Railroad bridge top beam detection system and method

A bridge and top beam technology, applied in the field of railway bridge top beam detection system, can solve problems such as rail fracture, railway outage, lifting height, and rail stress increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

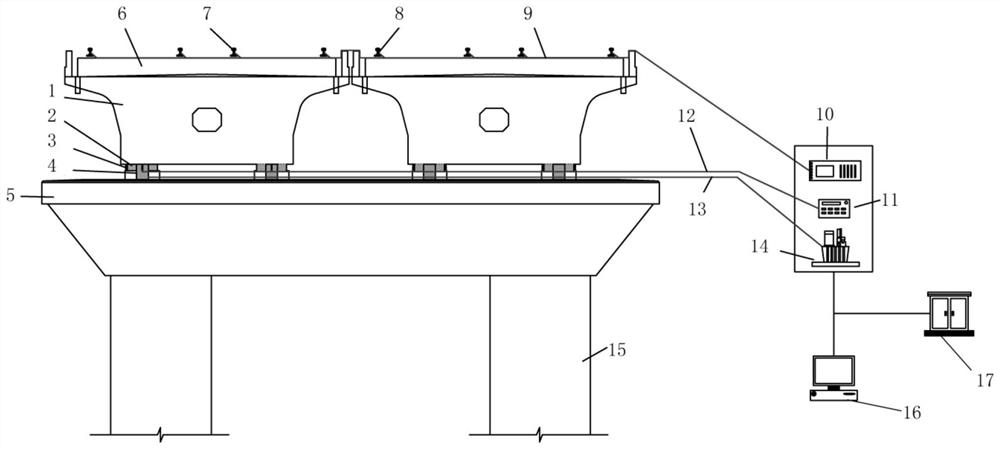

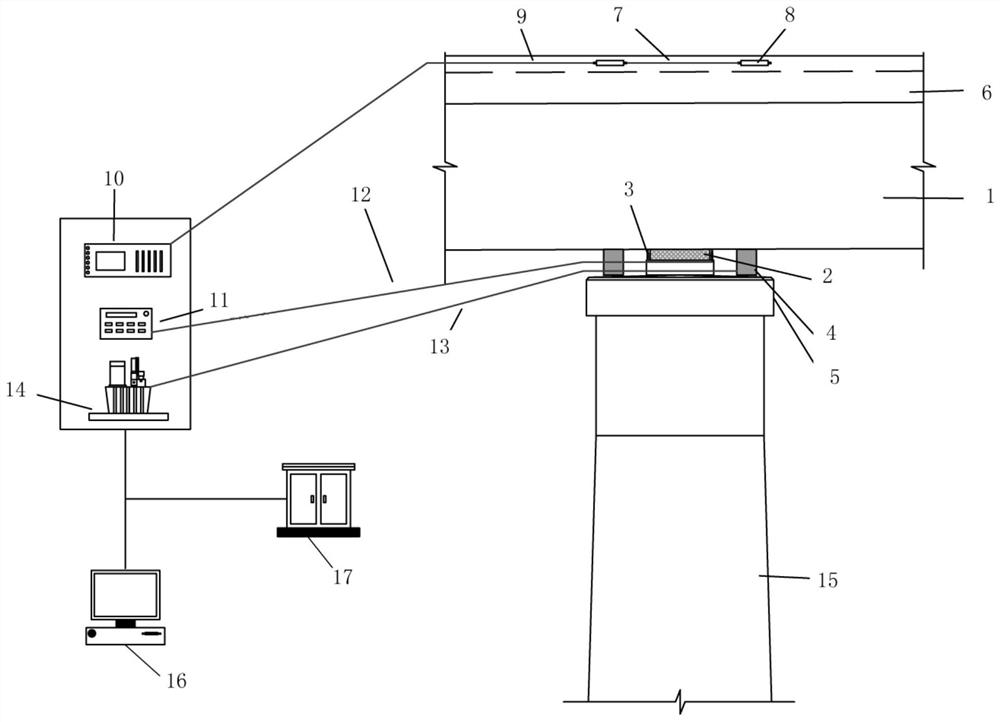

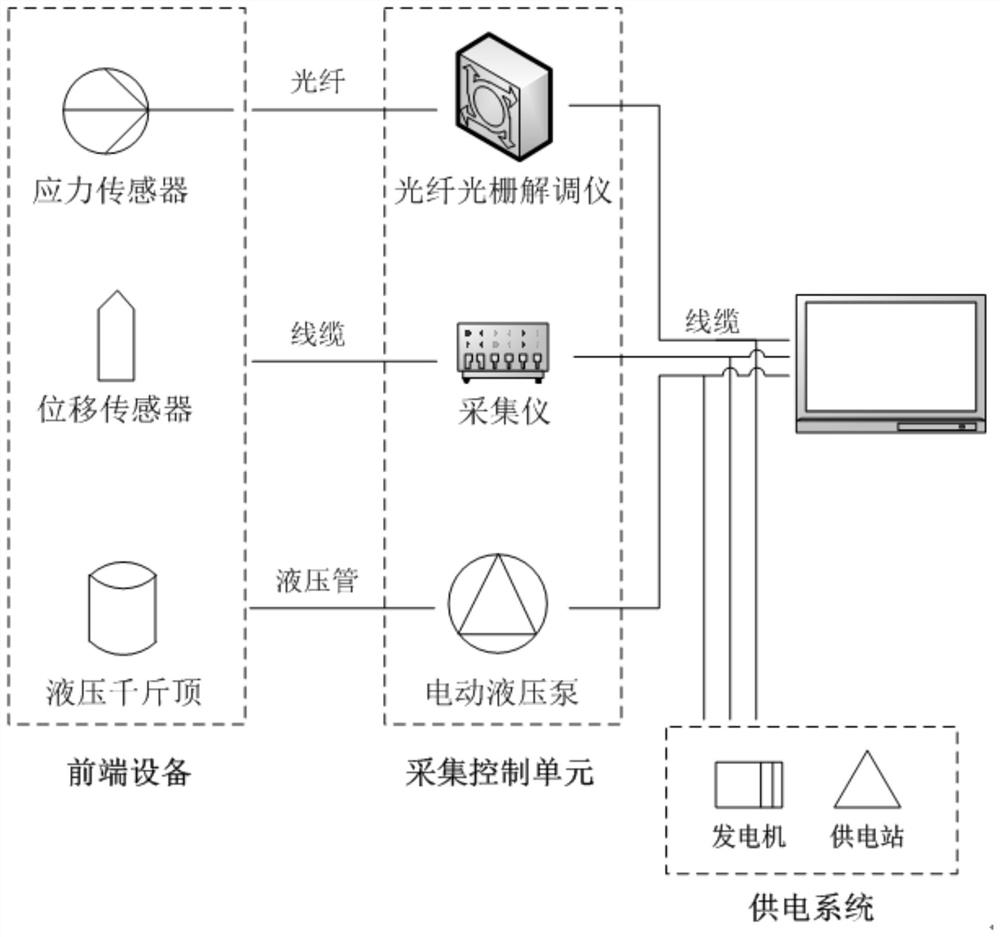

[0046] Such as Figure 4 Shown, the present invention also provides a kind of implementation method of railway bridge top girder monitoring, it is characterized in that, comprises the following steps:

[0047] (1) Determine the equipment parameters and quantities of hydraulic jack 4, displacement sensor 3 and stress sensor.

[0048] (2) Carry out on-site installation according to the equipment installation instructions and site conditions, and test the equipment before and after installation to ensure that the equipment is not damaged and stable.

[0049] (3) Assembly and testing of the railway bridge top girder monitoring system to ensure the normal operation of the system.

[0050] (4) Set the pressurization and pressure release parameters of the hydraulic jack 4 and the displacement sensor 3, and set the pressurization process to 3 levels. According to the characteristics of the rail 7, the stress increase value of the rail 7 reaching the predetermined top beam height is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com