Detection method and detection structure for grouting density of prefabricated part

A technology of prefabricated components and detection methods, which is applied to structural elements, building components, measuring devices, etc., can solve the problems that the quality of grouting cannot be directly reflected, and the compactness of grouting materials in confined spaces is difficult to control. fill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

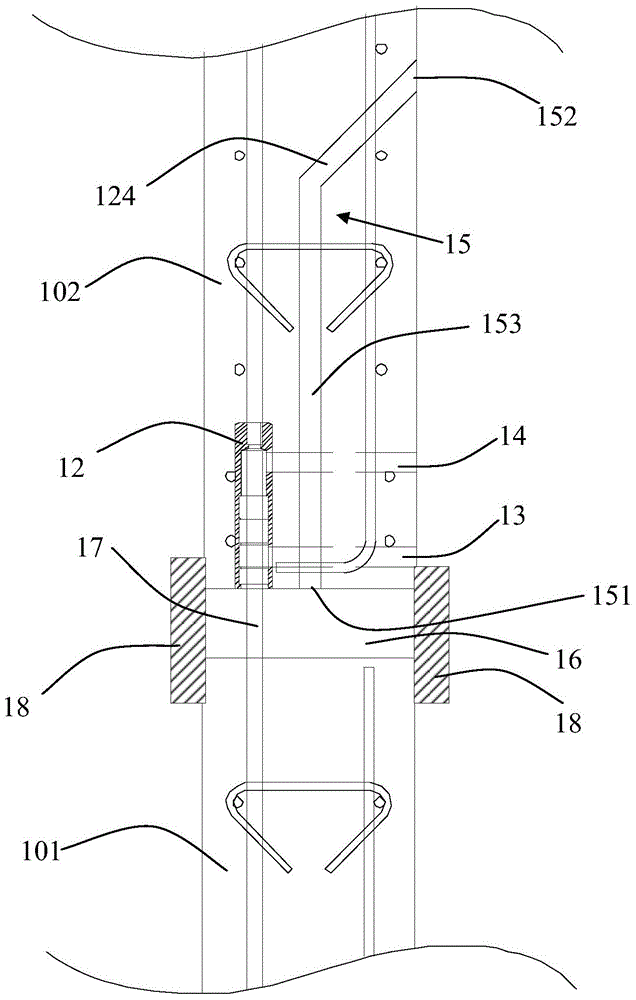

[0038] see first figure 1 and figure 2 As shown, the detection structure of the grouting compactness of the present invention mainly consists of a first prefabricated component 101, a second prefabricated component 102, a plurality of prefabricated measuring points 11, and a signal receiver connected to the prefabricated measuring points 11 (in the figure signal receiver not shown), and a grouting structure.

[0039] Wherein, a grouting construction joint 16 is reserved between the first prefabricated component 101 and the second prefabricated component 102, and a relative grouting interface is formed between the first prefabricated component 101 and the second prefabricated component 102;

[0040] The prefabricated measuring points 11 are pressure sensors or liquid sensors, which are arranged in an orderly manner and are dissatisf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com