Guide apparatus for substrate transfer

A technology of guiding devices and substrates, applied in the direction of packaging, conveyors, conveyor objects, etc., can solve problems such as damage, swing or bending, and poor G of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, description will be made with reference to the accompanying drawings of preferred embodiments of the present invention that can concretely realize the problems to be solved above. In describing the present embodiment, the same names and the same reference numerals are used for the same configurations, and additional description thereof will be omitted.

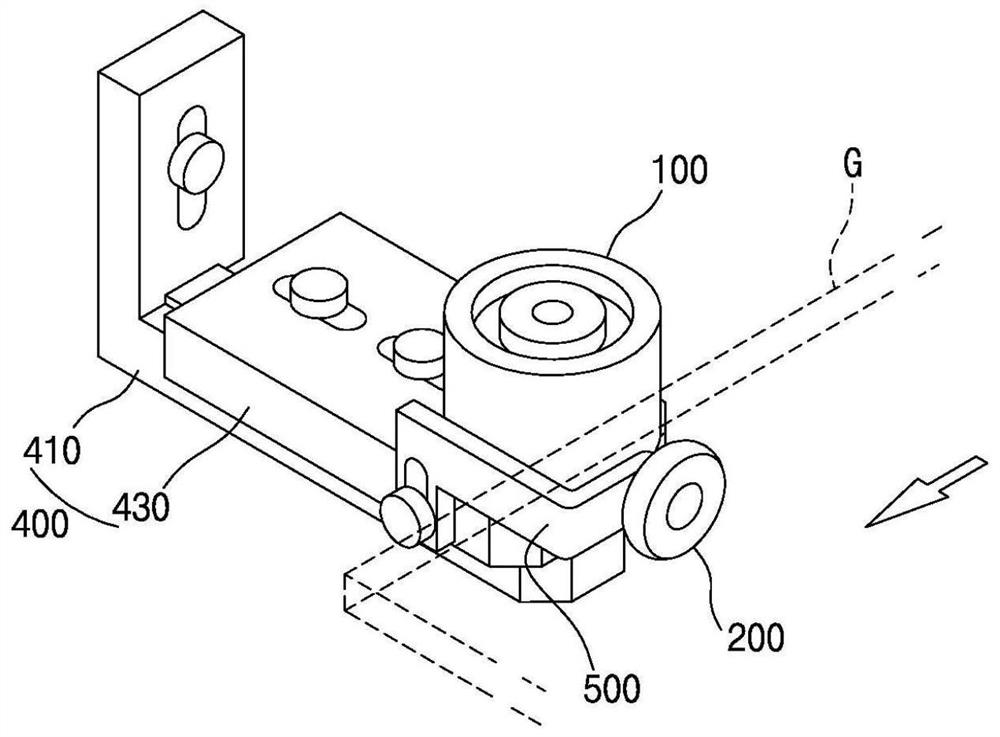

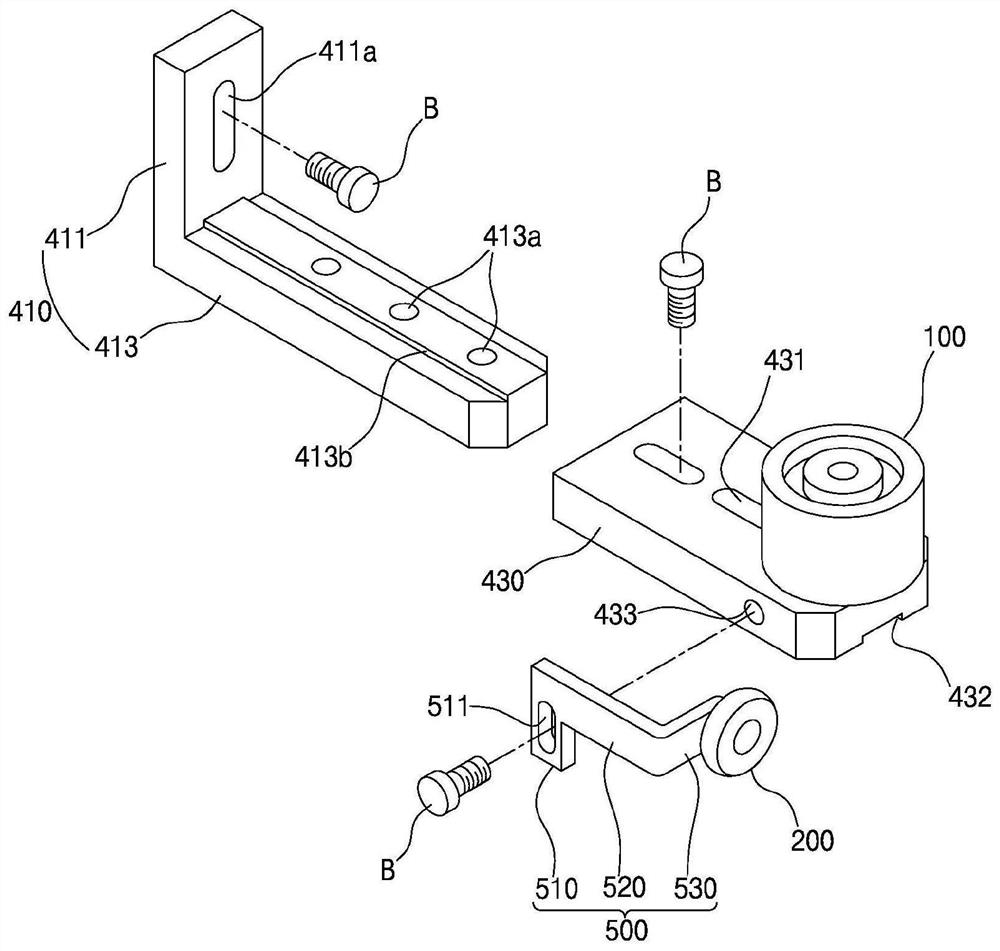

[0032] figure 2 is a perspective view of a substrate transfer guide device according to a first embodiment of the present invention, image 3 yes figure 2 An exploded perspective view of the substrate transfer guide shown.

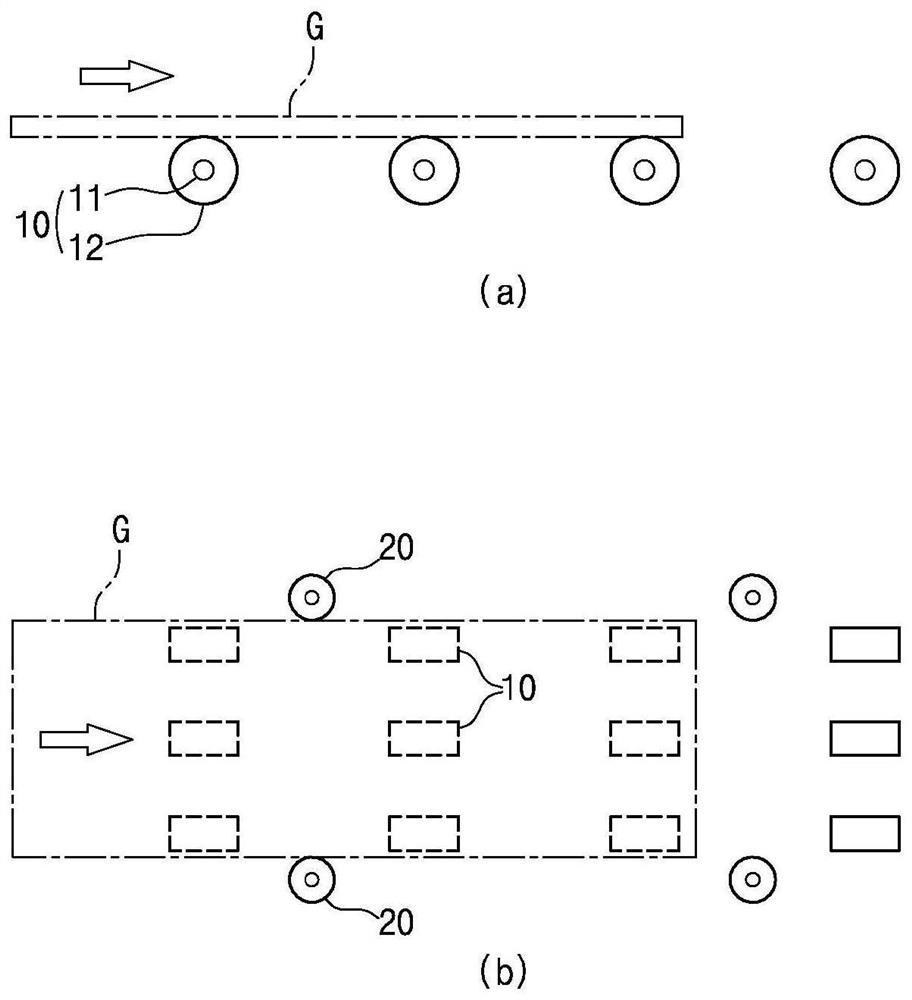

[0033] The substrate conveying guide device according to the present invention may be provided as a pair disposed opposite to each other at both end portions of the substrate G.

[0034] In addition, a plurality of the pair of substrate transfer guide devices may be arranged at intervals along the longitudinal direction of the substrate G to be transferred.

[0035] refer to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com