Heating device and heating method utilizing oil temperature of transformer of new energy station

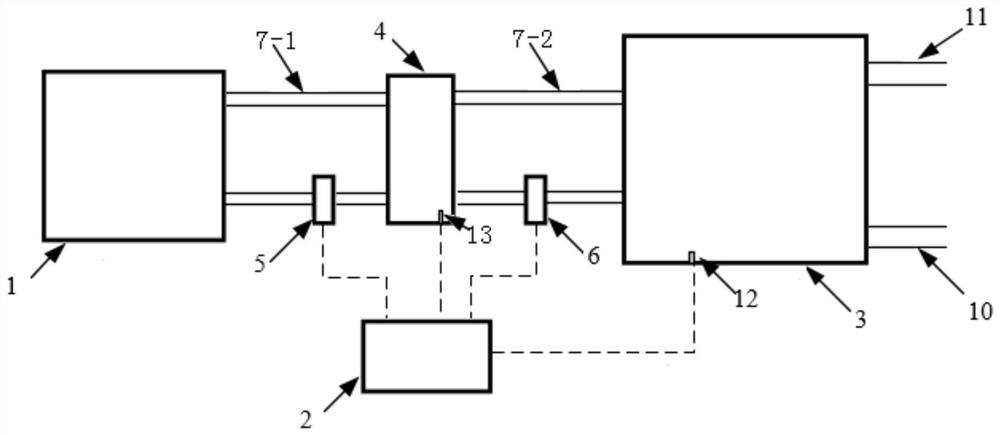

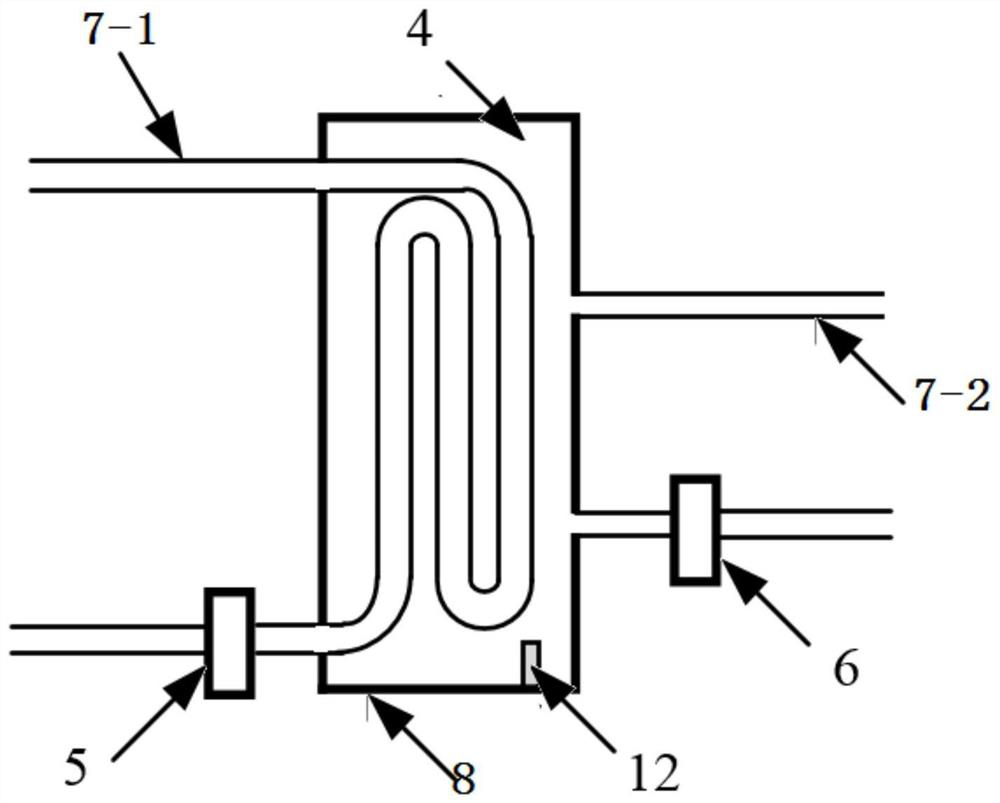

A technology for heating devices and transformers, which can be used in household heating, application, and household heating, etc. It can solve the problems of transformer waste heat dissipation and waste, and achieve the effects of reducing emissions, simple structure, and avoiding thermal pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Taking a 180MVA on-load tap oil-immersed water-cooled transformer installed in an underground 220kV substation as an example, the maximum heat dissipation load borne by the oil-water heat exchanger of a single transformer is 550kW, and the flow rate of the water pump on the cooling water side is 98m 3 / h, the cooling water inlet temperature is 52°C, and the outlet water temperature is 57.4°C. The cooling water pipe is copper alloy pipe with a nominal diameter of 200mm. It can be seen from the above that under normal circumstances, the waste heat generated by the operation of the transformer is sufficient to meet the needs of the winter heating load of the substation of this scale. Set the temperature of the outlet water after heat exchange to 65°C. When the heat exchange is used for domestic hot water and winter heating, the hot water after heat exchange can be directly used for room heating and domestic hot water.

[0039] The present invention is a heating device that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com