Air pressure drive type ice ball machining device

A processing device and a pneumatically driven technology, which is applied in the field of pneumatically driven ice hockey processing devices, and can solve the problems of high risk, slow speed and poor practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

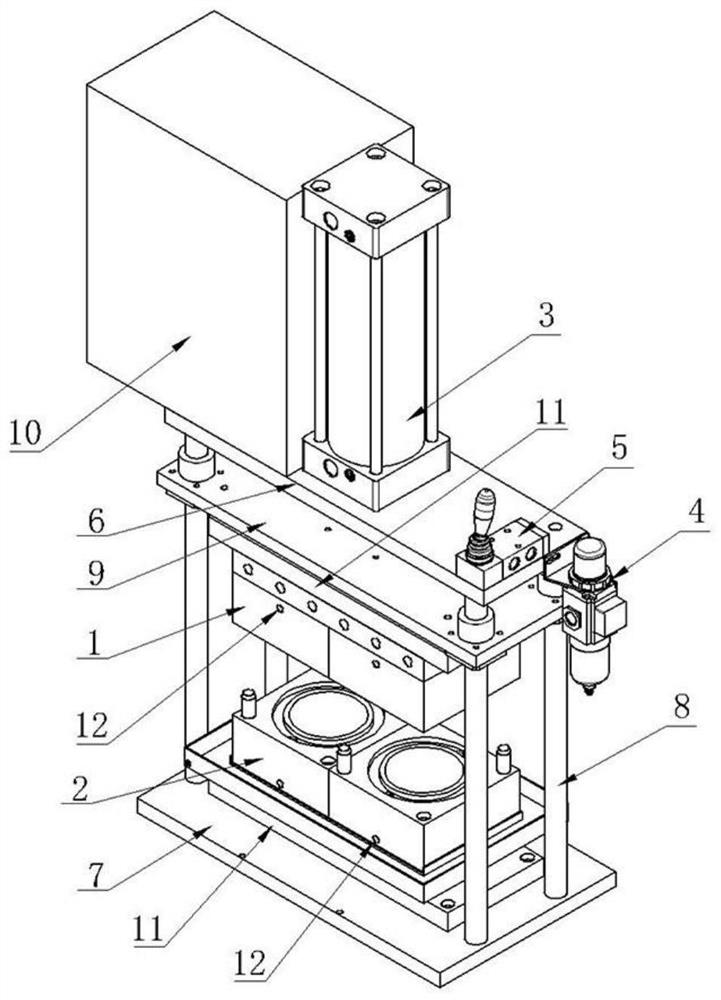

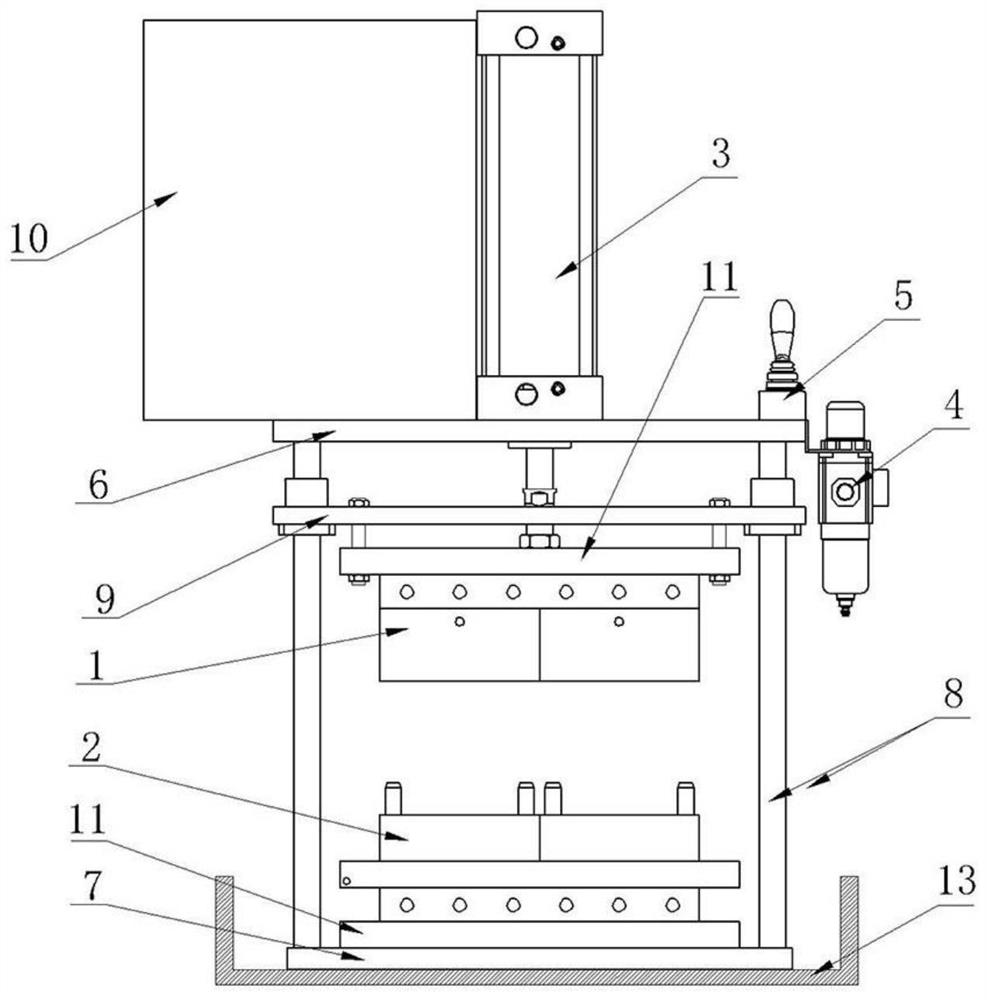

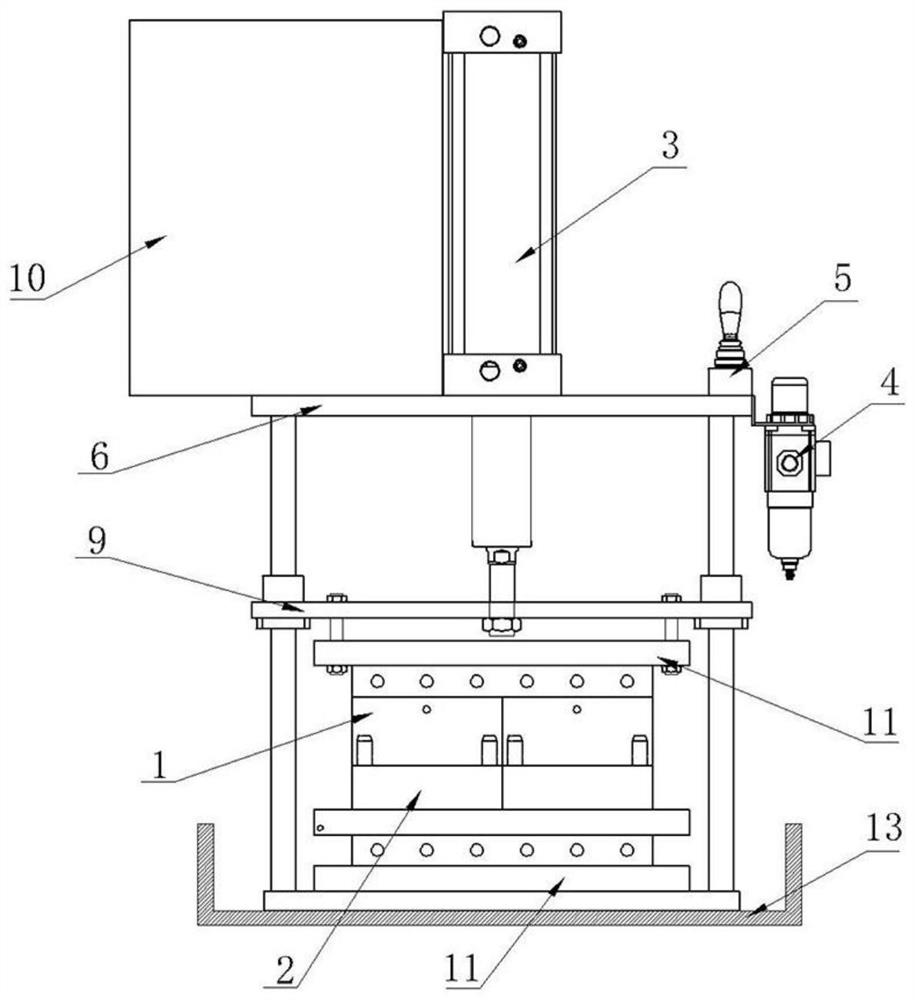

[0020] Such as figure 1 , figure 2 , image 3 A pneumatically driven ice hockey processing device shown includes an extrusion upper die 1, an extrusion lower die 2, pneumatic components and a die frame, and the die frame supports the extrusion upper die and the extrusion lower die; the pneumatic Components include a driving cylinder 3, an air gauge 4 and an air brake switch 5, the air brake switch 5 controls the start and stop of the driving cylinder 3, and the air pressure gauge 4 shows the air pressure leading to the driving cylinder 3; the mold frame includes a top plate 6, a bottom plate 7, Slide rail frame 8 and upper mold slide plate 9, described slide rail frame 8 is four and is vertically fixed on the base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com