Special-shaped joint pipe

A technology for special-shaped joints and joint pipes, applied in the field of pipelines, can solve the problems of no disclosure of hollow steel plates, no disclosure of flow paths around foam plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

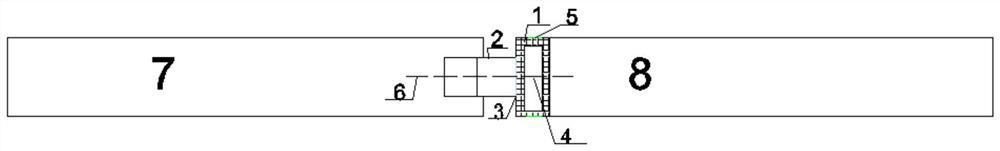

[0032] The main drainage pipe of the infrastructure of a certain community, the drainage pipes leading from each residential building need to be connected to the main drainage pipe. Junction pipes must be used at the junction. If the traditional joint pipe is used, the engineering quantity is large, the structure is complex, the size requirements are strict, and the size of the joint pipe cannot be selected according to the actual situation on site.

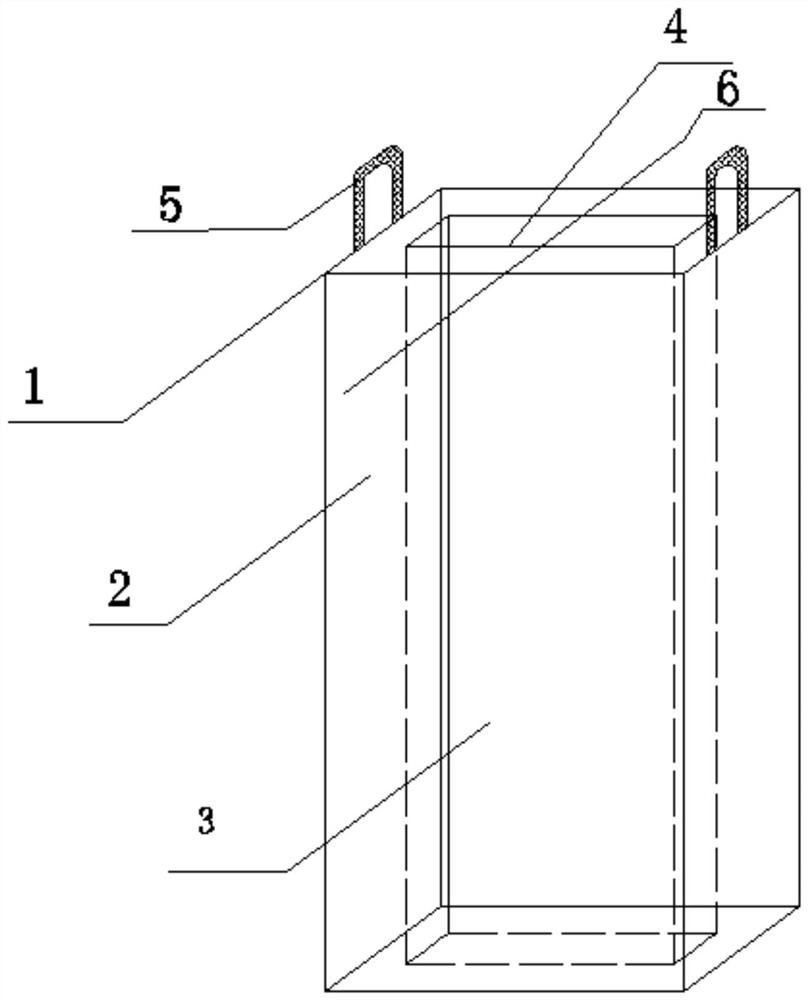

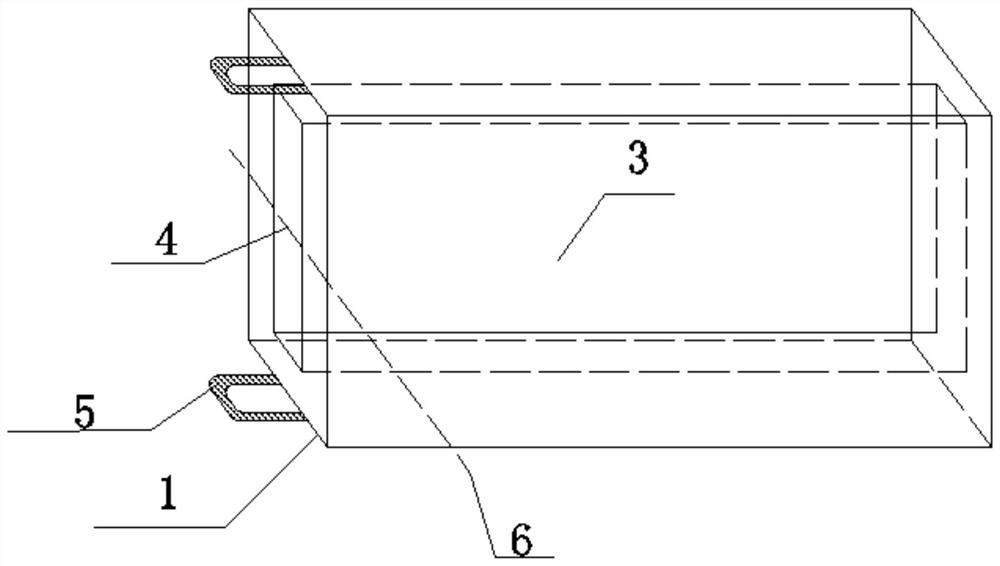

[0033] Therefore, the special-shaped joint pipe described in this application is adopted. as attached figure 1 Shown, a special-shaped joint pipe, including steel plate, foam board and strong glue. The steel plate is made of 45# steel with an average thickness of 5mm. The foam board is made of polyurethane with an average thickness of 20mm.

[0034] The steel plate and the foam board are bonded by strong glue, enclosing a cavity in the form of a basic rectangle to form a hollow part. The hollow part is roughly a hollow rectan...

Embodiment 2

[0043] The water guide channel of a certain tunnel guides the overflow of various parts into the drainage channel to discharge, so as to ensure the safety of the tunnel lining. The special-shaped joint pipes used include steel plates, foam boards and strong adhesive glue. The steel plate is made of stainless steel with an average thickness of 10mm, the foam board is made of polyurethane with an average thickness of 25mm, and the strong adhesive glue forms the bonding layer, and the inorganic super glue is used.

[0044] The steel plate and the foam board are bonded by strong glue, enclosing a cavity in a substantially circular form to form a hollow part. The hollow part is approximately 18mm in diameter and 220mm in height. The outer side of the hollow part is steel plate, and the inner side is foam board. The upper end of the steel plate is provided with lifting lugs, the lifting lugs are provided with hanging earrings, and the hanging earrings are basically arched (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com