Ultrasonic-microwave synergistic egg white liquid sterilization process

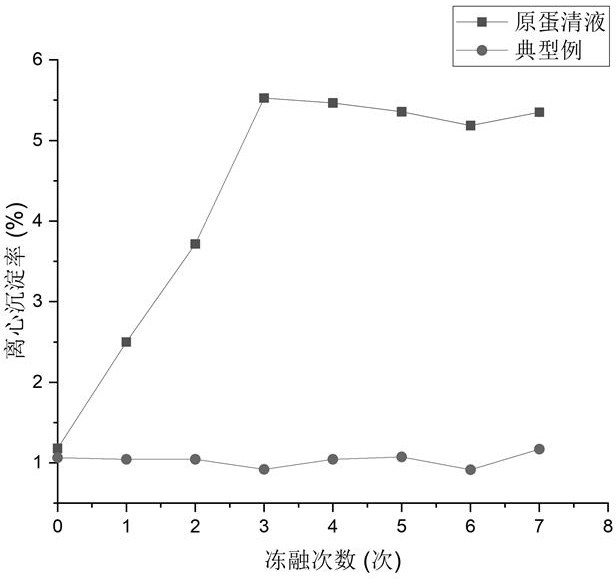

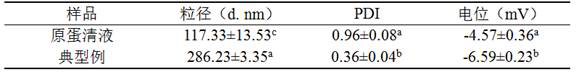

A technology of egg white liquid and microwave, which is applied in the field of egg white liquid sterilization technology, can solve the problems of limited application, affecting the functional properties of egg white liquid, protein denaturation and aggregation, etc., and achieves good freeze-thaw stability, excellent freeze-thaw stability, and foaming and the effect of improving the gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

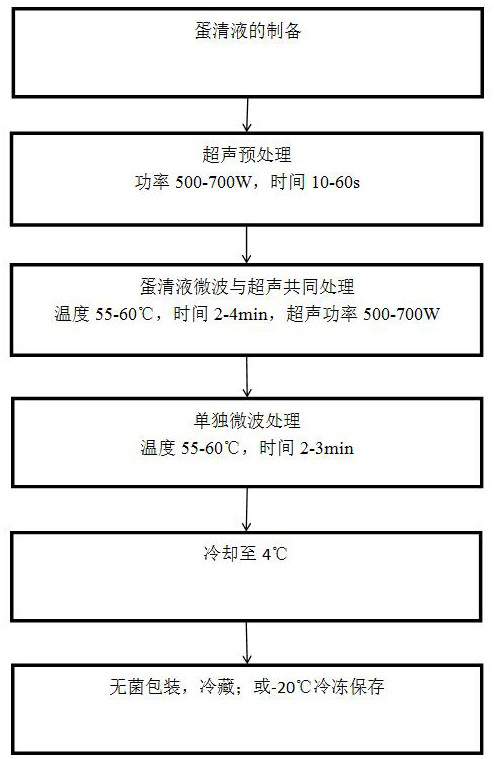

Method used

Image

Examples

Embodiment 1

[0022] The present embodiment carries out ultrasonic-microwave synergistic egg white liquid sterilization according to the following steps:

[0023] Step 1. Fresh eggs are washed, sterilized on the surface of the eggshell, beaten, separated from the yolk, and removed from the frenulum to obtain a spare egg white;

[0024] Step 2. Ultrasonic treatment is performed on the egg white liquid obtained in Step 1, and the ultrasonic power is controlled to be 700W for 30s;

[0025] Step 3. The egg white liquid obtained in step 2 is subjected to microwave and ultrasonic treatment, the temperature is controlled at 55°C, the time is 4min, and the ultrasonic power is 700W;

[0026] Step 4. Microwave the egg white solution obtained in Step 3. The temperature is controlled at 55° C. and the time is 3 minutes;

[0027] Step 5, rapidly cooling the sterilized egg white liquid obtained in step 4 to 4°C;

[0028] Step 6. Aseptically pack the sterilized egg white liquid obtained in Step 5, and r...

Embodiment 2

[0037] The present embodiment carries out ultrasonic-microwave synergistic egg white liquid sterilization according to the following steps:

[0038] Step 1. Fresh eggs are washed, sterilized on the surface of the eggshell, beaten, separated from the yolk, and removed from the frenulum to obtain a spare egg white;

[0039] Step 2. Ultrasonic treatment is performed on the egg white liquid obtained in Step 1, and the ultrasonic power is controlled to be 600W, and the time is 30s;

[0040] Step 3. The egg white liquid obtained in Step 2 is subjected to microwave and ultrasonic treatment, the temperature is controlled at 57°C, the time is 3 minutes, and the ultrasonic power is 600W;

[0041] Step 4. Microwave the egg white solution obtained in Step 3. The temperature is controlled at 57° C. and the time is 3 minutes;

[0042] Step 5, rapidly cooling the sterilized egg white liquid obtained in step 4 to 4°C;

[0043] Step 6. Aseptically package the sterilized egg white solution ob...

Embodiment 3

[0045] The present embodiment carries out ultrasonic-microwave synergistic egg white liquid sterilization according to the following steps:

[0046] Step 1. Fresh eggs are washed, sterilized on the surface of the eggshell, beaten, separated from the yolk, and removed from the frenulum to obtain a spare egg white;

[0047] Step 2. Ultrasonic treatment is performed on the egg white liquid obtained in Step 1, and the ultrasonic power is controlled to be 600W, and the time is 30s;

[0048] Step 3. The egg white liquid obtained in Step 2 is subjected to microwave and ultrasonic treatment, the temperature is controlled at 59°C, the time is 2.5min, and the ultrasonic power is 600W;

[0049] Step 4. Microwave the egg white solution obtained in Step 3. Control the temperature at 59°C for 2 minutes;

[0050] Step 5, rapidly cooling the sterilized egg white liquid obtained in step 4 to 4°C;

[0051] Step 6. Aseptically package the sterilized egg white solution obtained in Step 5, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com