Preparation method of low-bitterness rice protein peptide solid beverage

A rice protein peptide and solid beverage technology, applied in the field of solid beverage processing, can solve the problems of product flavor impact and failure to meet consumer needs well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

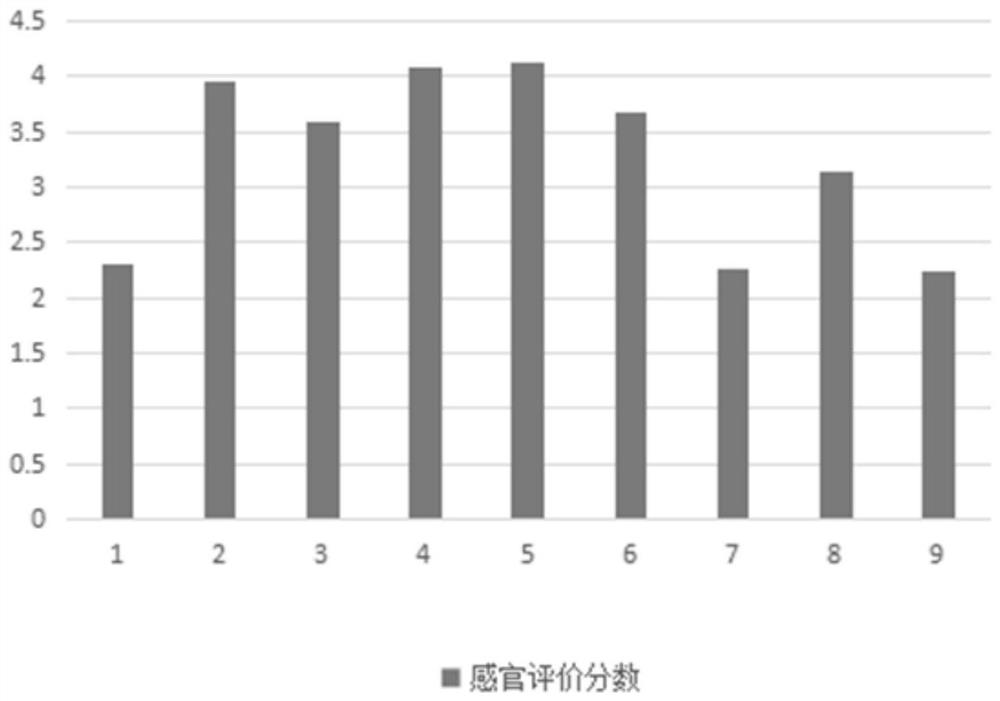

Image

Examples

Embodiment 1

[0029] Example 1: A kind of method of low bitterness rice protein peptide solid drink (original taste)

[0030] In terms of parts by mass, the following raw materials are weighed:

[0031] Rice protein peptide powder: 93.5 parts;

[0032] Material Ⅰ: 2 parts of glycine, 1.5 parts of L-alanine, 0.5 parts of GABA;

[0033] Material Ⅱ: 1.5 parts of citric acid, 1 part of steviol glycoside;

[0034] (1) Primary mixing: fully mix the material Ⅰ (2x parts of glycine, 1.5 parts of L-alanine, 0.5 parts of GABA) weighed in proportion by a mixer, control the mixing temperature at 5-10°C, and the mixing rate At 1000~1500r / min, mix for 10~30min to get the mixture ①;

[0035] (4) Secondary mixing: put 1.5 parts of citric acid and 1 part of steviol glycoside into the mixing material ① in two times, and mix thoroughly. ~1500r / min, mix for 10~30min, get the mixture ②;

[0036] (3) Mixing materials three times to prepare solid beverages: weigh 93 parts of rice protein peptide powder acc...

Embodiment 2

[0041] Embodiment 2: a kind of method of low bitterness rice protein peptide solid drink (orange flavor)

[0042] The steps of this method are as follows:

[0043] A method of rice protein peptide solid beverage (orange flavor) with low bitterness, is characterized in that, by mass parts, comprises following raw material:

[0044] Rice protein peptide powder: 80.5 parts;

[0045] Material Ⅰ: 1 part of glycine, 1 part of L-alanine, 0.5 part of GABA;

[0046] Material Ⅱ: 1 part of citric acid, 0.5 part of steviol glycoside;

[0047] 10 parts of maltodextrin, 5 parts of erythritol;

[0048] Orange food flavor: 0.5 parts.

[0049] (1) Primary mixing: fully mix the weighed material Ⅰ and material Ⅱ through a mixer, control the mixing temperature at 5-10°C, and mix at a mixing rate of 1000-1500r / min for 10-30min to obtain a mixed Material ①;

[0050](4) Secondary mixing: 0.5 part of essence, 5 parts of erythritol, and 10 parts of maltodextrin that were weighed in proportion ...

Embodiment 3

[0056] Embodiment 3: a kind of method of low bitterness rice protein peptide solid drink (strawberry flavor)

[0057] The steps of this method are as follows:

[0058] A method for a low-bitter rice protein peptide solid beverage (strawberry flavor), characterized in that, in parts by mass, the method comprises the following raw materials:

[0059] Rice protein peptide powder: 58.8 servings;

[0060] Material I: 1 part of glycine, 1 part of L-alanine, 0.5 part of GABA;

[0061] Material II: 1.5 parts of citric acid, 0.5 part of stevioside;

[0062] Blueberry powder: 10 servings;

[0063] 10 parts of erythritol;

[0064] Isomaltooligosaccharide: 5 parts;

[0065] Malttooligosaccharides: 5 servings;

[0066] Fructooligosaccharides: 3 servings;

[0067] Inulin: 3 servings;

[0068] Red beet powder: 0.3 servings;

[0069] Strawberry-flavored flavor: 0.4 servings.

[0070] (1) One-time mixing: fully mix the weighed material I and material II through a mixer, control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com