Single-layer microstrip dual-polarization transmission array antenna and manufacturing method

A manufacturing method and a dual-polarization technology, which are applied to antenna unit combinations, antennas, and antenna components with different polarization directions, can solve the problems of rising manufacturing costs and increasing the complexity of dual-polarization planar transmission array antennas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

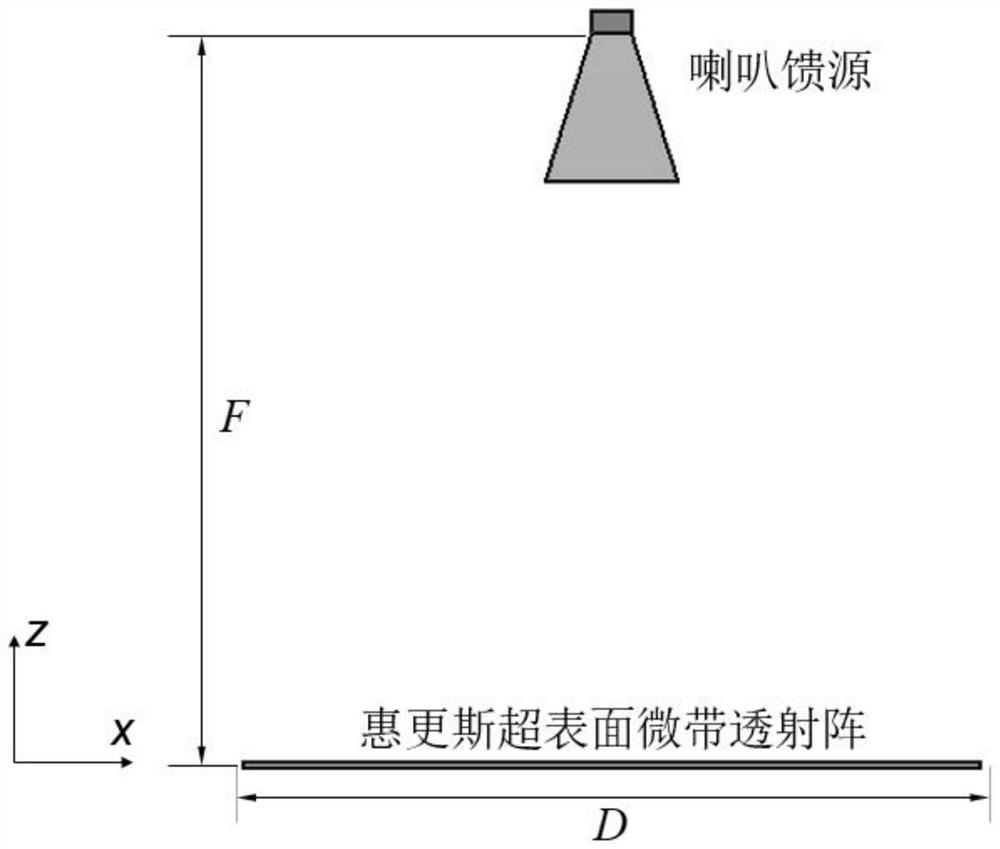

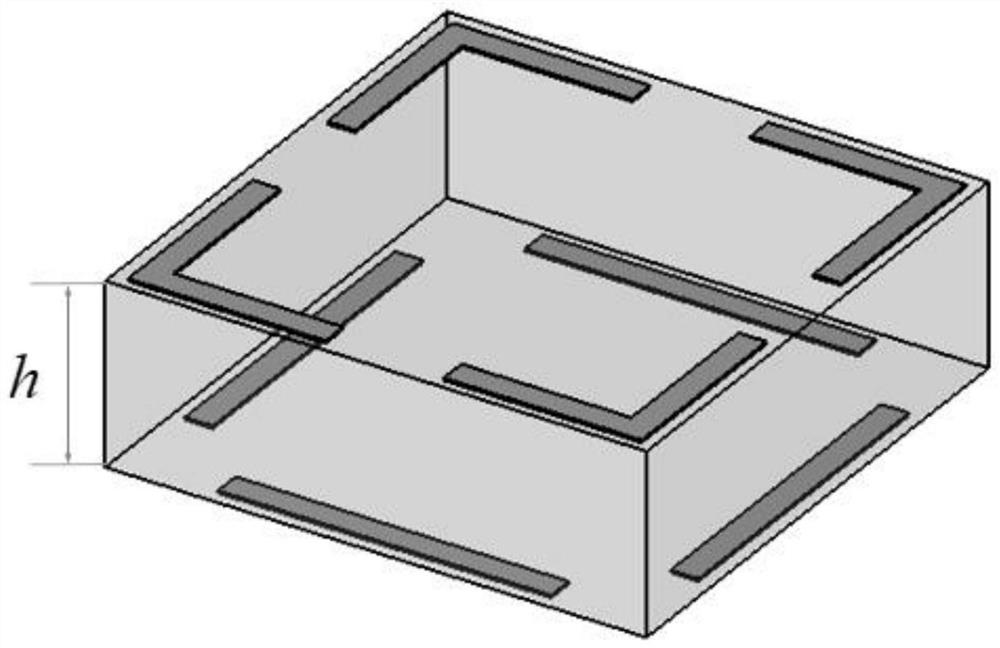

[0051] Such as figure 1As shown, a single-layer microstrip dual-polarized transmission array antenna based on Huygens metasurface, the antenna is composed of a horn feed and a Huygens metasurface microstrip dual-polarization transmission array; the horn feed consists of a waveguide and a horn The opening is formed; the Huygens metasurface microstrip dual-polarization transmission array is composed of N*N symmetrical metasurface transmission units.

[0052] Preferably, the waveguide is a standard waveguide BJ260, and the diameter of the waveguide is a*b=8.636*4.318mm 2 , the opening diameter of the horn is A*B=31*22mm 2 , The overall height of the horn is L=42mm.

[0053] Preferably, the aperture of the Huygens metasurface microstrip dual-polarization transmission array is D*D, in order to effectively form a radiation beam with high gain and low sidelobe, the aperture D of the Huygens metasurface microstrip dual-polarization transmission array *D should be greater than 10λ ...

Embodiment 2

[0061] A method for manufacturing a single-layer microstrip dual-polarized transmission array antenna based on a Huygens metasurface, comprising the following steps:

[0062] Step 1: According to the phase distribution optimization, obtain the aperture phase distribution of the single-layer microstrip dual-polarization transmission array antenna of the Huygens metasurface: firstly, select and determine the single-layer microstrip dual-polarization transmission array antenna of the Huygens metasurface The initial parameters include the horn feed position F (the distance between the horn opening and the Huygens metasurface microstrip dual-polarization transmission array), the central operating frequency f of the Huygens metasurface microstrip dual-polarization transmission array 0 , the aperture size D of the Huygens metasurface microstrip dual-polarization transmission array, and the number of metasurface transmission units In order to form a symmetrical uniform beam, N is gen...

Embodiment 3

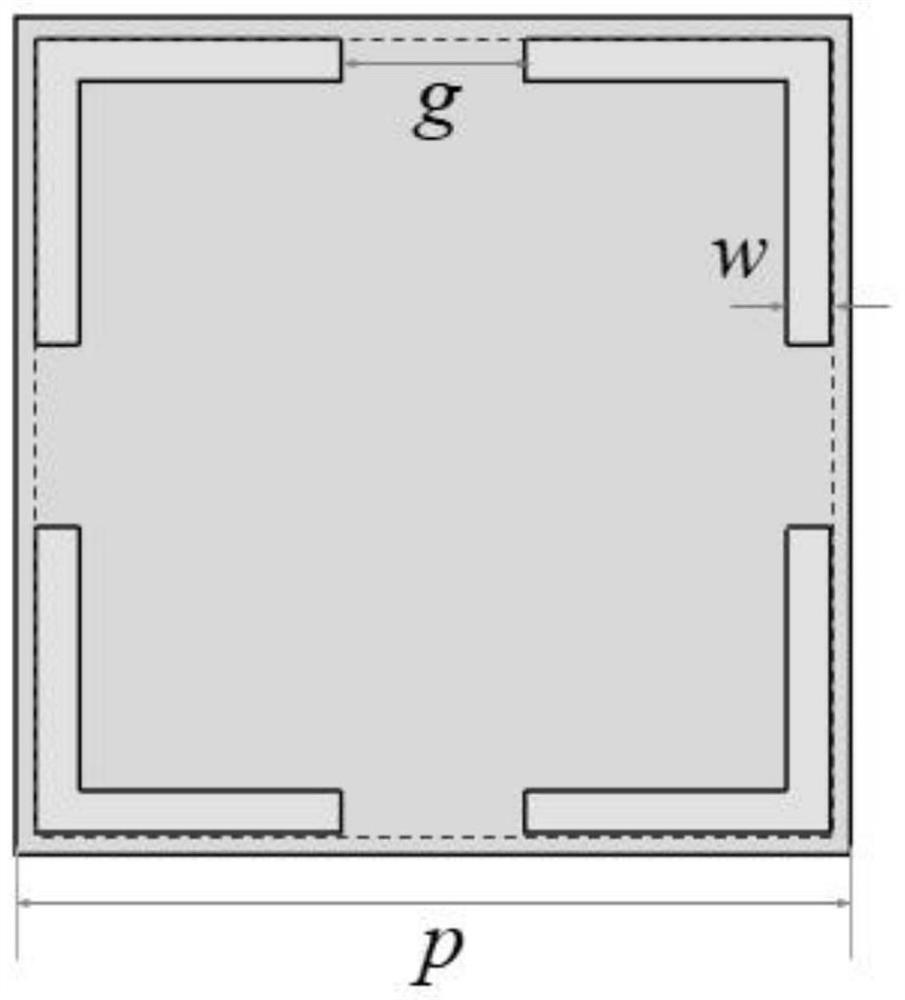

[0076] The advantage of the Huygens supersurface microstrip dual-polarization transmission array antenna designed by the present invention is that the dual-polarization function has low side lobe and high gain, and the single-layer dielectric plate design has no through hole, light weight, low cost and Easy to assemble and integrate. The structural parameters of the central transmission unit of the metasurface microstrip dual-polarization transmission array are p = 5mm, w = 0.2mm, s = 4.8mm, g = 1mm, l = 3.4mm, the topological structure of other units see Figure 7-8 ; Central operating frequency f of the dual-polarized transmission array antenna of the present invention 0 =28GHz, N=33, D=165mm, F=159mm.

[0077] For verifying the correctness of the design method of the present invention, as Figure 9-10 As shown, given the Huygens metasurface microstrip dual-polarized transmission array at the center frequency f 0 = The simulated normalized radiation pattern at 28GHz, it c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com