such as Figure 1-4 As shown, a drum-type microwave sterilizer includes a case 1, which is provided with a microwave emission system 2 for sterilizing products and a sterilization cavity 3 for accommodating products. The microwave emission system 2 is arranged in the sterilizer Outside the bacterial cavity 3, the microwave transmitting system 2 includes a microwave transmitter and a microwave waveguide, the microwave waveguide connects the microwave transmitter and the sterilizing cavity 3, the microwave emitted by the microwave transmitter is introduced into the sterilizing cavity 3 through the microwave waveguide, and the sterilizing cavity 3 A vertical drum 4 is provided to uniformly sterilize the product, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com